Almond Processing Equipment

Find innovative production technology for making almonds and connect directly with world-leading specialists

From being grown in the field to roasting and slicing, the manufacture and processing of almonds is a multi-tiered operation. After removing their hull, also known as almond hulling, you can process almonds in various ways to achieve the requested consistency. Whether you chop the almond, finely mill them or turn them into almond milk, they require special care and equipment for nut processing.

Innovative solutions for almonds

Almond and apricot kernel blanching solution

Efficiently remove hulls from blanched almonds and apricot kernels to streaml...

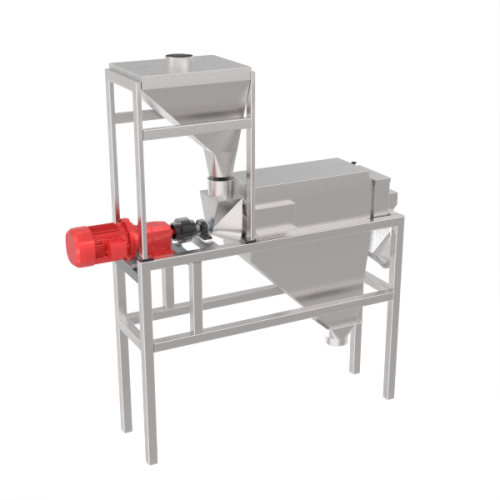

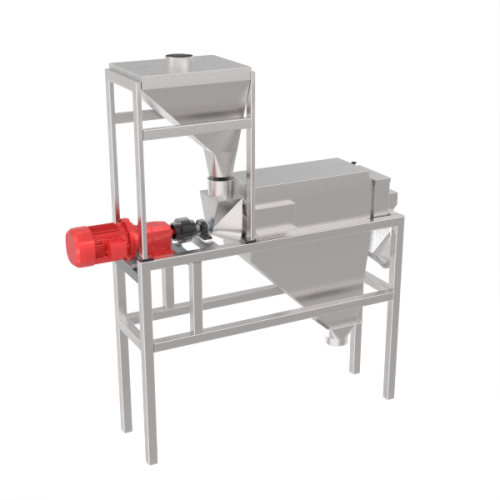

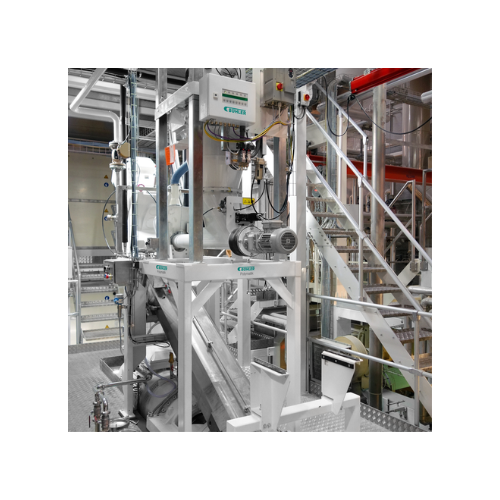

Almond hulling system for soft and semi-hard shells

Efficiently hull almonds with soft or semi-hard shells to streamline ...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

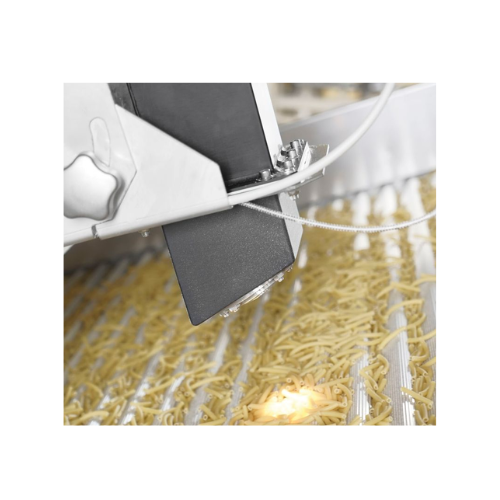

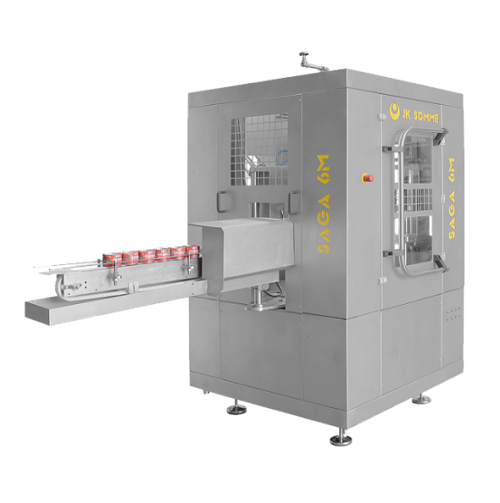

Industrial almond slicer for nut processing

Achieve precise nut slices with adjustable thickness, perfect for enhancing pa...

