Cake Making Equipment

Find innovative production technology for making cakes and connect directly with world-leading specialists

“A party without cake is just a meeting.” America's beloved chef, Julia Child, couldn't have been more right. Nowadays, cakes are a blaze of colors and flavors and it's amazing to think that it only takes a few basic ingredients and steps to make them. Mix fat, flour, eggs, sugar, water and salt to make the batter. After baking and cooling it, let your imagination run wild when it comes to toppings, fillings, and decorations.

Techology picks for producing cakes

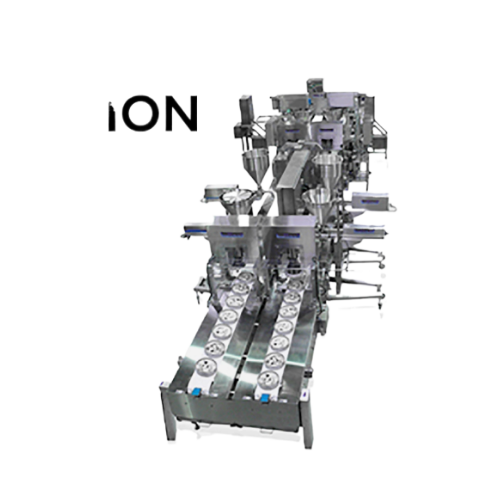

Automated cake icing system

Enhance your cake production efficiency by seamlessly integrating high-speed icing and decoratio...

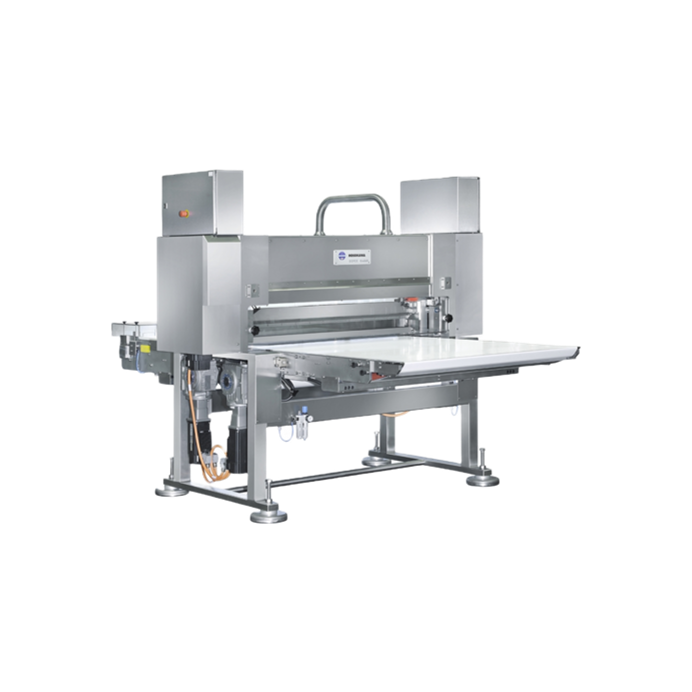

Automatic horizontal cake slicer

Achieve uniform, precise slices with double-blade vibration technology, ensuring each cake ...

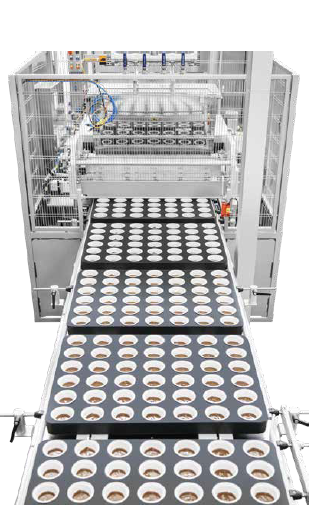

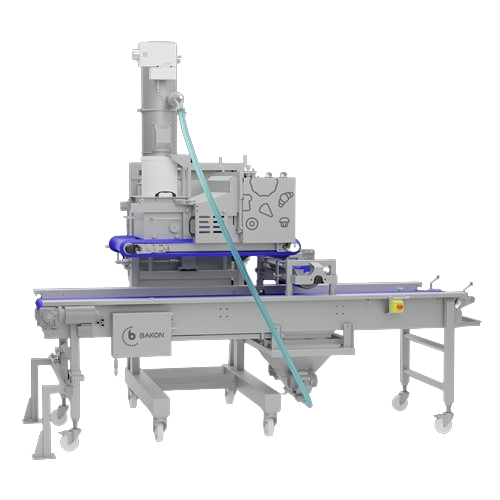

Cake batter and cream depositing machine

Whether you’re making muffins or cupcakes, you need just the right amount of...

