Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tablets and capsules with advanced bathless technology, minimizing downtime and ensuring consistent results for quality control and R&D applications.

Performs Rapid Disintegration Testing for Pharmaceuticals

The DT50 Bathless Disintegration Unit from SOTAX embodies innovative technology designed for precise disintegration testing in pharmaceutical and biotech labs. This unit employs patented induction heating technology, significantly reducing heating times to 3-5 minutes, and eliminating labor-intensive cleaning tasks. With automatic end-point detection, it guarantees reliable monitoring, making visual oversight unnecessary. Perfectly suited for various applications such as aspirin tablets, gelatin capsules, and medical device coatings, the DT50 ensures efficient testing with precise control. Its scalability and modular design allow integration with up to two independent stations and a MediaPrep station. The intuitive color touch screen and wireless basket systems facilitate ergonomic and fast handling. Additionally, the DT50 is equipped with q-doc® data management software integration, ensuring compliance with 21 CFR Part 11 for secure data handling. This versatile unit is an ideal fit for pharmaceutical manufacturers and research facilities focused on high-throughput, precise disintegration testing.

Benefits

- Minimizes testing downtime with rapid induction heating, reducing wait times.

- Increases efficiency by eliminating manual oversight through automatic endpoint detection.

- Enhances flexibility with scalable and modular system configurations.

- Ensures regulatory compliance with seamless data management and 21 CFR Part 11 integration.

- Facilitates user-friendly operation with intuitive touchscreen controls and quick-change basket systems.