Select your almonds process

Tell us about your production challenge

Almond processing equipment for all shapes and sizes

Almonds are rich in fiber, protein, magnesium, and vitamin E, making them a quick and healthy snack. To make them, you can use various chopping, slicing, shelling, and grating equipment.

To create lush chocolates and pralines, for instance, opt for smaller chunks of almond nuts. You can adjust your almond processing equipment for chopping and slicing to produce the preferred size of the almond. After that, add the chopped nuts to trail mixes, chocolates, cakes, and other food products.

Almond equipment for making milk and flour

To produce almond milk and flour, manufacturers use almonds that do not achieve specific aesthetic requirements. They collect these as the material is separated in the sorters.

You make almond flour by grating almond nuts with an industrial nut grater. The flour is then sifted to ensure its powdery texture. This is the main ingredient in French macarons, first concocted in Venetian monasteries and brought to the French court by Catherine de Medici.

Integrate hullers in the almond processing line to separate contaminants

There are two methods of almond milk manufacturing, and you should consider both when deciding on processing equipment and technology. The ‘dry’ method includes adding water to grated almonds. The ‘wet’ method process consists of blending soaked almonds with water.

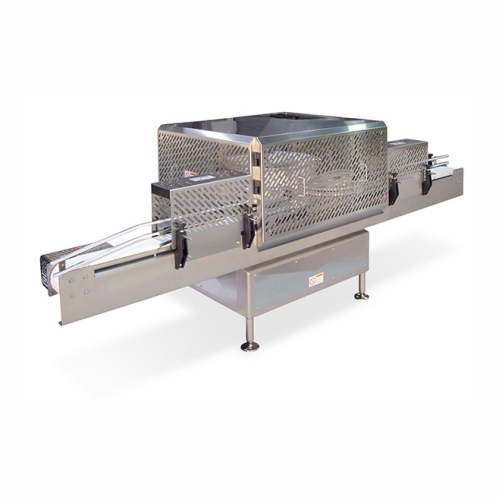

Almond shelling also occurs in this step to avoid unwanted material in the milk. Manufacturers often pasteurize the milk with tunnel pasteurizers to eradicate pathogens and prolong its shelf-life. Automation equipment makes the process faster. This leads to a safer and higher quality product.

Almond nuts retain plant-based milk status

Almond milk has had its fair share of controversy. In an attempt to ban the use of the word ‘milk’ in connection to kinds of milk, part of the dairy industry submitted Amendment 171 to the European Parliament.

Lawmakers rejected it in 2021, so almond milk is still considered milk in the EU.

Almond milk is not just for making your favorite latte

Rich in vitamins E, B2, and B3, almond milk has been a valued ingredient in cosmetic products for decades. It also has moisturizing and skin-healing properties, lightening dark spots and healing acne scars. You can use almond milk in soaps, shampoos, body lotions, and the like.

To further process almond milk, you need specialized mixing equipment to reduce and evenly distribute almond milk particles into a liquid, emulsion, or cream. Add the nut milk into laboratory-grade mixers with the rest of the ingredients and watch as they create the desired texture of soaps, lotions, shampoos, and creams.

Processing steps involved in almonds making

Which almonds technology do you need?

