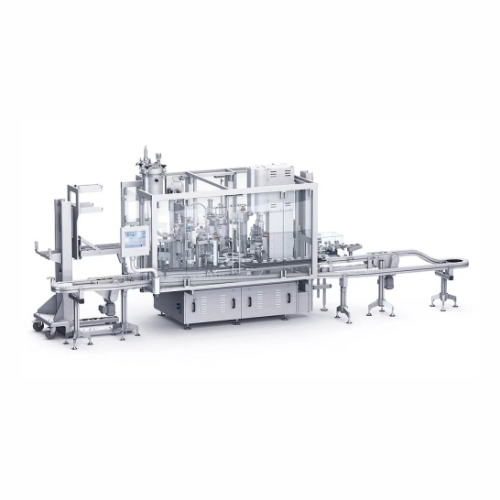

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic containers, ensuring product integrity and packaging efficiency with customizable, flexible configuration options for diverse product lines.

Fills and Seals Creams, Lotions, and Makeup

The Creme 60 from groninger is an engineered-to-order filling and closing line specifically designed for the cosmetics, personal care, and consumer healthcare industries. This versatile equipment excels in handling liquid-based products such as creams, lotions, and makeup, processing various container types, including face cream jars, makeup bottles, and airless containers.

What sets the Creme 60 apart is its flexibility and high-speed capability, achieving up to 60 units per minute. This machine utilizes different filling systems with a rotary piston pump for creamy products, ensuring precise filling without air bubbles. An optional centrifuge station rotates the jars for air-free filling in face creams.

The system integrates seamlessly into continuous production lines with capabilities for heat sealing, screwing, and inspections, ensuring airtight sealing and product integrity. Designed for easy operation and maintenance, the Creme 60 allows for quick changeovers using a change trolley, facilitating continuous production without downtime.

The Creme 60 supports a variety of closing options, including pre and post-screwing stations for screw caps and placement stations for intermediate lids. Its robust construction and accurate filling process control ensure high machine availability and quality in the final product. Groninger offers customization support to meet your changing production needs, while compliance with industry standards ensures operational reliability.

Benefits

- Enhances production efficiency with speeds up to 60 units per minute.

- Maintains product quality by preventing air bubbles through controlled rotary filling.

- Minimizes downtime with quick changeovers using a change trolley system.

- Ensures product integrity and extended shelf life through airtight heat sealing.

- Adapts to diverse product lines with customizable configurations and equipment variants.

- Applications

- Lotion bottles, Mini dispensers, Face cream jars, Makeup bottles, Makeup, Mini rollers, Airless containers, Lotions, Creams

- End products

- Eye cream jars, Acne treatment gels, Facial moisturizers, Foundation bottles, Liquid blushes, Travel-size rollerball serums, Cc creams, Body lotion bottles, Bb creams, Sample cream dispensers, Anti-aging creams, Airless pump skincare bottles

- Steps before

- Emulsification, Product Preparation, Container Washing

- Steps after

- Sealing, Inspection, Packaging, Labeling

- Input ingredients

- face cream, lotion, makeup, creamy products, temperature-controlled products

- Output ingredients

- face cream jars, makeup bottles, airless containers, mini dispensers, mini rollers, lotion bottles

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Speed

- Up to 60 units per minute

- Filling systems

- Different systems with rotary piston pump

- Heat sealing

- Aluminum seal with a sealing head

- Placement stations

- For intermediate plastic and aluminum lids

- Pre and post-screwing

- Left/right screw mode with correct torque

- Container types

- Face cream jars, makeup bottles, airless containers, mini dispensers, mini rollers, lotion bottles

- Filling speed

- Up to 60 units per minute

- Product flexibility

- Face creams, lotions, makeup

- Temperature-controlled filling

- Yes

- Changeover time

- Quick and easy

- Automation level

- High

- Includes pre and post-screwing stations,placement stations

- Modularity

- Equipment variants can be chosen as needed

- Air incorporation control

- Yes, using centrifuge station

- Maintenance

- Easy, includes change trolley

- Sealing method

- Heat sealing

- Container sealing

- Secure and airtight

- Integrated steps

- Blowing out, suction, filling, closing, inspection

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- Face cream jars to lotion bottles

- Container shape

- Jars, bottles, airless containers

- Compact footprint

- Yes

- Machine footprint

- 60 units/min

- Discharge method

- Rotary piston pump

- Control panel type

- Selectable configuration

- Change trolley

- Available

- Filling systems

- Rotary piston pump

- Heat sealing option

- Aluminum seal

- Placement station type

- Plastic lids / Aluminum lids

- Pre and Post-screwing station

- Left/right screw mode

- Change trolley option

- Complete filling line including tank