- Applications

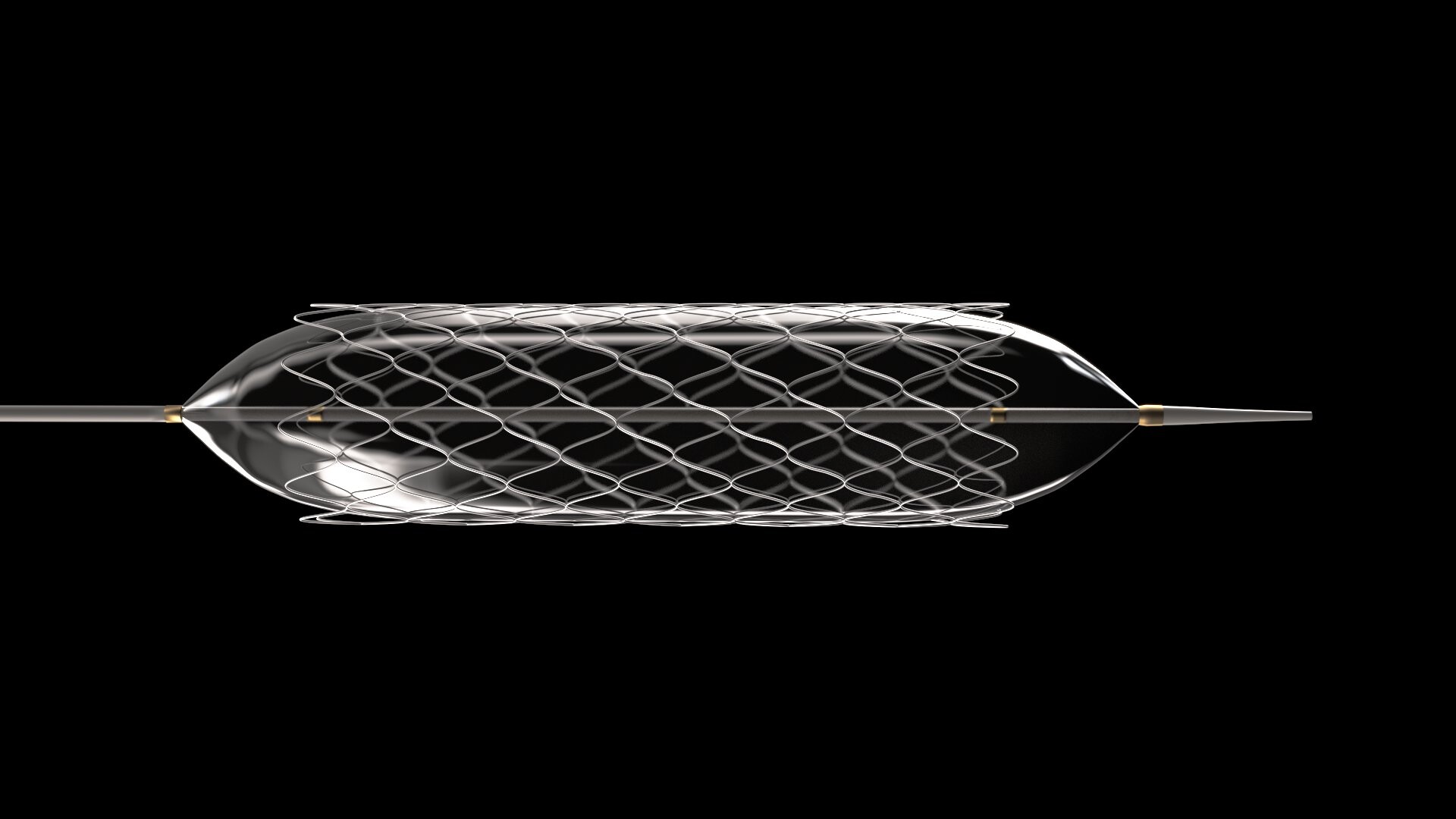

- Medical devices, Gels, Pellets, Microspheres, Catalysts, Stents, Food, Nano suspensions, Fine chemicals, Soft-gelatin capsules, Implants, Animal health, Capsules, Washtabs, Transdermal patches, Creams, Suppositories, Semi-solids, Tablets, Injectable suspensions

- End products

- Gelatin capsules, Antifungal creams, Anti-inflammatory gel, Veterinary antibiotics, Dishwasher tablets, Pain-relief transdermal patches, Enzyme catalysts, Fish oil soft-gel capsules, Chemotherapy injectable solutions, Coronary stents, Hormone-replacement suppositories, Insulin nanosuspensions, Protein supplements, Aspirin tablets, Hip implants

- Steps before

- Tablet Pressing, Capsule Filling, Sample Preparation

- Steps after

- Data Analysis, Quality Control, Report Generation

- Input ingredients

- tablets, capsules, pellets, soft-gelatin capsules, suppositories, medical devices, stents, implants, microspheres, nano suspensions, injectable suspensions, semi-solids, gels, creams, transdermal patches, washtabs, fine chemicals, catalysts

- Output ingredients

- disintegrated tablets, disintegrated capsules, recorded disintegration times

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Heating Time

- 3 - 5 minutes

- Temperature Monitoring

- Permanent, without delay

- Automation

- Automatic test start and end-point detection

- Basket Recognition

- Automatic, with protocolled basket type and serial number

- Modularity

- Extendable up to 2 independent stations

- Residual Height Programming

- Individually programmable

- Control Interface

- Color touch screen

- Data Management Integration

- q-doc® software, 21 CFR Part 11 compliance

- Temperature Control

- Induction heating technology

- Disintegration Time Protocol

- Automatic recording per tablet

- Heating time

- 3 - 5 minutes

- End-point detection

- 100% automatic

- Temperature monitoring

- Permanent

- Automated test start

- Upon reaching target temperature

- Modularity

- Add stations as needed

- Residual height programmability

- Individually programmable

- User interface

- Intuitive color touch screen

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Residual Height Programming

- Capsules and other dosage forms

- USP Certification

- USP <701>

- Compact footprint

- Yes

- Control panel type

- Intuitive color touch screen

- Baskets

- Wireless, self-centering magnetic coupling

- Basket recognition

- Automatic recognition, protocol

- Footprint

- Not specified

- Control panel type

- Color touch screen

- Integration with data management software

- q-doc®

- Scalability,Modularity

- Up to 2 independent stations

- Wireless Baskets

- Self-centering magnetic coupling

- Residual Height Programmability

- Individually for capsules and dosage forms