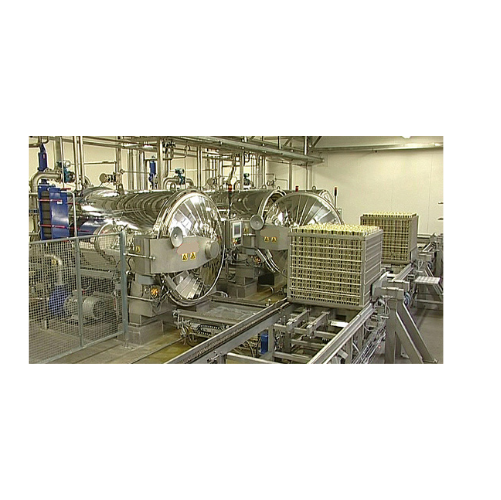

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation from loading to packaging, ensuring precision and consistency for a variety of food and beverage products.

Sterilizes and Automates Batch Processing

The Automated Batch Retort Systems (ABRS) from JBT is designed to revolutionize sterilization and packaging for industries ranging from food and beverage to pet food. With its capability to seamlessly transport baskets through sterilization retorts, ABRS ensures product integrity and compliance with safety standards. It accommodates a variety of containers, including rigid, semi-rigid, and flexible options, making it versatile for applications like canned peaches, apple juice, roasted almonds, and microwavable lasagna.

Configured for both semi-automatic and fully automatic operations, ABRS integrates into your production line with ease, employing robotic systems for flexible containers and a fixed or shuttle conveyor for transport. Reducing labor costs and enhancing productivity, it offers precise automation control for consistent batch processing. The system’s construction can include stainless steel components for enhanced corrosion resistance, making it suitable for high-acidity products. Additionally, JBT provides engineering support for tailored automation needs, ensuring the system aligns with your specific operational requirements.

Benefits

- Enhances operational efficiency by automating batch processing in sterilization.

- Reduces manpower with automated transportation and packaging systems.

- Versatile handling of various container types, minimizing equipment adjustments.

- Ensures product safety with consistent and compliant sterilization processes.

- Customizable design supports specific production requirements and scalability.

- Applications

- Beverages, Soups, Sauces, Seafood, Ready meals, Pet food, Meat, Fruits, Oils, Nuts, Dressings, Poultry, Seasonings, Baby food, Juices

- End products

- Olive oil, Pureed baby carrots, Ranch dressing, Tomato soup, Black pepper seasoning, Roasted almonds, Apple juice, Canned peaches, Frozen fish fillets, Canned chicken breast, Microwavable lasagna, Marinara sauce, Dry dog kibble, Carbonated soft drinks

- Steps before

- Loading, Preparation

- Steps after

- Unloading, Packaging, In-Container Sterilization

- Input ingredients

- rigid containers, semi-rigid containers, flexible containers, bottles, cans, tubs, pouches

- Output ingredients

- sterilized products, packaged goods

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Automation

- Fully Automatic

- Container type

- Rigid / Semi-rigid / Flexible

- Transport method

- Fixed conveyor / Shuttle / Automated Guided Vehicle

- Semi-automatic option

- Available

- Robotic handling

- For flexible containers

- Automation level

- Semi-Automatic / Fully Automatic

- Batch vs. continuous operation

- Batch

- Container handling

- Rigid / Semi-rigid / Flexible

- Transport method

- Fixed conveyor / Shuttle / Automated Guided Vehicle (AGV)

- Sweep-On/Off System

- For rigid containers

- Robotic system

- For flexible containers

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Density/particle size

- 0.5–2.5 g/cm³

- Basket shape

- Rectangular/Circular

- Basket size

- Customizable

- Feed method

- Conveyor/Automated Guided Vehicle (AGV)

- Discharge method

- Automated

- Container compatibility

- Rigid/Semi-rigid/Flexible

- Control panel type

- Touchscreen/PLC-controlled

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / ERP systems

- Transport method

- Fixed conveyor / Shuttle / Automated Guided Vehicle

- Container handling

- Semi-Automatic / Fully Automatic