Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this digital system, optimizing the quality of end products like dried pasta and egg noodles by automatically regulating water content during preparation, ensuring uniform drying and reducing human error.

Regulates and Monitors Dough Moisture Levels

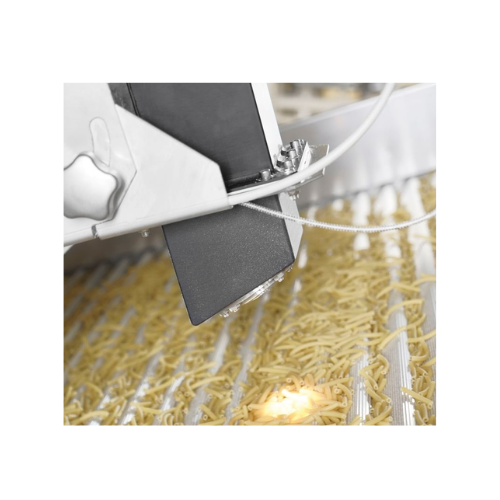

The PastaPro from Bühler Group seamlessly integrates into your food processing line to regulate and monitor moisture levels in dough preparation, ensuring consistent quality for pasta, bakery, and confectionery products. Employing an inline multi-NIR system, it compensates for raw material fluctuations by precisely controlling water addition. Suitable for applications ranging from pasta to baked goods, it supports diverse end products like dried pasta, croissants, and pet food kibbles. Capable of continuous, automated operations, PastaPro optimizes the drying process while reducing waste and manual adjustments. It features robust, dust- and vibration-resistant hardware, with flexible installation options and reliable performance even in harsh environments. The digital dashboard enhances process traceability through real-time quality monitoring and performance benchmarking. With stainless steel options available, PastaPro combines durability with efficient moisture control to elevate your production efficiency, supported by Bühler’s engineering expertise and customization possibilities.

Benefits

- Ensures consistent product quality by maintaining precise moisture control.

- Minimizes manual interventions, reducing labor costs and potential errors.

- Enhances traceability and decision-making with a comprehensive digital dashboard.

- Reduces waste and production costs by optimizing moisture levels and drying processes.

- Offers reliable performance in challenging industrial environments, minimizing maintenance needs.

- Applications

- Snacks, Grain, Chocolate, Dairy, Asian noodles, Pulses, Paddy, Spices, Breakfast cereals, Cocoa, Animal feed, Pasta, Pet food, Nuts, Rice, Dried fruits, Baked goods, Oilseeds, Wheat, Confectionery, Coffee, Vegetables

- End products

- Espresso coffee, Milk chocolate, Cornflakes, Egg noodles, Roasted almonds, Dried pasta, Gummy candies, Potato chips, Red lentils, Croissants, Basmati rice, Dried apricots, Cheddar cheese, Whole wheat flour, Pet kibbles, Canola oil

- Steps before

- Grinding, Mixing, Ingredient Weighing

- Steps after

- Drying, Forming, Packing

- Input ingredients

- raw materials, water, durum wheat, wheat

- Output ingredients

- dough, constant dough moisture, dried pasta

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Automation

- Automatic regulation of dough moisture

- Distance

- Maximum 200 m from sensor to spectrometer

- Design

- Compact and rugged for industrial use

- Moisture Content Control

- Real-time regulation

- Response Time

- No long response times

- Automation level

- Automatic regulation

- Batch vs. continuous operation

- Inline Continuous

- Consistency control

- Real-time moisture regulation

- Integration with existing systems

- Digital dashboard

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Compact and rugged design

- Control panel type

- Digital dashboard

- Discharge method

- Water addition in a controlled manner

- Probes and Camera

- Max distance of 200 m from sensor to spectrometer

- Operational resilience

- Resistant to vibrations and temperature fluctuations

- Control panel type

- Digital dashboard

- Integration possibilities

- Modular installation

- Installation flexibility

- Several predefined positions

- Optical fiber cable distance

- Up to 200 m