Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling solutions, designed to seamlessly integrate into your production line and enhance operational efficiency across a wide range of end products.

Fills, Weighs, Measures, and Dispenses Products

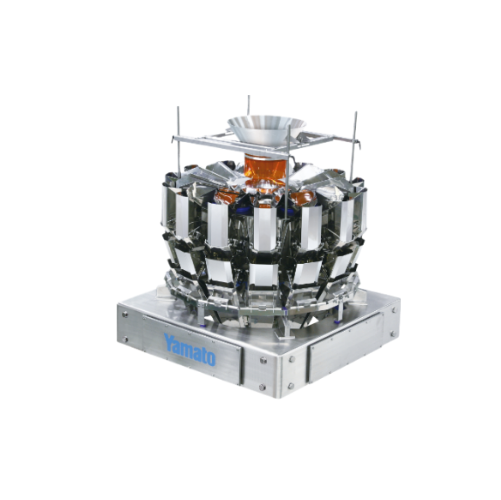

Viking Masek’s Integrated Product Filling and Weighing System combines versatility and precision to enhance your production line. This system uses advanced multi-head scales, auger fillers, and liquid fillers to ensure accurate weighing, measuring, and dispensing across a wide range of products, from granola and cold brew coffee concentrate to surgical gloves and vitamin capsules.

Designed for continuous high-speed automated operations, it seamlessly integrates into existing production lines, ensuring efficient upstream and downstream transitions. With its PLC control system, remote monitoring capability, and reduced energy consumption through optimized motor controls, this equipment offers increased efficiency and reduced operational costs.

Constructed from durable materials suitable for food, beverage, and medical industries, the system adheres to strict sanitary and compliance standards, making it an indispensable asset for contract packagers and product manufacturers. Customization options are available to meet specific production requirements, supported by Viking Masek’s engineering expertise and reliable maintenance services.

Benefits

- Ensures consistent product quality with precise filling and weighing accuracy.

- Increases operational efficiency through seamless integration into existing lines.

- Reduces energy costs with optimized motor control systems.

- Complies with industry standards for food and medical products.

- Offers customizable configurations to meet specific production needs.

