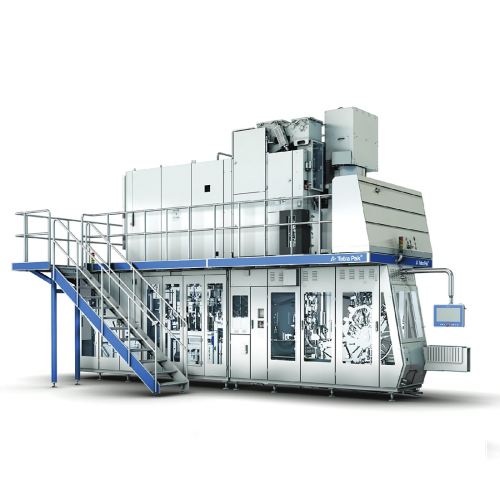

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flexible solution, enabling swift conversions between package types and ensuring sterility with advanced injection moulding and servo-driven technology.

Fills and Seals Aseptic Liquid Packages

The Tetra Pak® A3/Flex is a versatile aseptic filling machine designed specifically for dairy and beverage producers requiring adaptable liquid packaging solutions. This machine excels with its servo-driven technology, enabling rapid conversions between different package shapes and sizes without compromising sterile conditions. Supporting applications across various industries, it handles products ranging from whole milk and soy milk to fruit juices and plant-based beverages. Capable of continuous, high-speed operation, the A3/Flex integrates seamlessly into your production line, offering automated and precision-controlled filling, sealing, and packaging processes. The iLine automation platform ensures communication with upstream and downstream equipment, while the PLMS centre aids in performance analysis, optimizing production efficiency. Notably, the machine is energy-efficient, designed to minimize power and peroxide consumption through its compact aseptic zone. Enhanced with hygienic features and FDA-filed aseptic process, it guarantees high food safety standards while offering options like QuickChange for rapid production adjustments and Direct Injection Moulding for innovative closure solutions. Configurable for specific needs, the Tetra Pak® A3/Flex also supports easy maintenance and cleaning, offering a smart, adaptable solution for modern production lines.

Benefits

- Increases production efficiency with seamless package size and shape transitions.

- Enhances operational continuity by eliminating production halts for material refilling.

- Lowers energy costs through reduced power and peroxide consumption.

- Ensures superior food safety with FDA-filed aseptic processes.

- Minimizes product waste with optimized servo-driven jaw system and precise package alignment.

- Applications

- Sauces, Cheese, Tomato products, Whey, Baby food / infant formula, Dairy, Food, Soups, Desserts, Ice cream, Spreads, Still drinks, Plant-based products, Fruit preparations / jams, Powder, Dairy alternative, Juice, Nectar, Dips, Dressings

- End products

- Infant formula, Chocolate mousse dessert, Herbal iced tea, Whey protein powder, Caesar dressing, Cheese slices, Peanut butter spread, Hummus dip, Orange juice, Almond milk, Apple jam, Yogurt, Creamy tomato soup, Milk, Apple nectar, Marinara sauce, Chocolate ice cream, Soy milk, Tomato ketchup

- Steps before

- Packaging material preparation, Sterilization of packaging material, Product formulation, Product pre-processing

- Steps after

- Package sealing, Quality inspection, Labeling, Distribution and logistics

- Input ingredients

- packaging material, sterile air, inert gas, liquid products (e.g., juice, milk), aseptic packaging components, control cabinet, heating element

- Output ingredients

- Tetra Pak packages, aseptic cartons, sealed packages, headspace for shaking, sterilized packages

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Automation

- PLC-controlled

- Aseptic process

- Unique FDA filed

- Production continuity

- Uninterrupted

- Sterilisation method

- Deep peroxide bath

- Servo driven jaw system

- Software modelled

- Operator interface

- Intuitive touch screen

- Operational control

- PLMS centre

- Integration level

- iLine automation platform

- Filling volume

- 500 ml – 2000 ml

- Package types

- Tetra Brik® Aseptic, Tetra Stelo® Aseptic, etc.

- Flexibility

- QuickChange technology

- Headspace creation

- Headspace by Injection

- Opening method

- DIMC on PLH, PullTab Unit

- Conversion time

- 15 minutes with QuickChange

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC / SCADA

- Changeover time

- 15 minutes

- CIP/SIP

- Unique aseptic process FDA filed

- Cleaning method

- CIP

- Easy conversion

- Between different package shapes and sizes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- FDA compliance

- FDA filed unique aseptic process

- Compact footprint

- 4.3m high, 20m² footprint

- Control panel type

- Tetra Pak Operator Panel with touch screen interface

- Discharge method

- Packages released in an upright position

- Control panel type

- Touch screen interface

- Integration possibilities

- iLine automation platform

- QuickChange technology

- Rapid switch between package types

- Servo driven jaw system

- Software based profile adjustment