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

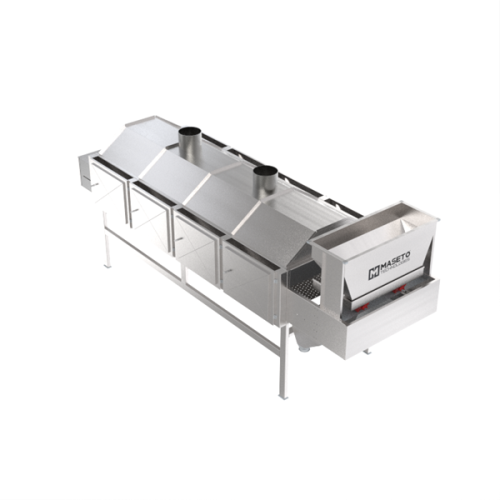

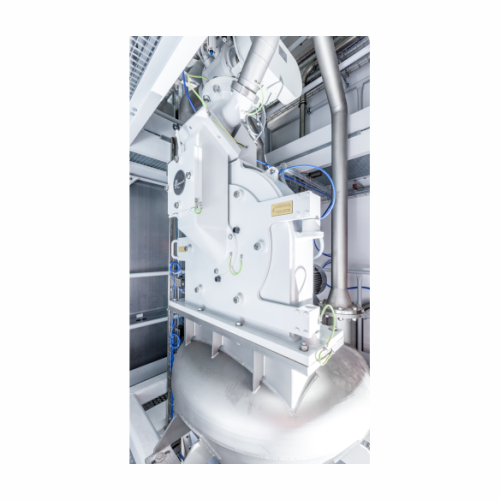

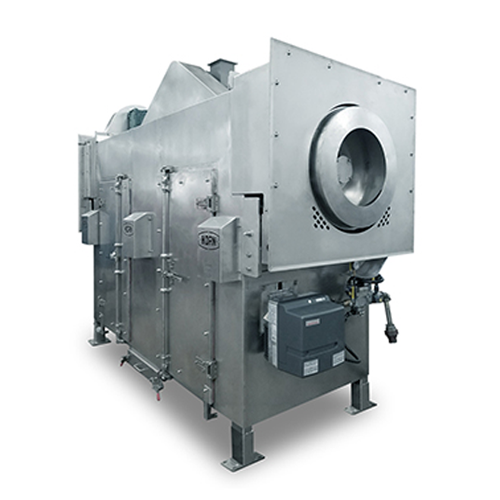

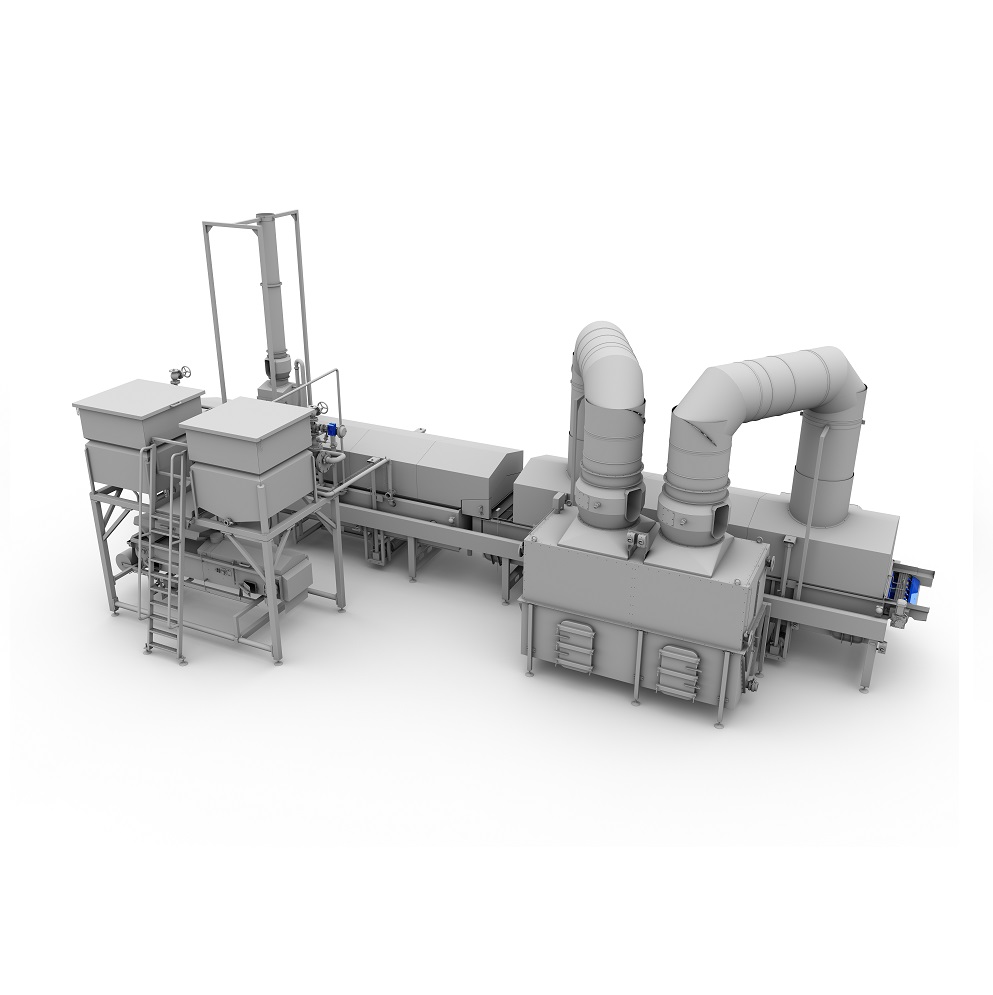

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

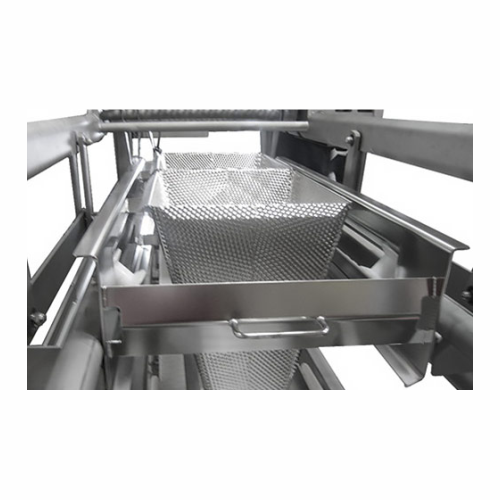

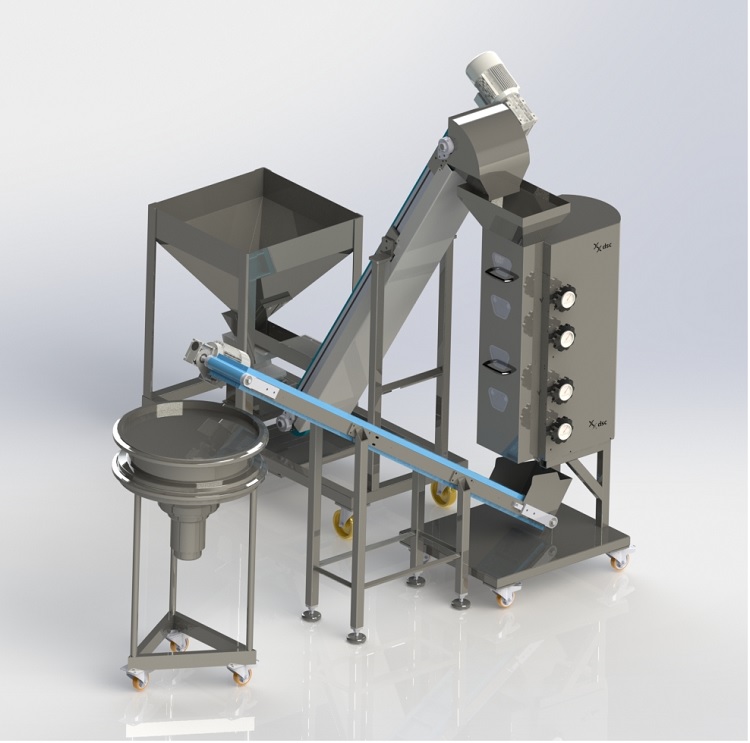

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

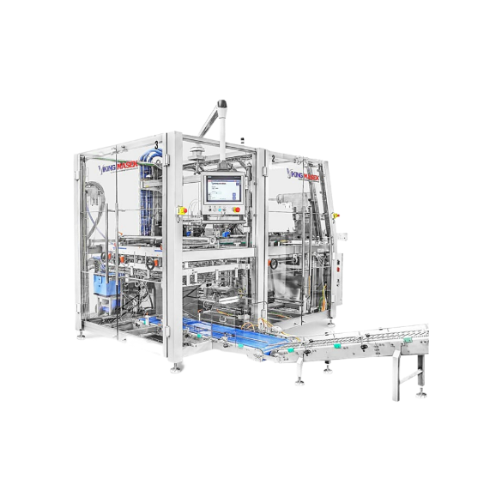

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

Professional grater for parmesan and hard cheeses

Enhance your processing line with a robust grater designed to efficient...

Nut plasticizer for production cuts

Enhance cutting precision and minimize nut breakages with continuous conditioning, prov...

Almond hulling system for soft and semi-hard shells

Efficiently hull almonds with soft or semi-hard shells to streamline ...

