Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking systems, designed to enhance efficiency in various batch and continuous processes while preserving the quality and structure of delicate end-products such as sauces, creams, and gels.

Cools, Cooks, and Pasteurizes Efficiently

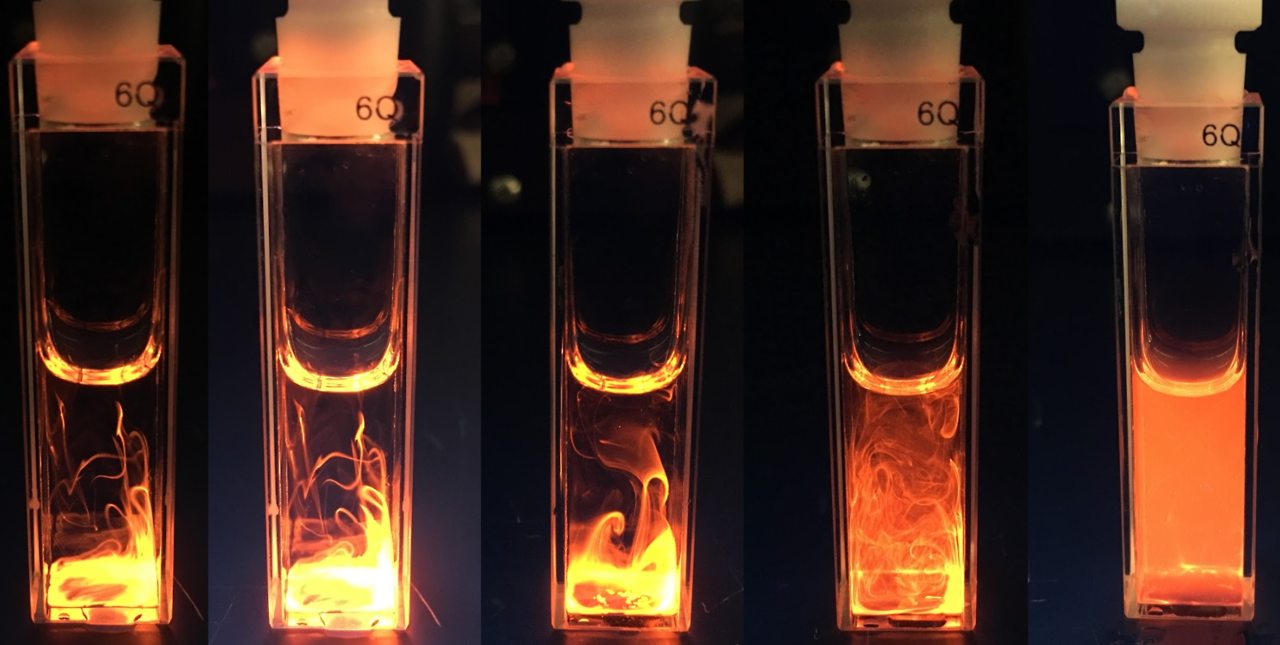

ProXES’ Terlocool and Terlotherm heat exchangers are engineered for versatile applications in the food, health, and advanced materials sectors. These systems excel in precise temperature management, utilizing a double-jacketed design for efficient heat exchange, allowing you to conduct cooling and cooking processes within a single unit. Achieving high throughput, the Terlocool supports up to 2,400 liters per hour, while the Terlotherm can manage up to 10,000 kg per hour, catering to both batch and continuous operations. With applications ranging from hummus and soups to personal care products and chemical suspensions, these units integrate seamlessly into your production line. They offer indirect cooling, pasteurization, and crystallization, ensuring product integrity with gentle agitators. Energy-efficient and customizable, they are available in corrosion-resistant materials, suitable for diverse processes and environments. Featuring compliance with industry standards, these units simplify cleaning and maintenance with options for CIP systems, ensuring hygiene and reduced downtime.

Benefits

- Enhances production flexibility with integrated cooling and cooking processes in one unit.

- Increases operational efficiency by managing high throughput capacities in both batch and continuous modes.

- Maintains product quality through gentle agitation, preserving structure and ingredients.

- Offers energy savings with optimized heat transfer design, reducing operating costs.

- Simplifies maintenance and ensures cleanliness with options for CIP systems.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Quick-dry nail polish, Omega-3 soft gels, Beef stew, Vegan cheese, Black mascara, Bread, Infant formula, Emulsion paint, Red lipstick, Roasted red pepper dip, Organic dog food, Antibacterial ointment, Moisturizing body lotion, Energy drinks, French mustard, Hazelnut spread, Aloe vera gel, Alfredo sauce, Synthetic motor oil, Herbicide solution, Milk chocolate truffles, Porcelain tiles, Chickpea hummus, Hydrating eye gel, Tartare sauce, Apple pie shower gel, Garlic cream cheese, Fruit jam filling, Glossy wood varnish, Vegetable soup, Whitening toothpaste, Foundation cream, Tomato ketchup

- Steps before

- Heating, Cooking, Deaerating, Emulsifying, Homogenizing

- Steps after

- Pasteurizing, Sterilizing, Packing

- Input ingredients

- hummus, savoury spreads, ketchup, table sauces, stews, soups, vegan ingredients, dairy, fruit, vegetables, confectionery materials, pastry ingredients, potatoes, creams, lotions

- Output ingredients

- cooled hummus, processed savoury spreads, chilled ketchup, pasteurized table sauces, ready stews, homogenized soups, vegan product, processed dairy, cooked fruit, vegetables, crystallized confectionery, cooked pastry, mashed potatoes, finished creams, prepared lotions

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- 2, 400 l/hour

- Capacity

- 10, 000 kg/hour

- Functions

- Indirect cooling

- Functions

- Pasteurization

- Functions

- Cooling

- Functions

- Heating

- Functions

- Crystallization

- Functions

- Cooking

- Working Mechanism

- Indirect Cooling

- Integrated Steps

- Pasteurization, Cooling, Heating

- CIP Principles

- Batch Cooling

- Batch vs. Continuous Operation

- Batch and Inline Continuous

- Agitator Type

- Gentle Agitators

- Automation Level

- PLC Controlled

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- SCADA / ERP Integration

- Cooling configuration

- Indirect cooling

- Process scalability

- Batch / Continuous

- System compatibility

- FrymaKoruma / Stephan / Terlet systems