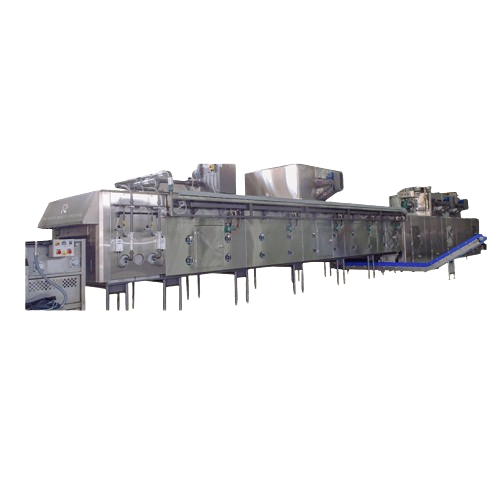

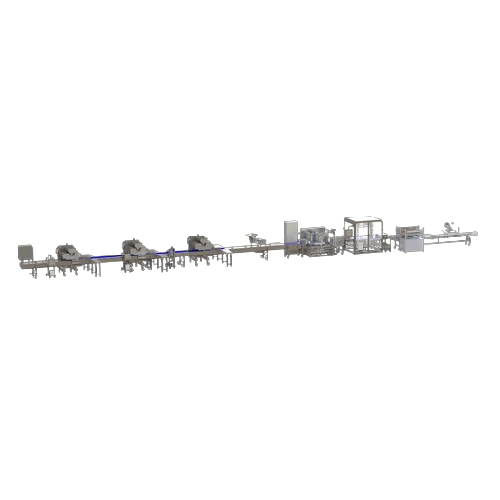

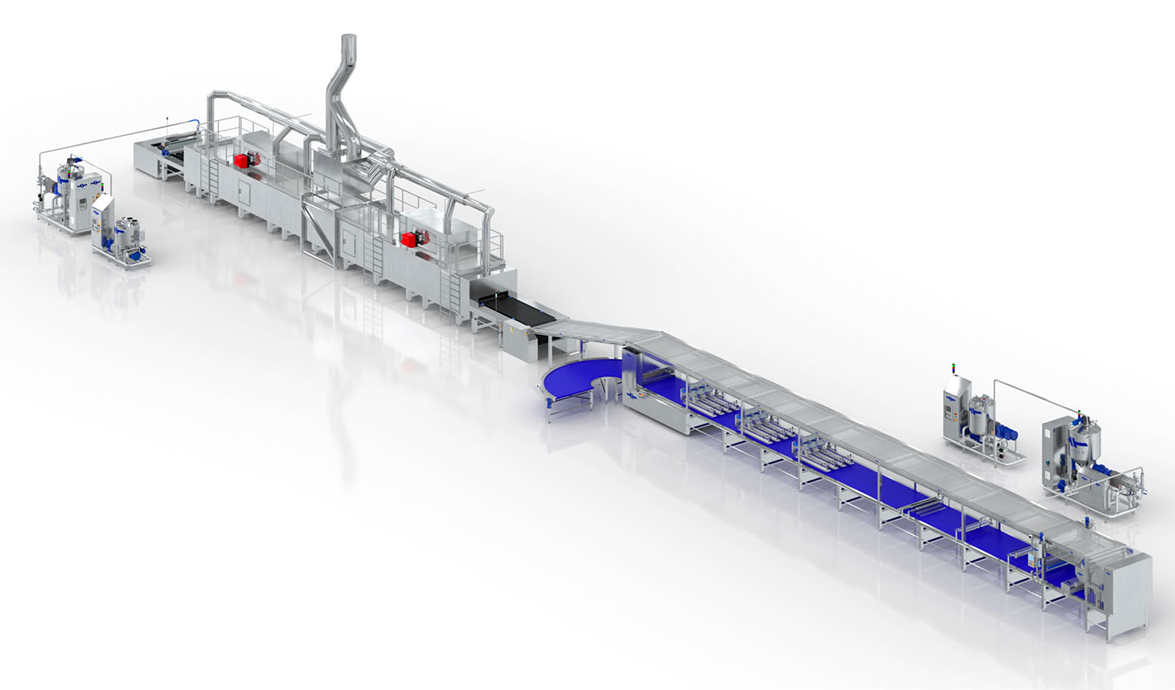

Automated production lines for cakes and cupcakes

Streamline your bakery’s production line with a versatile automat...

Select your cakes process

Tell us about your production challenge

Fat or Foam? - Which F do you prefer for your cake?