- Applications

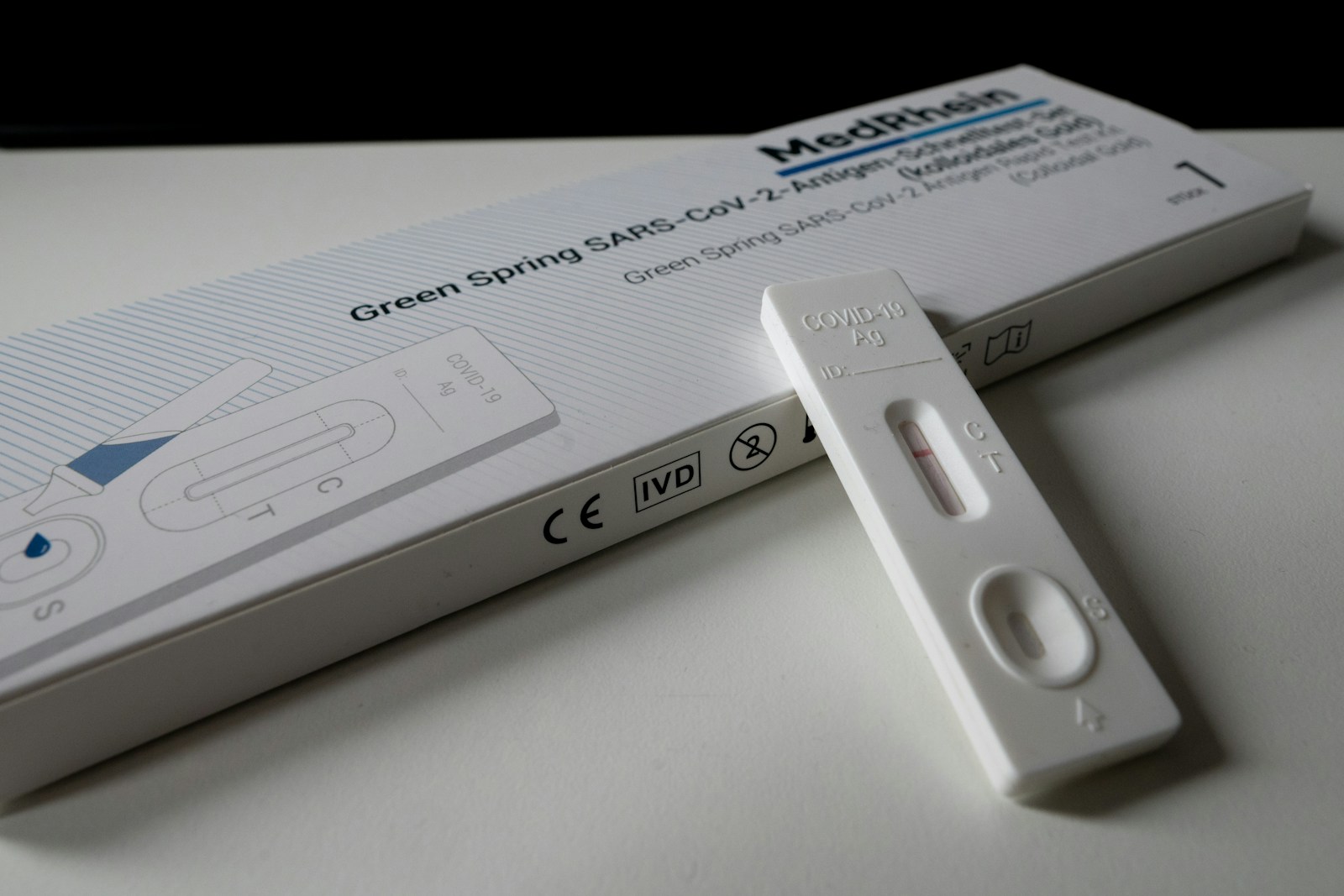

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Iqf (individual quick frozen), Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Powders

- End products

- Spaghetti, Bottled water, Thc gummies, Potato chips, Sliced carrots, Pregnancy test kits, Popcorn, Goat cheese, Fish oil pills, Fruit juice, Whole wheat bread, Kidney beans, Salmon fillets, Chicken breasts, Roasted coffee beans, Dried cannabis flower, Iqf berries, Protein powders, Fresh apples, Cornflakes, Organic peanut butter, Sugar, Cold brew coffee concentrate, Granola, Dog treats, Cat kibble, Cashews, Almonds, Surgical gloves, Muesli base flakes, Gummy bears, Blood glucose meters, Iqf vegetables, Flour, Chocolate bars, Arborio rice, Vitamin capsules

- Steps before

- Sorting, Weighing, Mixing

- Steps after

- Packing, Labeling, Sealing

- Input ingredients

- granular products, powder products, liquid products, solid products

- Output ingredients

- consistent weight packages, consistent volume packages

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Filling accuracy

- ±0.1 g to ±5 g

- Automation

- PLC-controlled

- Filling method

- Volumetric / Gravimetric

- Capacity

- Varies

- Filling speed

- Variable, depending on product

- Filling volume

- Adjustable, depending on filling type

- Automation level

- PLC / Fully Automated

- Changeover time

- Quick Changeover

- Batch vs. continuous operation

- Batch / Inline

- Cleaning method

- Manual / CIP compatible

- Energy efficiency

- Optimized for Low Energy Consumption

- Air incorporation control

- Available

- Cleanability

- High

- Biological compatibility

- Food grade

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Abrasion resistance

- Yes

- Foaming

- High / Low

- Viscosity

- Thin / Thick / Free-flowing

- Container size

- Small / Medium / Large

- Container shape

- Round / Square / Irregular

- Abrasiveness

- Yes / No

- Heat sensitivity

- Yes / No

- Product Type

- Solid / Liquid / Granular

- Product Density

- Low / Medium / High

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Seamless integration with packaging machinery

- Scalability

- Single to multi-head configurations

- Custom filling heads

- Liquid / granular / powder fillers

- Modular design

- Adaptable to various packaging lines