Continuous heat exchanger for soups and sauces

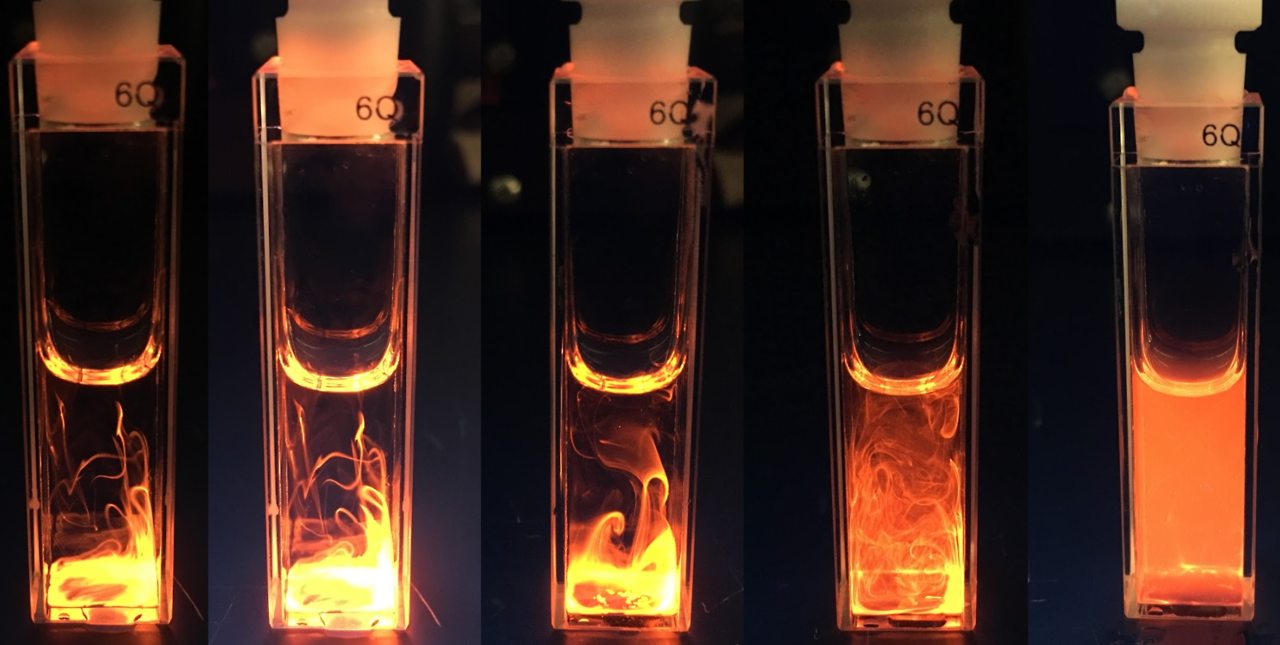

Optimize your soup and sauce production with a continuous heat exchanger that ensures precise temperature control and uniform cooking, reducing the risk of scorching and maintaining consistent product quality.

