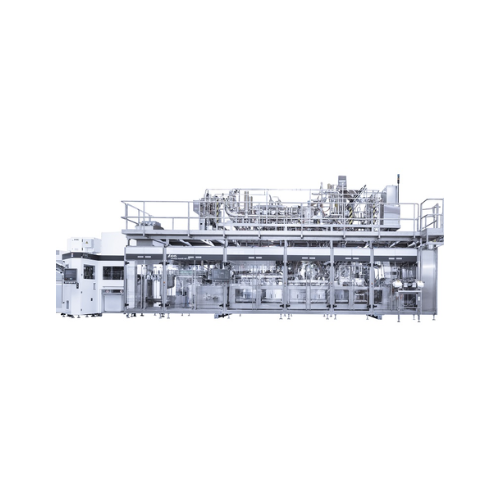

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advanced energy-saving capabilities, ensuring high-quality production for diverse beverage types, from milk to coffee, all while reducing energy consumption significantly. Ideal for manufacturers looking to enhance sensitivity control and product safety in liquid processing.

Fills and Capps Aseptically in High-Speed Operations

The InnoPET BloFill ACF-L from KHS Group is an aseptic linear filling solution designed for diverse liquid processing needs across the beverage and non-food sectors. Specializing in aseptic operations, it integrates seamlessly with existing production lines, utilizing a novel transfer module to connect with standard rotary KHS stretch blow molders for a compact setup. This configuration not only facilitates smaller batch operations for products like milk, juices, and isotonic drinks, but also cuts energy costs by up to 40% through the Double Gate heating concept. With a throughput capacity of up to 14,000 bottles per hour, it accommodates volumes ranging from 100 to 2,000 milliliters, making it adaptable for a wide range of product types. The servo-operated cappers ensure precision capping, with real-time monitoring and automatic rejection of faulty closures to uphold quality standards. Designed for efficiency, the InnoPET BloFill ACF-L incorporates nitrogen dosing for enhanced product stability and shelf life. Built for ease of maintenance and optimal line availability, it supports continuous operation with fast format changeovers under aseptic conditions, making it an ideal choice for manufacturers focused on efficiency and safety.

Benefits

- Optimizes bottling line efficiency with up to 14,000 bottles per hour capacity.

- Cuts operational energy costs by up to 40% through advanced heating technology.

- Ensures product safety and quality with precise aseptic filling and capping.

- Enhances product shelf life with nitrogen dosing stability.

- Facilitates quick product changeovers, maximizing versatility and line availability.

- Applications

- Yogurt beverages, Liquid food, Mixed milk, Milk, Coffee beverages, Non-food products, Vegetable juices, Sports beverages, Fruit juices

- End products

- Household cleaners, Liquid detergent, Strawberry milk), Drinkable yogurt, Apple juice, Tomato juice, Protein shakes, Orange juice, Isotonic sports drinks, Cold brew coffee, Cappuccino iced coffee, Carrot juice, Flavored milk (e.g, Chocolate milk, Whole milk

- Steps before

- Blow molding, Bottle design, Recyclate preparation

- Steps after

- Capping, Labeling, Secondary packaging

- Input ingredients

- milk, mixed milk, sports beverages, yogurt, coffee beverages, fruit juices, vegetable juices, liquid nitrogen, PET bottles

- Output ingredients

- filled PET bottles, capped bottles, sealed bottles

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Capacity

- up to 14, 000 bottles per hour

- Filling volume

- 100 to 2, 000 milliliters

- Flexibility

- Designed for frequent product changeovers

- Energy Efficiency

- Up to 40% energy cost savings with Double Gate heating concept

- Aseptic Safety

- Extremely small aseptic zone

- Closure System

- Plastic screw caps and/or foil seals

- Automation

- Fast format changeovers under aseptic conditions

- Bottle Sterilization

- H2O2 aerosol

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Changeover time

- Fast format changeovers

- Automation level

- PLC-controlled

- Energy efficiency

- Up to 40% energy savings

- CIP/SIP

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- PET bottles

- Filling purpose

- Milk, mixed milk, sports, yogurt and coffee beverages, fruit and vegetable juices

- Container size

- 100 to 2, 000 milliliters

- Filling speed

- Up to 14, 000 bottles per hour

- Compact footprint

- Space-saving design with integrated systems

- Machine capacity

- Up to 14, 000 bottles per hour

- Filling volume range

- 100 to 2, 000 milliliters

- Discharge method

- Blocked with stretch blow molder and aseptic filler

- Aseptic zone size

- Extremely small for maximum safety

- Transfer module

- New transfer module for linear aseptic filler

- Integration with rotary blow molders

- Yes

- Closure system

- Plastic screw caps/foil seals

- Control Panel Type

- PLC-controlled

- Energy-efficient features

- Double Gate heating concept

- Compatibility with bottle sizes

- 100–2, 000 ml