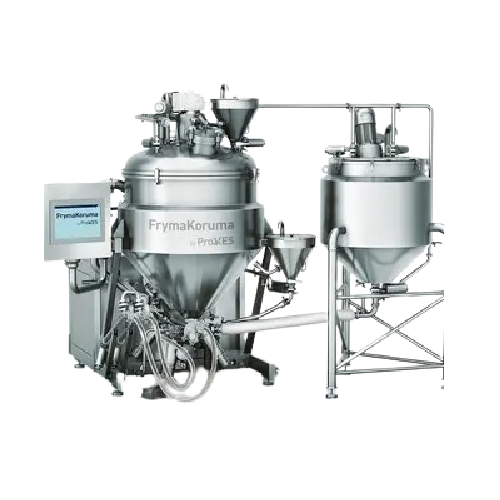

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capacity solution, designed for seamless integration into continuous processing lines. Ideal for achieving precise texture and stability in complex formulations like mayonnaise and cosmetic creams.

Mixes, Emulsifies, and Homogenizes Diverse Product Formulations

The MaxxD from ProXES is a high shear emulsifier designed for diverse industrial applications, offering exceptional precision in mixing, emulsifying, and homogenizing. This equipment utilizes rotor-stator technology to ensure even distribution and texture consistency, integrating seamlessly into your existing production line. Ideal for food, pharmaceutical, cosmetic, and chemical sectors, it processes capacities up to 5,000 kg/hour. The MaxxD supports continuous and batch operations, handling a wide range of viscosities in products like sauces, creams, and lotions. Its PLC-controlled system enables efficient automation with options for remote monitoring, empowering you to optimize operations with precision. Constructed from stainless steel, it offers superior corrosion resistance, meeting industry standards such as GMP and FDA. The built-in CIP (Clean-In-Place) system ensures efficient cleaning between batches, minimizing downtime. Customizable configurations are available to tailor the system to your unique production requirements, backed by comprehensive engineering support from ProXES.

Benefits

- Enhances product quality with consistent texture and stability across diverse formulations.

- Reduces energy consumption by utilizing optimized motor control and variable-speed operations.

- Increases operational efficiency with seamless integration into existing production lines and automation capabilities.

- Lowers maintenance costs with a robust stainless-steel design and efficient CIP cleaning system.

- Ensures regulatory compliance with GMP and FDA standards, facilitating broader market access.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Petfood, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Beef stew, Dog kibble, Olive tapenade, Infant formula, Smoothies, Dijon mustard, Exfoliating shower gel, Caesar dressing, Organic pesticide, Nitrogen fertilizer, Anti-aging lotion, Polymer dispersions, Croissants, Dark chocolate, Cream cheese spread, Lip balm, Aloe vera gel, Herbal shampoo, Saline eye drops, Alfredo sauce, Antifungal ointment, Tomato soup, Omega 3 soft gels, Acrylic paint, Plant-based burger patties, Porcelain tiles, Chocolate hazelnut spread, Chickpea hummus, Lithium grease, Moisturizing cream, Waterproof mascara, Automotive lacquer, Gel nail polish, Fruit jam, Whitening toothpaste, Liquid foundation, Tomato ketchup

- Steps before

- Cooling, Heating, Crystallizing, Deaerating

- Steps after

- Homogenizing, Dispersing, Sterilizing, Pasteurizing, Packing

- Input ingredients

- mayonnaise ingredients, dressings components, sauce bases, ketchup pre-mix, cosmetic formulations, pharmaceutical compounds, cream mixtures, ointment ingredients, gel formulations, toothpaste mix, soy slurry preparation, rice slurry preparation, oat slurry preparation, nuts and seeds paste

- Output ingredients

- emulsified mayonnaise, finished dressings, completed sauces, processed ketchup, manufactured cosmetics, sterile pharmaceuticals, creams, ointments, gels, prepared toothpaste, mixed soy slurry, mixed rice slurry, mixed oat slurry, nuts and seeds paste, chemical suspensions, lubrication grease

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Up to 85, 000 l/hour

- Capacity

- Up to 40, 000 kg/h

- Capacity

- Up to 5, 000 kg/hour

- Capacity

- Up to 6, 000 kg/h for full-fat mayonnaise

- Capacity

- Up to 4, 000 kg/h for low-fat mayonnaise

- Oil dosing

- Up to 3.0 kg/s

- Specific energy input

- On average 5 kWh/ton

- Batch volume

- 500 l

- Dimensions

- L 230 x H 280 x W 210 cm

- Weight

- Approx. 2, 000 kg

- Functions

- Homogenizing, mixing, dispersing, emulsifying, heating, cooling, cleaning, deaeration, sterilization

- Working Mechanism

- Rotor-stator system

- Integrated Steps

- Homogenizing, mixing, dispersing, heating, cooling, cleaning, deaeration, sterilization

- Batch vs. Inline Flow

- Batch and Inline

- Automation Level

- Manual / PLC controlled

- CIP Principles

- CIP system

- Energy Efficiency

- 5 kWh/ton (average)

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Suitable for corrosive materials

- Abrasion resistance

- High

- Biological compatibility

- Food Grade, Pharma Grade

- Density/particle size

- 0.5–2.5 g/cm³

- Container size

- Small / Medium / Large

- Consistency

- Thick / Thin / Viscous / Fluid

- Machine Footprint

- L 230 x H 280 x W 210 cm

- Capacity

- 85, 000 l/hour (Inline), 40, 000 kg/h (Inline), 5, 000 kg/h (Stand-alone)

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- PLC / SCADA / MES

- Discharge method

- Pump / gravity

- Cooling option

- Integrated / external

- Automation level

- Semi-automatic / fully automatic