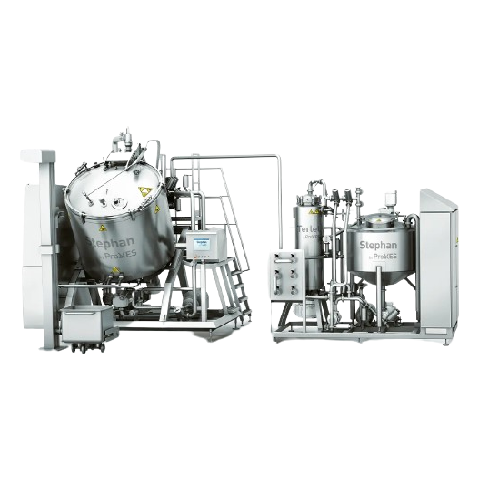

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat melting, starch dissolving, and vacuum cooking for enhanced flavor and consistency.

Processes and Prepares Diverse Food and Pharma Products

The continuous processing and preparation line from ProXES integrates the expertise of FrymaKoruma, Stephan, and Terlet, delivering a tailored solution for diverse production demands in food and pharmaceutical industries. This line excels in multi-stage processes, from vacuum cooking and emulsifying to homogenizing, enhancing product consistency and efficiency across applications such as baby food, sauces, creams, and lotions. With capabilities reaching up to 4,000 kg/h, it accommodates high-speed, continuous operations, ensuring seamless integration into existing production lines. The equipment features advanced automation with PLC controls, enabling precise process management and remote monitoring. Constructed from durable stainless steel, it offers excellent corrosion resistance, vital for handling various materials including chemicals and food grade substances. Compliant with GMP and other industry standards, it supports strict quality requirements. Designed with a CIP system, it facilitates efficient cleaning and minimizes downtime, while customization options and engineering support ensure adaptability to specific production environments.

Benefits

- Enhances production efficiency with seamless integration into existing lines.

- Reduces operational costs through energy-efficient processes.

- Ensures high product consistency and quality across diverse applications.

- Supports stringent health and safety compliance with GMP design.

- Minimizes downtime with quick-changeover and easy-to-clean CIP systems.

- Applications

- Sauces, Gels, Bakery, Table sauces, Processed cheese, Pesticides, Ointment, Vegan, Chocolate, Food, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Pharma, Sweet spreads, Lotions, Nail polish, Shower gel, Personal care, Ceramics, Api suspensions, Grease, Fertilisers, Drinks, Advanced materials, Mustard, Baby food, Paints, Lacquers, Fillings, Health, Petfood, Creams, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Lipstick

- End products

- Steps before

- Fat melting, Starch dissolving, Ingredient dosing, Feeding, Soaking, Pre-cutting

- Steps after

- Vacuum cooling, Cooling, Deaeration, Sieving, Buffering

- Input ingredients

- Fat, Starch, Ingredients for caramel, Cheese, Chili ingredients, Hummus ingredients, Mustard seeds, Nuts, Vegetables, Sesame for tahina

- Output ingredients

- Caramel filling, Processed cheese, Chili sauce, Hummus, Mustard, Ready-to-Use Therapeutic Food, Vegetable purees, Tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Caramel Line up to 2, 500 kg/hour

- Capacity

- Cheese Line up to 4, 000 kg/hour

- Capacity

- Chili Line up to 2, 000 kg/hour

- Capacity

- Hummus Line up to 2, 000 kg/hour

- Capacity

- Mustard Line up to 2, 600 kg/hour

- Capacity

- Nut Paste Line up to 1, 500 kg/hour

- Capacity

- Puree Line up to 4, 000 kg/hour

- Capacity

- Tahina Line up to 1, 500 kg/hour

- Heating Temperature

- Up to 145°C (Cheese Line)

- Pre-heating Temperature

- Up to 95°C (Cheese Line)

- Flash-cooling Temperature

- Down to 80–85°C (Cheese Line)

- Functionality

- Fat melting, Starch dissolving, cooking, Ingredient dosing, Vacuum cooking, Pressurized cooking, Evaporation (Caramel Line)

- Functionality

- Cheese blending, Vacuum deaeration, Creaming (Cheese Line)

- Functionality

- Cutting, Mixing, Heating/Cooking, Buffering, Cooling (Chili, Hummus, Nut Paste Lines)

- Functionality

- Feeding, Soaking, Grinding, Cooling, Sieving, De-aeration (Mustard Line)

- Cooking Method

- Vacuum cooking, Pressurized cooking (Caramel Line)

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- High viscosity capability

- Abrasiveness

- Handled in processing

- Foaming Tendency

- Low to moderate

- Heat Sensitivity

- Requires careful temperature control

- Container Size,Shape

- Flexible configuration

- Machine footprint

- Compact

- Tank shape

- Conical / Cylindrical

- Feed method

- Automatic / Manual

- Discharge method

- Pneumatic / Gravity

- Cone size

- Variable

- Control panel type

- Digital / Touchscreen

- Cooling option

- Indirect / Direct

- Control panel type

- HMI / PLC / SCADA

- Integration possibilities

- Modular kit system

- Recipe Management

- Customizable

- Machine Configuration

- Customizable

- Scale Capacity

- Up to 4, 000 kg/h