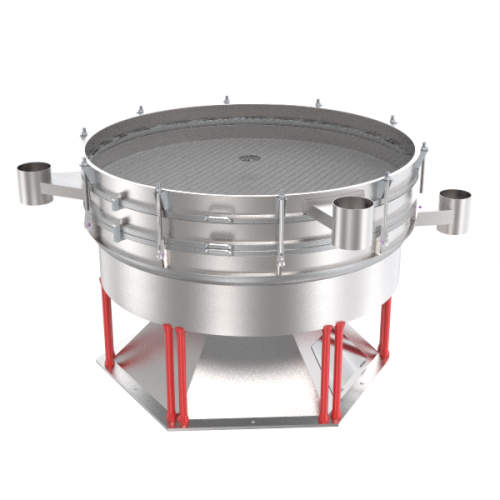

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

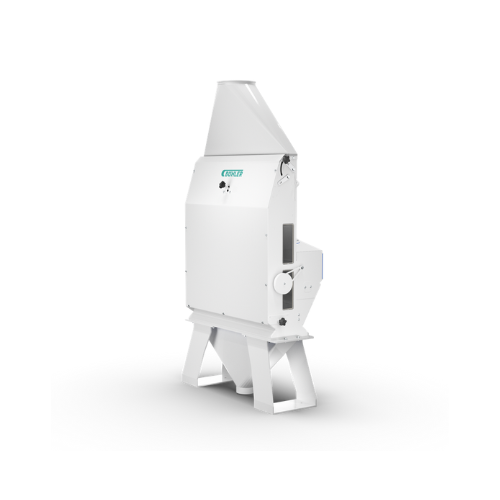

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

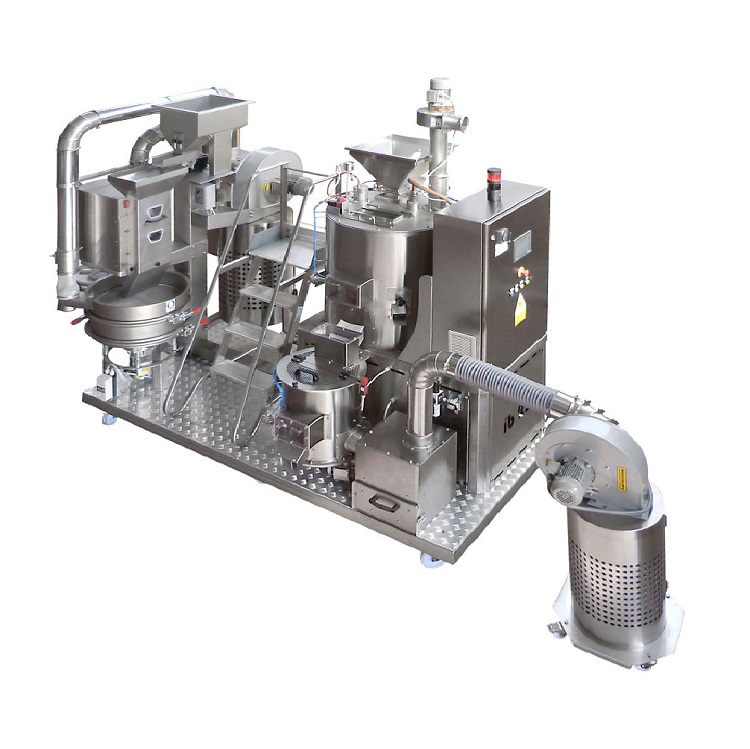

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

Horizontal tray dryer for moisture removal

Ensure consistent product quality in nut and olive processing by efficiently re...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

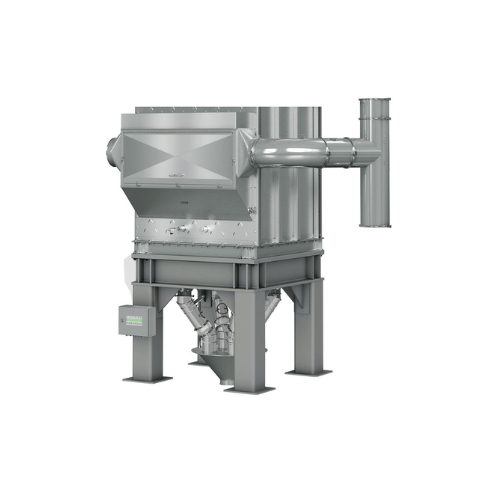

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Almond and apricot kernel blanching solution

Efficiently remove hulls from blanched almonds and apricot kernels to streaml...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

