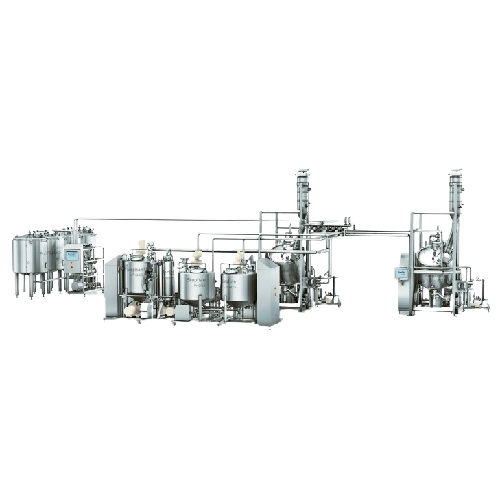

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seamlessly integrate heating, mixing, and cooling processes, ensuring consistent quality across a range of solid, liquid, and slurry products.

Processes and Blends Ingredients Continuously

The Conti Preparation Line from ProXES is a modular system designed for efficient ingredient processing and blending across food, pharma, and personal care applications. This equipment stands out for its seamless integration into production lines, utilizing advanced multi-stage processing to handle operations from emulsifying to vacuum cooking. Ideal for generating a range of products like ketchup, moisturizing creams, and ceramic suspensions, it offers a capacity of up to 4,000 kg/hour, catering to both solid and liquid product types. The line is fully PLC-controlled, enabling precise automation and integration, with options for remote monitoring. Energy efficiency is enhanced through optimized motor controls, while material construction options such as stainless steel ensure high corrosion resistance and compliance with industry standards like GMP and FDA. Additionally, its CIP system facilitates quick and effective cleaning, while customization options are available to meet specific production needs, supported by ProXES’ engineering team.

Benefits

- Enhances production efficiency with continuous operation and high processing capacity.

- Reduces energy consumption by utilizing optimized motor controls.

- Ensures high product quality consistency across varied product types and applications.

- Minimizes labor costs through fully automated PLC control and remote monitoring.

- Complies with GMP and FDA standards for safe and reliable operation in regulated industries.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Api suspensions, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Petfood, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Omega-3 soft gels, Weed killer, Barbecue sauce, Nail lacquer, Plant growth fertiliser, Anti-dandruff shampoo, Engine oil, Exterior wall paint, Body wash, Volumizing mascara, Antibacterial ointment, Wood varnish, Caesar dressing, Hummus dip, Dog food pellets, Paint thinner, Croissants, French mustard, Cream cheese spread, Lip balm, Aloe vera gel, Fruit juices, Saline eye drops, Chocolate spread, Tomato soup, Plant-based burger patties, Porcelain tiles, Moisturizing cream, Antibiotic liquid suspensions, Rice cereal, Pesto, Chocolate bars, Whitening toothpaste, Foundation cream

- Steps before

- Purification, Melting, Dosing, Pre-heating, Ingredient Dosing, Feeding, Soaking

- Steps after

- Cooling, Vacuum Cooling, Evaporation, Buffering, Sieving, De-aeration, Packaging

- Input ingredients

- fat, starch, cheese, ingredients for caramel, chili ingredients, hummus ingredients, mustard seeds, nuts, vegetables, tahina ingredients

- Output ingredients

- caramel filling, processed cheese, chili sauce, hummus, mustard, ready-to-use therapeutic food, vegetable purees, tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Caramel Line

