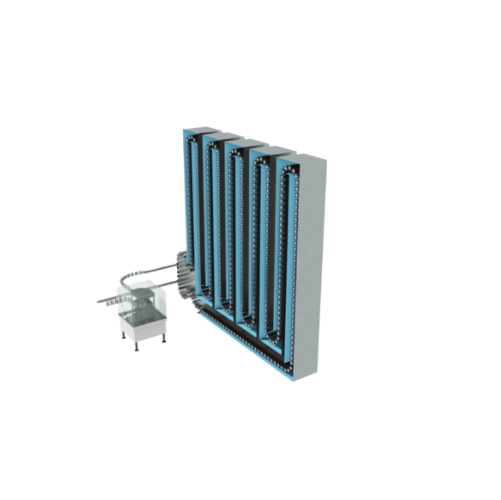

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous sterilization solution, perfect for high-throughput processing of a wide range of container types and food products, while ensuring consistent product quality and energy efficiency.

Processes and Sterilizes Diverse Food and Beverage Products

The Hydromatic® Hydrostatic Sterilizer from JBT is designed to meet the rigorous demands of food processors and beverage manufacturers. It offers continuous processing with high throughput for a wide range of food and beverage products, including dairy, pet food, and ready meals. Operating on a fully automated system, it ensures minimal operator involvement while maintaining uniform process conditions for optimal product quality. Notably, this equipment allows for adjustable time, temperature, and pressure, providing high process flexibility. Its multi-stage sterilizing process accommodates various packaging types such as metal, glass, and plastics. The sterilizer is engineered for energy efficiency and reduced maintenance costs, featuring a compact design that conserves floor space. Compliant with industry standards, it’s ideal for maintaining product integrity and safety while enhancing operational efficiency.

Benefits

- Enhances production efficiency by processing a diverse range of package types continuously.

- Minimizes operational costs through energy-efficient design and reduced maintenance needs.

- Ensures high product quality with consistent and uniform sterilization conditions.

- Adapts to varying production needs with adjustable processing parameters.

- Conserves factory floor space with its compact and integrated design.

- Applications

- Beverages, Seafood, Ready meals, Long-life dairy and soy drinks, Pet food, Condensed soup, Meat, Dairy alternatives, Moist pet food, Fruits, Fish, Nuts, Vegetables, Poultry, Baby food, Low-acid drinks, Dairy, Juices

- End products

- Beef stew, Infant formula, Sports drinks, Chicken breast fillets, Mushroom cream soup, Uht milk, Orange juice, Almond milk, Canned tuna, Plastic-wrapped lasagna, Iced coffee, Beef jerky, Roasted almonds, Canned peaches, Sardines in oil, Canned green beans, Smoothie drinks in bottles, Poultry pate, Spinach bites, Canned dog food

- Steps before

- Preparation, Filling, Food Safety, Fruit, Vegetable Processing

- Steps after

- In-Container Sterilization, Packing, Labeling, Storage, Distribution

- Input ingredients

- condensed soups, moist pet food, long-life dairy drinks, soy drinks, vegetables, ready-to-serve meals, fish, meat, low-acid drinks in cans, glass containers, HDPE containers, semi-rigid containers

- Output ingredients

- sterilized condensed soups, sterilized moist pet food, sterilized long-life dairy drinks, sterilized soy drinks, sterilized vegetables, pasteurized ready-to-serve meals, sterilized fish, sterilized meat, sterilized low-acid drinks, sterilized and pasteurized beverages in metal containers, glass containers, HDPE containers, semi-rigid containers

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Process Type

- Continuous

- Capacity

- High volume

- Container Type

- Metal, Glass, Rigid/Semi-rigid Plastic, Pouches

- Process Flexibility

- Time, Temperature, Pressure Adjustable

- Automation

- Fully Automated

- Maintenance Cost

- Low

- Floor Space Usage

- Minimal

- Sterilization Time

- 10-20 minutes (Hydromatic ZCS)

- Handling

- Proven Reliability

- Agitation Option

- Mild Agitation

- Automation level

- PLC / SCADA / Fully automated

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cooling and heating integration

- Continuous cooling and heating phases

- Flexibility

- Adjustable time, temperature, and pressure conditions

- Process capability

- High volume process capabilities for various container types

- Energy efficiency

- Highly efficient energy usage

- In-plant logistics

- Easy, continuous integration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Metal, Glass, Rigid and Semi-Rigid Plastic, Pouches

- Product agitation requirement

- Yes/No

- Footprint

- Minimal

- Package types

- Metal, glass, plastic, pouches

- Discharge method

- Fully automated

- Agitation type

- Mild end-over-end

- Package dimensions

- Various

- Compact footprint

- Minimal floor space usage

- Control panel type

- Fully automated handling

- Process flexibility

- Adjusting time, temperature, and pressure conditions

- Integration possibilities

- Easy, continuous in-plant logistics