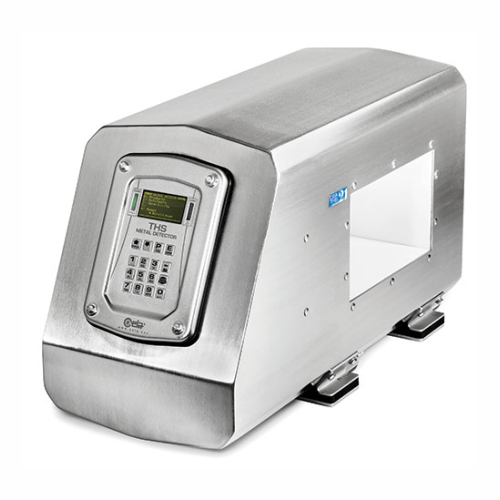

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

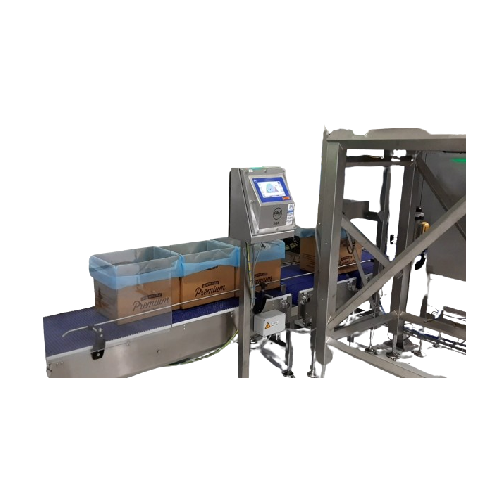

Checkweigher for high-care food environments

For facilities needing precision and hygiene, this high-care checkweigher ens...

High-care food processing combination system with metal detection

Optimize your high-care food environment with a robus...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, thi...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

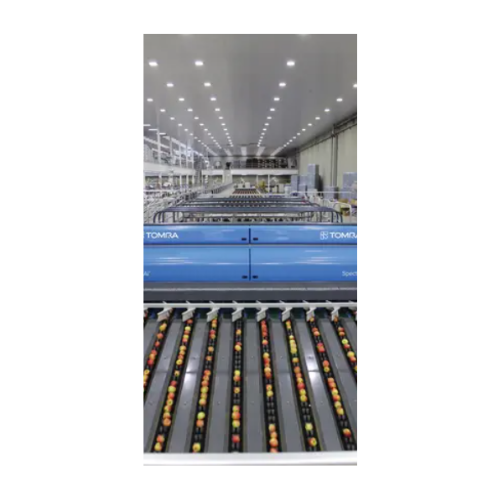

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

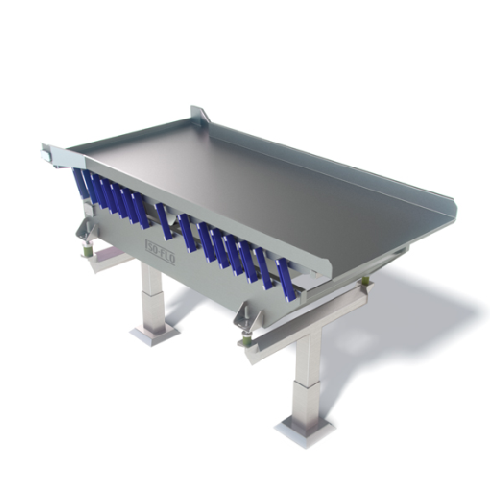

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

Snack food fryer with consistent thermal fluid heating

Achieve uniform frying with precise thermal fluid technology, ensu...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Oil curtain fryer for snack production

Enhance snack quality and shelf life by frying with rapid oil turnover and minimal o...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

