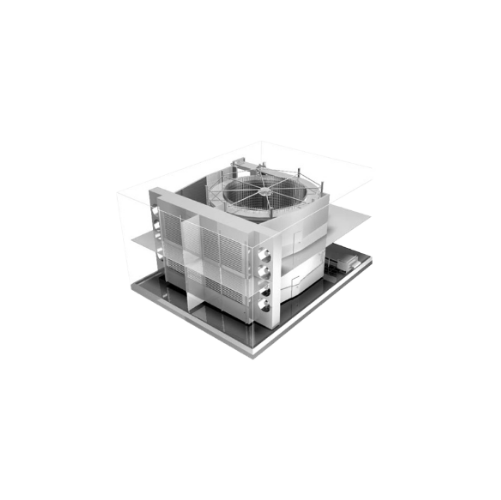

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freezer, designed to handle heavy loads and deliver precise freezing, chilling, and proofing for a variety of products.

Efficiently Freezes and Chills High-Volume Food Products

The Northfield LST® Structure Supported Spiral Freezer by JBT is engineered for robust and efficient freezing solutions across diverse food production needs. Capable of processing over 36,000 lbs. per hour, it is ideal for high-volume freezing of bakery, confectionery, and ready meal products. The structure supports heavy belt loads, handling up to 40 lbs. per linear foot with ease, and offers customizable configurations with options for belt materials, tier pitches, and airflow. Stainless steel construction ensures durability and long service life, while the system integrates seamlessly into continuous production lines, leveraging a patented LVS® Low Volume refrigerant feed system for reduced energy consumption. Standard features like a fully welded enclosure and clean-in-place system simplify maintenance and enhance hygiene, fulfilling stringent industrial requirements.

Benefits

- Increases production efficiency by handling heavy loads and high throughput with minimal downtime.

- Reduces operational costs with lower maintenance requirements due to robust design.

- Enhances energy efficiency with patented LVS® Low Volume refrigerant feed system.

- Simplifies integration into existing lines with customizable configurations and airflows.

- Ensures compliance with hygiene standards through stainless steel construction and clean-in-place system.

- Applications

- Seafood, Ready meals, Pasta, Bread, Bakery, Confectionery, Dairy alternatives, Fruits, Meat, Nuts, Poultry, Dairy

- End products

- Frozen strawberries, Chocolate truffles, Baguettes, Fettuccine, Frozen shrimp, Roasted almonds, Beef patties, Almond milk, Frozen chicken breasts, Croissants, Cheddar cheese, Lasagna

- Steps before

- Flattening, Grinding, Mixing, Injection, Marination, Portioning, Slicing

- Steps after

- Packaging, Weighing, Labeling, Postharvest Processing, Tray Sealing

- Input ingredients

- packaged food products, IQF food products, tall products, heavy products

- Output ingredients

- frozen products, chilled products

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Freezing Capacity

- 36, 000 lbs/hr

- Belt Load Capacity

- 40 lbs/linear ft

- Usable Belt Widths

- 24 to 60 inches

- Belt Speed

- Up to 130 Fpm

- Number of Tiers

- 5 to 35+ tiers

- Rotation

- Clockwise/Counter Clockwise

- Construction Material

- Stainless Steel

- Defrost System

- ADF Air Defrost System

- Evaporator

- High hygiene evaporator

- Refrigerant Feed System

- Patented LVS® Low Volume

- Airflow Options

- Horizontal/Vertical/Double Vertical

- Working Mechanism

- Spiral freezing system

- Integrated Steps

- Freezing, Chilling, Proofing

- CIP Principles

- Clean-in-Place (CIP) system

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- PLC / SCADA

- Energy Efficiency

- High efficiency with low maintenance

- Changeover Time

- Quick installation and start-up

- Defrost System

- Sequential defrost and ADF Air Defrost System

- Machine footprint

- Customizable depending on number of tiers

- Usable Belt Width

- 24 to 60 inches

- Belt Load Capacity

- Up to 40 lbs per linear ft (60kg per linear meter)

- Rotation Direction

- Clockwise (CR) or Counter Clockwise (CCR)

- No. of Tiers

- Five to 35+ tiers

- Material Options for Belt

- Stainless steel or plastic

- Belt Speed

- Up to 130 Feet per minute (Fpm)

- Floor Type

- Fully seam welded stainless steel

- Belt material

- Stainless steel / Plastic

- Belt rotation direction

- Clockwise / Counter Clockwise

- Belt width

- 24 to 60 inches

- Design combinations

- Infinite tier pitch, belt length, width, materials

- Enclosure type

- Fully seam welded stainless

- Heat exchanger size

- Multiple sizes available

- Airflow

- Horizontal, vertical, double vertical

- Layout

- Descending stack, twin stack, duplex/twin belt

- Defrost system

- Sequential, ADF Air Defrost System