Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensuring precise product sterilization and versatile format adaptability for a wide range of liquid applications.

Fills and Sterilizes Liquid Products

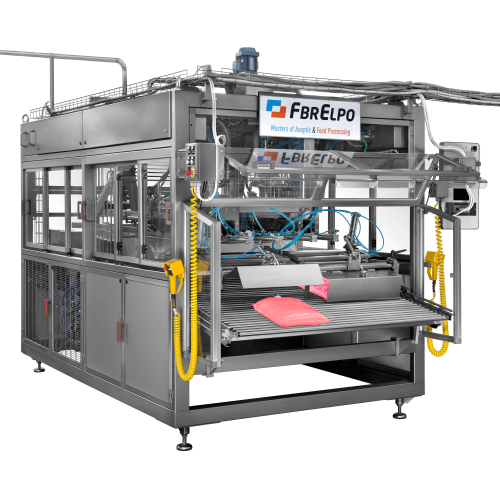

The MUSTANG Aseptic Filler from FBR ELPO offers a sophisticated solution for aseptic filling in the food and beverage industry. Constructed from stainless steel, it features a double filling head and operates at a capacity of up to 1,200 bags per hour. This filler uniquely accommodates a variety of liquid products, including milk, juices, creams, and tomato-based products, in bag sizes ranging from 1.5 to 20 liters.

Designed for flexibility, it can handle diverse cap configurations using steam or chemical agents for cap sterilization. Its seamless integration into existing production lines is enhanced by direct receiving from a sterilizer, eliminating the need for an intermediate aseptic tank. Additionally, the adjustable cutter and sliding doors streamline format changeovers and space management. Equipped with remote assistance capabilities, the MUSTANG Aseptic Filler enables diagnostics and parameter adjustments via an internet connection. This feature ensures optimal operations and minimal downtime, making it a key asset for facilities requiring high-speed, continuous, and automatic filling solutions.

Benefits

- Increases operational efficiency with a production capacity of up to 1,200 bags per hour.

- Enhances product integrity by accommodating a wide range of bag sizes and cap types.

- Minimizes downtime through seamless integration without the need for an intermediate aseptic tank.

- Ensures consistent filling accuracy of ±0.5%, optimizing product yield and quality.

- Facilitates remote troubleshooting and updates, reducing maintenance costs and operational disruptions.

- Applications

- Liquid formulations, Natural fruit juices, Ice-cream bases, Dairy products, Tomato products, Tea, Creams

- End products

- Green tea, Whipped cream, Milk, Apple juice, Tomato puree, Chocolate ice cream base, Orange juice, Tomato paste, Vanilla ice cream mix, Black tea, Heavy cream, Yogurt

- Steps before

- Sterilization, Product Reception

- Steps after

- Packing, Box Insertion, Diagnostics, Program Monitoring, Parameter Modification

- Input ingredients

- liquid products, products with pieces, low acid products, high acid products, milk, cream, ice-cream basis, natural fruit juices, fruit concentrates, tea, tomato

- Output ingredients

- aseptic bags, pre-sterilized bags, bags with spouts, pre-mix dispensing pipes, post-mix dispensing pipes

- Market info

- FBR ELPO is known for its expertise in manufacturing industrial equipment, specializing in engineered-to-order solutions for food and beverage processing, particularly in thermal processing and aseptic technology, and holds a strong reputation for innovation and reliability in the market.

- Filling speed

- Up to 1, 200 bags/h

- Filling volume

- 1.5 to 20 L

- Filling accuracy

- ±0.5% of filled volume (min. ±30 ml)

- Product filling temperature

- +5°C to +45°C

- Dimensions

- Width

- Material

- Stainless steel

- Automation

- Completely automatic

- Bag type

- Pre-sterilized bags

- Cap sterilization method

- Chemical agents and/or steam

- Automation level

- Automatic

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- Steam / Chemical agent sterilization

- Changeover time

- Fast regulation

- Cleaning method

- Chemical / Steam

- Remote-assistance capability

- Yes, via internet

- Filling purpose

- Liquid and pieces, low and high acid

- Container type

- Bag in Box from 1.5 to 20 L

- Spout type compatibility

- Short neck / Long neck

- Machine Footprint

- Width

- Machine Material

- Stainless Steel

- Filling Head Type

- Double Head

- Spout Compatibility

- Short Neck / Long Neck

- Remote Assistance

- Internet Connection

- Cap Sterilization Method

- Chemical / Steam