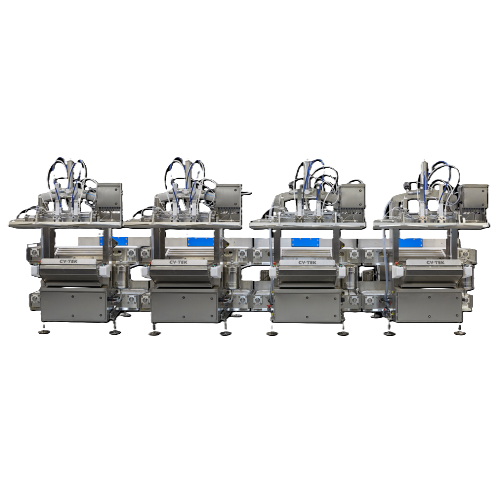

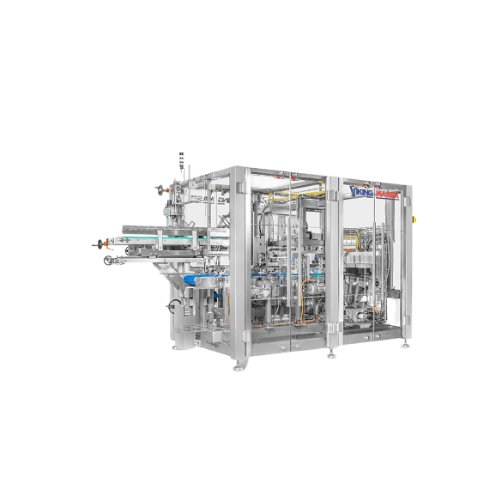

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

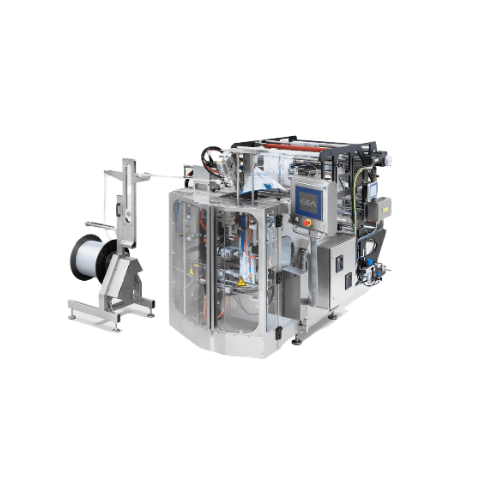

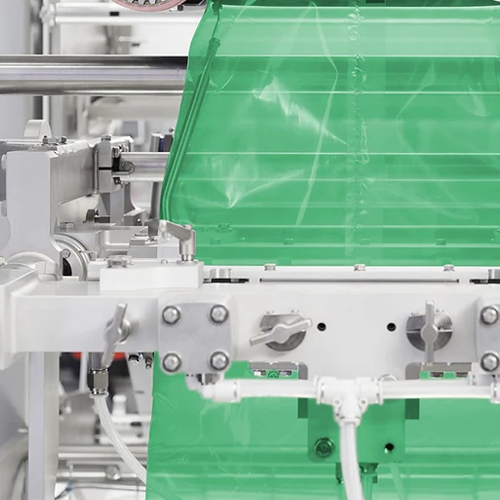

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

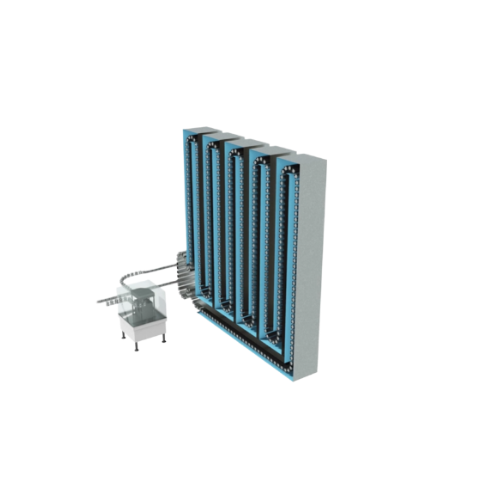

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

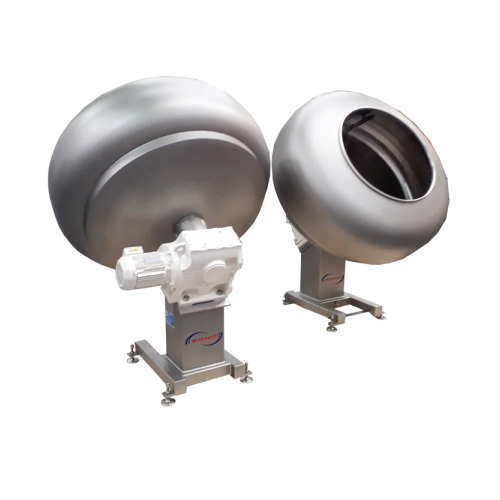

Industrial coating pan for confectionery and pharmaceutical applications

For confectionery and pharmaceutical producers...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Optical sorter for coffee beans

Achieve precise color differentiation and advanced foreign matter detection, optimizing your...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

Modular rotary oven for snack food processing

Optimize flavor infusion and moisture control in snack production with a mod...

Spiral chute for gentle product handling in limited space

Optimize your snack and nut production by minimizing product d...

Citrus brush washer for fruit cleaning

Ensure your produce is impeccably clean with a brush washer designed to efficiently ...

Bi-directional frame scale for industrial weighing

Achieve precise product accumulation and streamlined batch processing ...

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

Semi-automatic tray sealer for ready meals

Achieve optimal freshness with consistent sealing, maximizing shelf life for va...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Linear conveyor tray sealing

Experience unparalleled flexibility and efficiency in tray sealing with high-speed integration,...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