- Capacity

- Cheese Line

- Capacity

- Chili Line

- Capacity

- Hummus Line

- Capacity

- Mustard Line

- Capacity

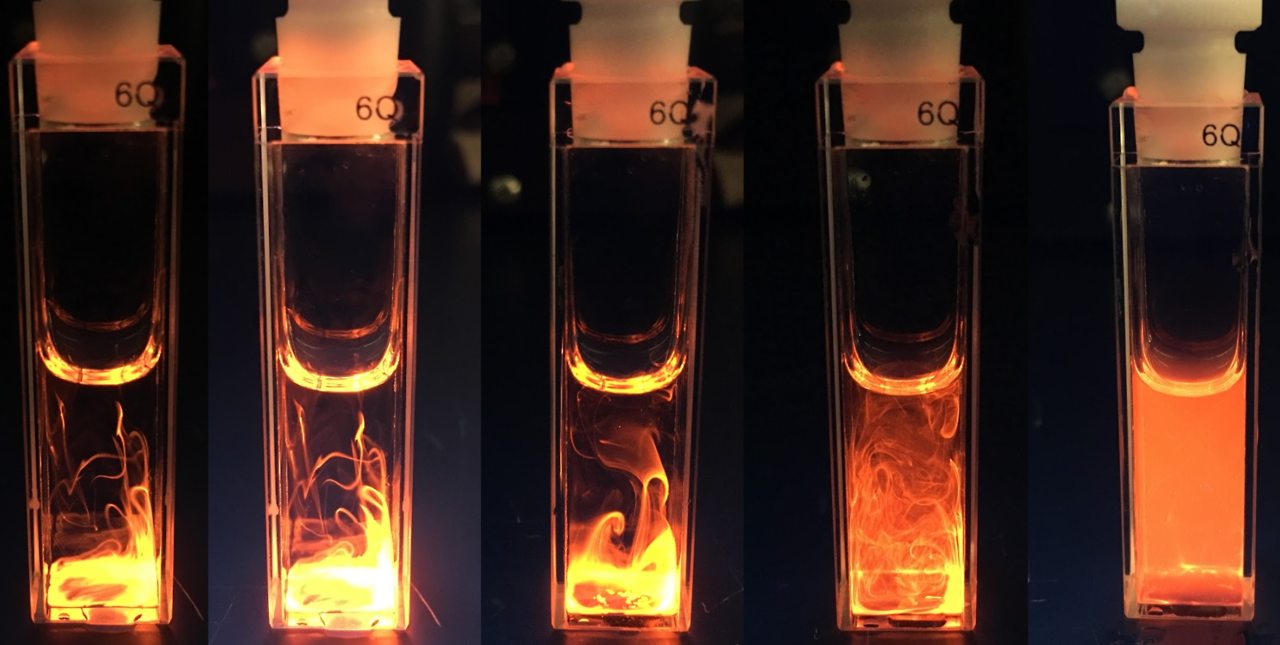

- Nut Paste Line

- Capacity

- Puree Line

- Capacity

- Tahina Line

- Heating Temperature

- Cheese Line

- Cooling Temperature

- Cheese Line

- Vacuum Cooking

- Caramel Line

- Pressurized Cooking

- Caramel Line

- Vacuum Cooling

- Caramel Line

- Deaeration

- Cheese Line, Mustard Line

- Flash Cooking

- Cheese Line

- Type of Grinding

- Mustard Line

- Cooling

- All lines

- Melting

- Caramel Line

- Starch Dissolving,Cooking

- Caramel Line

- Ingredient Dosing

- Caramel Line

- Mixing

- Chili Line, Hummus Line, Nut Paste Line

- Cutting

- Chili Line, Hummus Line, Nut Paste Line, Puree Line

- Soaking

- Mustard Line

- Sieving

- Mustard Line

- Feeding

- Hummus Line, Mustard Line, Tahina Line

- Buffering

- Chili Line, Hummus Line, Nut Paste Line

- Grinding

- Tahina Line

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Conical / Cylindrical

- Tank size

- 50–5000 L

- Discharge method

- Bottom / Side

- Feed method

- Manual / Automatic

- Control panel type

- Touchscreen / Buttons

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / ERP systems

- Machine configuration

- Modular / Custom

- Recipe management

- Programmable

- Footprint

- Customizable according to space