Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid foods and personal care products with this precision cooling system, designed to rapidly cool without altering the product’s inherent characteristics, enhancing both shelf life and process efficiency in your production line.

Rapidly Cools and Stabilizes Liquid Products

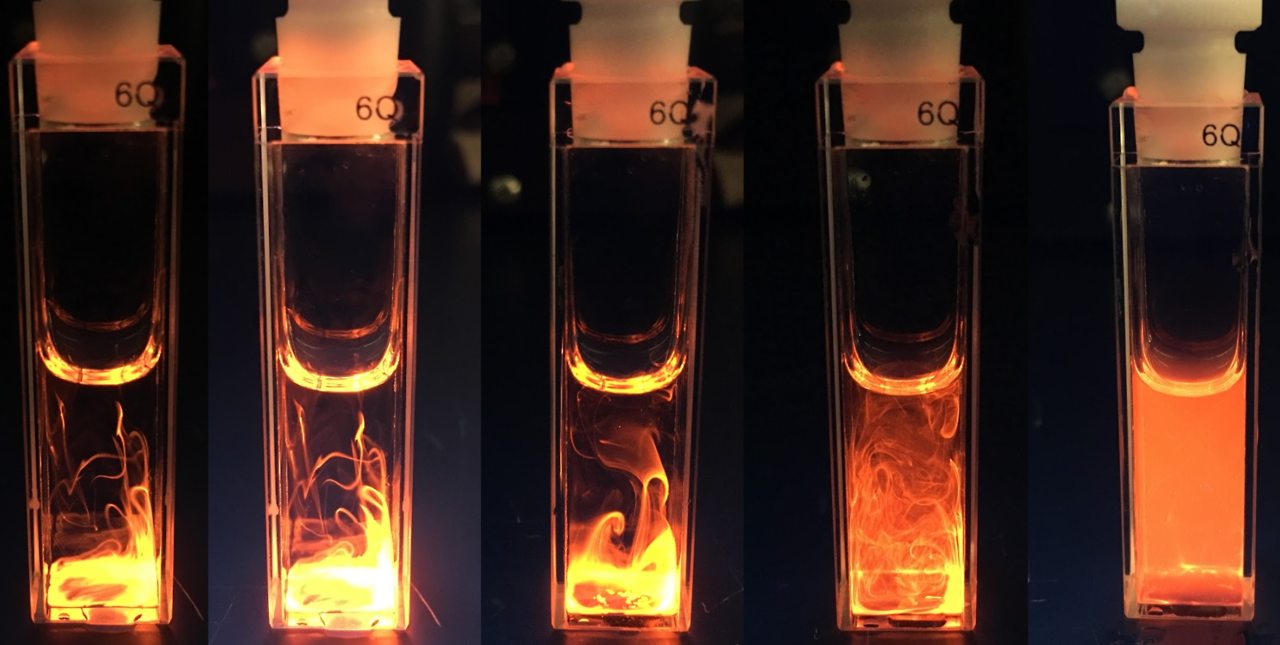

The ProXES Terlocool is a highly efficient liquid cooling system, engineered to meet the stringent requirements of food manufacturers, personal care product producers, and pharmaceutical companies. Utilizing a gentle viscosity-dependent rotation within a tilted double-walled bowl, it ensures homogeneous and gentle cooling, which is crucial for maintaining both taste and texture integrity. Especially effective in cooling post-cooked batches of sauces, spreads, soups, and other viscous liquids, the Terlocool adapts to product viscosity variations for optimal results. This system accommodates volumes between 600–1,200 liters per batch, significantly boosting your production line’s throughput while minimizing downtime with its CIP (cleaning-in-place) technology.

Energy efficiency is a core feature, achieved through optimized heat transfer and segmented scrapers that enhance the rate of cooling. Its automatic vacuum system option not only elevates hygiene standards beyond industry norms but also prolongs product shelf life by inhibiting bacterial growth. Built to integrate seamlessly into existing setups, the Terlocool can be directly interfaced with up- and downstream processing units, enabling continuous and flexible production flows. Constructed from high-grade stainless steel, the system ensures robust corrosion resistance and adherence to GMP and FDA standards for broad industrial applications. Customization options are available to meet diverse processing needs, backed by ProXES’ engineering support for tailored solutions.

Benefits

- Enhances product quality by preserving flavor and texture during cooling.

- Increases production efficiency with rapid cooling and immediate cooker readiness.

- Minimizes contamination risk with automatic CIP cleaning and optional vacuum system.

- Supports extended shelf life by inhibiting bacterial growth.

- Adapts to varied product viscosities, ensuring flexible operation across applications.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Api suspensions, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Vinaigrette, Beef stew, Caramel sauce, Nail lacquer, Engine oil, Almond butter, Body wash, Chocolate ganache, Foundation, Volumizing mascara, Automotive paint, Tomato ketchup, Dijon mustard, Cashew cheese, Mushroom soup, Fluoride toothpaste, Hummus dip, Cod liver oil soft gels, Polymer resin suspension, Hair styling gel, Salsa, Antiseptic ointment, Porcelain ceramic components, Herbal shampoo, Acrylic lacquer, Iced coffee, Aioli, Herbicide solution, Brownie batter, Moisturizing cream, Pharma-grade suspension, Fruit purees, Eye lubricants, Lipstick base, Vegan mince, Cream cheese frosting, Canned dog food

- Steps before

- Cooking, Heating, Emulsification

- Steps after

- Packing, Sterilizing, Pasteurizing

- Input ingredients

- hot sauces, pasta sauces, marinades, hummus, highly viscous foods

- Output ingredients

- cooled sauces, cooled marinades, cooled hummus, cooled products with preserved flavor and texture

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Cooling capacity

- 600–1, 200 liters

- Operation type

- Batch processing

- Cooling speed

- Faster than industry average

- Cleaning technology

- CIP (cleaning-in-place)

- Heat transfer method

- Tilted double-walled bowl with segmented scrapers

- Temperature control

- Viscosity-dependent rotation

- Shelf life extension

- Bacterial growth inhibition

- Hygiene level

- Optional vacuum system

- Working Mechanism

- Batch cooling with tilted double-walled bowl

- Integrated Steps

- Cooling and CIP

- CIP Principles

- Automated cleaning-in-place

- Batch vs. Continuous Operation

- Batch

- Viscosity-dependent Rotation

- Gentle and homogeneous cooling

- Mixing Tool

- Segmented scrapers

- Cooling Efficiency

- High-speed cooling

- Temperature Control

- Adjustable to product viscosity

- Automation Level

- High

- Hygienic System

- Optional vacuum system

- Cleanability

- CIP technology

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Batch Size

- 600–1, 200 liters

- Tilted Double-Walled Bowl

- Yes

- Mixing Tool

- Segmented Scrapers

- Control panel type

- HMI / PLC

- Cooling capacity

- 600–1, 200 liters

- Mixing tool type

- Segmented scrapers

- Integration possibilities

- CIP systems, Vacuum system

- Footprint

- Compact / Space-saving