Processes and Heats Multifunctional Product Batches

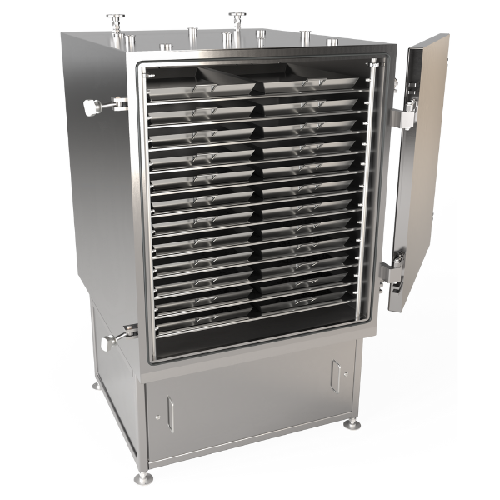

The COOK-IT® series from ProXES GmbH offers an industry-leading solution for manufacturers requiring precise thermal processing capabilities. These cookers and multifunctional heating systems are engineered for seamless integration into production lines, with configurations optimized for processing a wide range of products from baby food to pharmaceuticals. Utilizing direct steam injection and double jacket heating, these systems ensure uniform temperature distribution and minimize scorching risk, maintaining product consistency and quality. With capacities up to 4,800 l/hour, the systems’ versatility is evident in their applications—from emulsifying dressings to pasteurizing sauces. The PLC-controlled operations enable efficient automation and easy integration with existing systems. Constructed from stainless steel, they ensure durability and compliance with hygiene standards, while the CIP system facilitates quick and secure clean-up processes. Customizable to specific product and process requirements, the COOK-IT® series also provides engineering support for bespoke solutions.

Benefits

- Ensures consistent product quality with precise temperature control and even heat distribution.

- Reduces operational costs through energy-efficient direct steam injection and double jacket heating.

- Enhances production flexibility, accommodating a diverse range of food, pharmaceutical, and personal care products.

- Minimizes cleaning time and contamination risk with an integrated CIP system.

- Facilitates seamless integration and operation with PLC-controlled automation and remote monitoring.

- Applications

- Sauces, Gels, Pesticide, Table sauces, Processed cheese, Ointment, Chocolate, Bakery products, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Health products, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Api suspensions, Pet food, Grease, Vegan products, Fertilizer, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Pharmaceuticals, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Lipstick

- End products

- Omega-3 soft gels, Beef stew, Olive tapenade, Tomato bisque, Automotive grease, Organic fertilizer, Spicy ketchup, Foundation creams, Truffles, Bio-pesticide solution, Chocolate ganache, Fruit juice, Antibacterial ointment, Dijon mustard, Exfoliating shower gel, Caesar dressing, Garlic hummus, Anti-aging cream, Baby cereal, Horseradish sauce, Fish oil supplements, Olive oil mayonnaise, Propolis extracts, Croissants, Herbal cough syrup, Mascarpone cheese, Long-lasting lipstick, Aloe vera gel, Herbal shampoo, Porcelain tiles, High-performance lubricants, Marinara sauce, Aloe vera lotion, Waterproof mascara, Blueberry jam, Vegan protein bars, Lubricating eye drops, Wet cat food, Glossy paint, Cheddar cheese spread, Water-resistant lacquer, Gel nail polish, Industrial coatings, Whitening toothpaste

- Steps before

- Emulsification, Grinding, Mixing

- Steps after

- Pasteurizing, Cooling, Crystallization, Packing

- Input ingredients

- low viscous products, baby food, senior food, pureed food, fruit puree, sauces, sauces with particles, soups, fruit preparations, milk desserts, mayonnaise, ketchup, dressings, dips, dairy, fruit, vegetables, confectionery, pastry, potato mash, creams, lotions, convenience food, ganache

- Output ingredients

- stews, soups, sauces, processed cheese, purees, food desserts, mayonnaise, ketchup, dressings, dips, processed cheeses, confectionery goods, pastries, dairy products

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Up to 10, 000 kg/hour

- Heating Temperature

- Up to 145 °C

- Cooling Temperature

- Down to 80…85°C

- Mixing Functions

- Mixing, emulsifying, dispersing

- Heating Method

- Direct steam injection, double jacket heating

- Cooling Method

- Indirect cooling via double jacket

- Vacuum Processing

- Yes

- Batch vs. continuous

- Batch or continuous

- Automation

- CIP/SIP included

- Heat Processing

- Direct and indirect

- Particle Distribution

- Homogeneous

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies based on model and configuration

- Container geometry

- Special container geometry

- Discharge method

- Tiltable vessel

- Control panel type

- PLC/Touchscreen

- Integration possibilities

- SCADA/IoT-ready

- Heating Process Adaptability

- Direct steam injection/Double jacket heating

- Component Adaptability

- Scrapers/Agitators

- Container Geometry

- Individually adapted

- Vacuum Processing

- Available

- Functionality

- Batch or continuous processing

- Agitation system

- Adjustable/Customizable