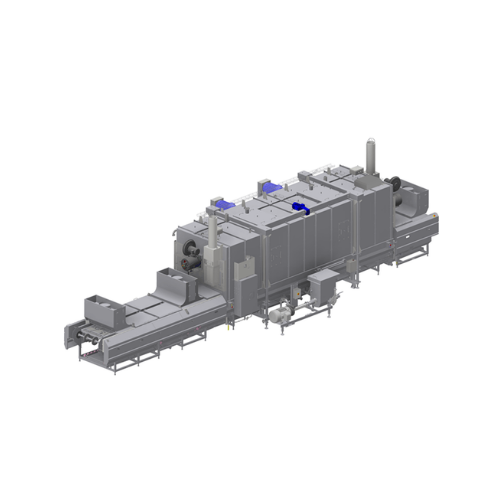

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

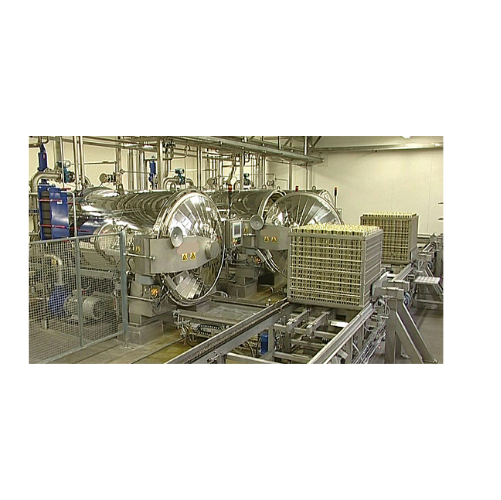

Pilot rotary retorts for laboratory sterilization

Optimize your prototype testing with precision thermal simulations to p...

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

Industrial retort for food sterilization

Achieve uniform sterilization and cooling in your batch production processes while...

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation fro...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Brush bed system for fresh produce cleaning and waxing

Optimize your fresh produce processing with this advanced brush sy...

Heated flooder for sanitation in fresh produce processing

Optimize your fresh produce processing with a heated flooder, ...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

Smart dryer system for fresh produce

Optimize your fresh produce drying process while ensuring consistent quality and effic...

Self-stacking belt for industrial freezers

Enhance your production line with advanced self-stacking belt technology, desig...

Compact spiral freezer for food processing

Enhance your production efficiency and hygiene standards with a compact, self-s...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Impingement freezer for thin product freezing

Optimize your freezing process with advanced airflow, ensuring quick and uni...

Economy breading applicator for granular coatings

Achieve consistent coating uniformity with a conveyorized breading syst...

Flour and crumb feeders for breading and pre-dusting processes

Optimize your breading and pre-dusting operations with ad...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

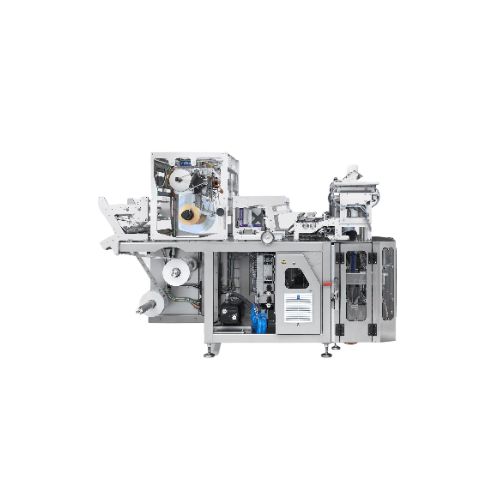

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Wet almond peeling machine for nut processing

Enhance your nut processing efficiency by achieving up to 98% peeling rate w...

Automatic onion peeling system

Efficiently peel and prepare onions with precision using this high-speed, fully automatic sys...

Industrial almond slicer for nut processing

Achieve precise nut slices with adjustable thickness, perfect for enhancing pa...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Almond sheller

Streamline your nut processing operations with a high-efficiency shelling machine designed for precision cracki...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Fully automatic electric heating frying system

Streamline your frying operations with a versatile system that not only sav...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial nut crusher for dried fruit processing

Optimize your nut and dried fruit processing by reducing them to precis...

Chocolate products aligner for chocoform extruder

Enhance your chocolate production line efficiency with a precision alig...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Cluster production system for chocolate with nut inclusions

Efficiently create customized chocolate clusters with precis...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Sanitary modular bulk silos for efficient storage

Maximize your storage capacity and streamline assembly with a modular s...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

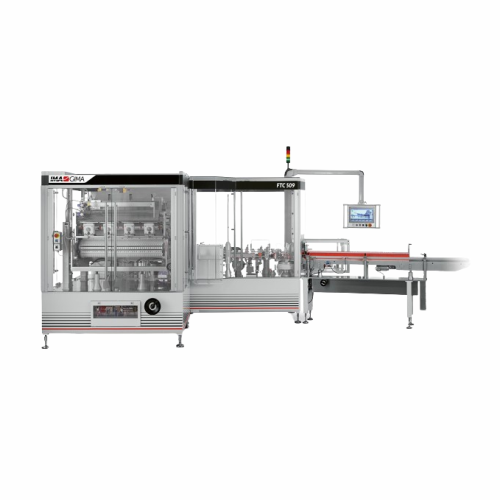

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...