Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confectionery with advanced flexibility, optimizing for various product shapes and quick adjustments in your production line.

Molds Chocolate and Confectionery Precisely

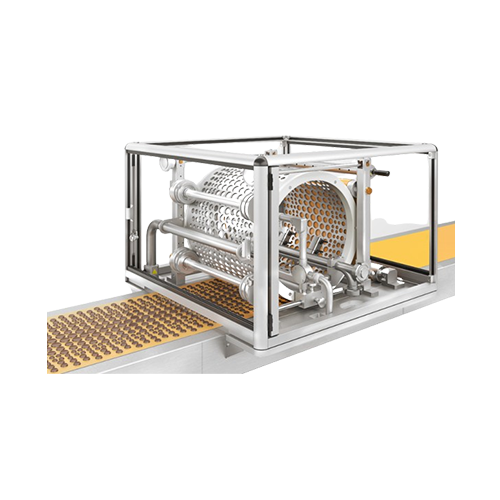

The Sollcodrop® from Sollich KG is a precision mold forming system, expertly crafted to address the demands of chocolate and confectionery manufacturers. This equipment stands out due to its volume-precise molding capabilities, allowing for the creation of an extensive range of motifs in products such as chocolate pralines, nougat bars, and decorative figures. Utilizing state-of-the-art molding technology, it ensures accurate weight shaping and quick format changes, enhancing productivity and flexibility in production lines.

With a working width from 420 mm to 1300 mm and a working speed of up to 10 meters per minute, it fits seamlessly into high-speed, continuous operations typical in the confectionery industry. The Sollcodrop® is engineered for easy cleaning, reducing downtime and maintenance overheads. Additionally, its design incorporates energy-efficient features, optimizing operations for reduced energy consumption.

Its compatibility with various materials, including chocolate and fat masses with or without ingredients, makes it a versatile solution for producing diverse products, from granola bars to chocolate-dipped ice cream bars. Available with options for customization and integration, the Sollcodrop® can be tailored to meet specific production needs, supported by Sollich KG’s engineering expertise.

Benefits

- Enhances production flexibility with quick format changes and precise motif molding.

- Increases efficiency by integrating seamlessly into high-speed, continuous operations.

- Minimizes downtime through easy cleaning and maintenance.

- Optimizes energy usage, reducing operational costs and environmental impact.

- Supports diverse product output, accommodating a wide range of confectionery applications.

- Applications

- Biscuits, Brittle bars, Fat masses, Dragees, Pralines, Decorative articles, Confectionery, Fruit bars, Cereal bars, Sweets, Candy bars, Ice cream, Chocolate, Protein bars

- End products

- Chocolate truffles, Nougat bars, Muesli bars, Fruit and nut bars, Granola bars, Chocolate-dipped ice cream bars, Chocolate-covered biscuits, Chocolate pralines, Energy protein bars, Caramel-filled chocolates, Decorative chocolate figures, Yogurt-coated dragees, Chocolate-coated almonds, Chocolate dragees, Peanut brittle

- Steps before

- Grinding, Flavour and Colour Dosing, Mixing, Sieving, Emulsification

- Steps after

- Cooling, Enrobing, Packing, Sprinkling, Coating

- Input ingredients

- chocolate, fat masses, ingredients

- Output ingredients

- moulded motifs, products up to 6 mm in height

- Market info

- Sollich is known for manufacturing engineered-to-order equipment for the confectionery industry, particularly chocolate processing and enrobing machines. They have a strong reputation for innovation, quality, and tailored solutions to meet specific customer requirements.

- Working Width

- 420–1300 mm

- Working Speed

- up to 10 m/min

- Product Height

- up to 6 mm

- Accuracy

- Volume-precise moulding

- Automation

- Quick format change

- Cleanability

- Easy cleaning

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Quick format change

- Cleaning method

- CIP / Easy cleaning

- Energy efficiency

- High efficiency

- Cleanability

- Easy cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Working width

- 420 up to 1300 mm

- Working speed

- up to 10 m/min

- Control Panel Type

- Touchscreen / Button Interface

- Integration Possibilities

- PLC / SCADA Integration

- Quick Format Change

- Yes

- Easy Cleaning

- Yes

- Working Width Range

- 420 mm to 1300 mm

- Working Speed

- Up to 10 m/min