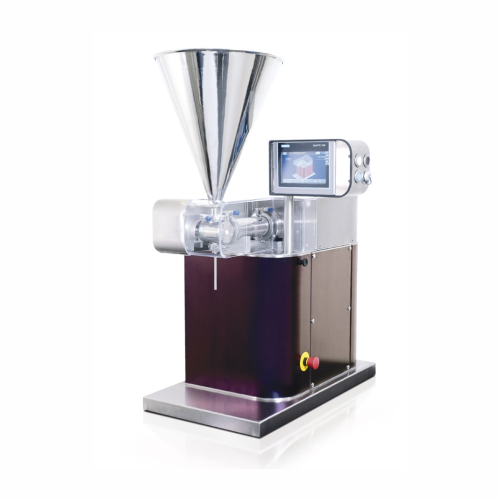

Lab-scale liquid and cream filling system

Streamline your lab production with precise filling of liquids, creams, and pastes, ensuring consistent batch quality without the need for frequent part changes.

Fills and Packages Liquid, Creamy, and Pasty Products

The e-FILLY Series from Marchesini Group offers a versatile laboratory solution designed to fill and package liquid, creamy, and pasty products without the hassle of part replacements. It operates using a servo motor, enhancing precision and control, and features fully electronic operation, eliminating the need for compressed air. This system is specifically tailored for cosmetic manufacturers, providing seamless automation across the filling, capping, labelling, and end-to-end packaging process, including cartoning and palletising. With adjustable suction and batch speeds, it can accommodate both intermittent and continuous cycles, allowing for flexible manufacturing in a range of laboratory and industrial settings. Its capability to handle volumes from 2 to 250 ml makes it ideal for producing items such as sunscreen lotion, moisturizing cream, and gel-based hand sanitizer. Further, the e-FILLY Series supports Wi-Fi remote control via the D-connect® app, enabling monitoring and adjustments through smartphones or tablets, which streamlines operations and enhances productivity. Available as a bench-top unit, it integrates effortlessly into existing lab setups and is supported by comprehensive engineering and customization options to meet specific production needs.

Benefits

- Enhances flexibility with adjustable suction and batch speeds.

- Eliminates the need for compressed air, reducing operational costs.

- Streamlines processes with Wi-Fi remote control via smartphone or tablet.

- Facilitates seamless lab integration with compact bench-top design.

- Minimizes maintenance and increases uptime with electronically controlled operation.

- Applications

- Pasty products, Creamy products, Liquid products

- End products

- Hair conditioner, Gel-based hand sanitizer, Sunscreen lotion, Body butter, Shampoo, Tomato paste, Moisturizing cream, Facial cleanser

- Steps before

- Emulsification, Grinding, Mixing, Blending

- Steps after

- Packing, Labelling, Cartoning, Over-Wrapping

- Input ingredients

- liquid products, creamy products, pasty products

- Output ingredients

- filled tubes, filled jars, filled containers, filled bottles

- Market info

- Marchesini (Dumek) is renowned for designing and manufacturing advanced engineered-to-order equipment for the pharmaceutical and cosmetics industries, focusing on innovation, quality, and customization to meet specific client needs efficiently.

- Capacity

- 2–250 ml

- Automation

- Servo motor/electronic control

- Cycle operation

- Intermittent/continuous

- Control

- Wi-Fi remote control via Tablet and Smartphone with dedicated APP D-connect®

- Speed adjustment

- Independent suction and batch speeds

- Electricity usage

- Electric running

- Working mechanism

- Electric running with servo motor

- Automation level

- Electronic control with touch panel

- Batch vs. continuous operation

- Intermittent or continuous cycle

- Changeover time

- Independent suction and batch speed adjustment

- Remote operation

- Wi-fi control via Tablet and Smartphone

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- 2 – 250 ml

- Control panel type

- Touch panel

- Control Panel Type

- Touch panel

- Integration Possibilities

- Wi-fi remote control via Tablet and Smartphone

- Motor Type

- Servo motor

- Cycle Operation

- Intermittent or continuous cycle

- Filling Range Capacity

- 2 – 250 ml

- Automation

- Totally electronic, does not use compressed air