Carrot cake, chocolate cake, red velvet cake, rainbow cake…we could go on and on listing the different types of cakes out there. But actually, we can divide them into two main categories depending on the fat content. High-fat or shortened cakes use liquid or solid fats to keep the gluten development low. This way, you can get a tender product and a longer shelf life because the fat slows down the staling process.

Unshortened or foam-style cakes contain little or no fat, but they are very high in sugar. Since there is no fat, you need another ingredient to tenderize them. Here is where the sugar gets in the game. Foam cakes are drier and do not crumble very easily, so they are perfect to be cut in layers or rolled. One of the most famous examples of foam cake is sponge cake.

Give your cake volume by mixing flour, water, eggs, and… air?

Yes, you got it right. To make a cake you need air, the same air you breathe. When you introduce air in a liquid or viscous solution (aeration process), the solution entraps air bubbles forming a foam that gives volume and height to your cake. You can have aeration thanks to the yeast, baking soda or through mixing methods such as whipping and beating. For instance, when whipping egg whites, proteins like ovalbumin and ovomucin are responsible for the volume of the foam. During baking, the heat causes air to expand, resulting in the cake rising.

Taking care of your mixing process – how to avoid holes in your cake

Have you ever seen holes inside a cake? Here, this could be the result of too much air. Overmixing your batter can create more air bubbles and too much air will be incorporated into the mixture. Then, it can weaken also the protein structure while creating a fragile cake that can collapse. In addition, if you overmix your batter, you can create gluten development. Gluten is a network of proteins that when mixed create an elastic structure. This is great in the case of making bread, because we all love bread’s chewy texture, but it is not very great for a cake.

The art of cake decorating

Besides being so delicious, cakes nowadays are also a feast for the eyes. Not only in the artisanal bakeries, but even walking through the aisles of supermarkets you can find various cakes filled with layers of colored icing. To create these colorful layers, after baking, a cake slicer cuts the cake into even layers. If the cake is too dry, a conveyor belt leads each layer under spray nozzles that spray syrup to soften the cake.

Before building the cake and joining all the layers, depositors inject the cream of your choice onto each layer. The final touch is the frosting that is used to cover the cake. The cake is placed on the cake turntable (or rotating tray) while frosting is sprayed or drizzled through a depositor to cover both the top and sides.

Processing steps involved in cakes making

Which cakes technology do you need?

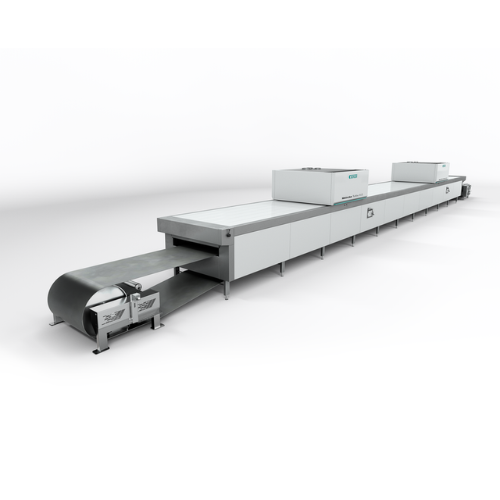

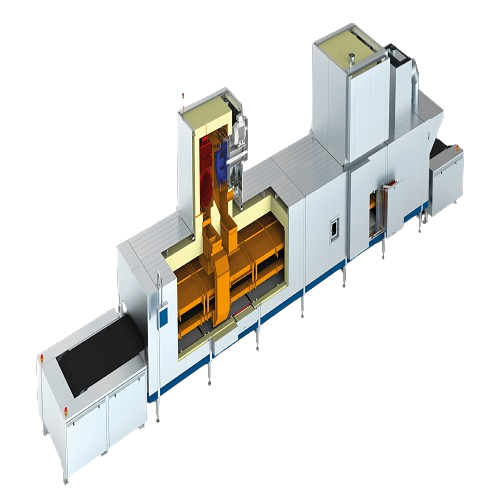

Industrial tunnel ovens for bakery products

Achieve precise control over baking processes with these industrial tunnel ove...

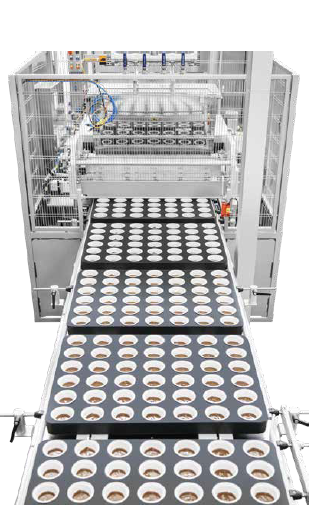

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

Lobe depositors and extruders for filled and decorated cookies

Optimize your bakery production with precision depositing...

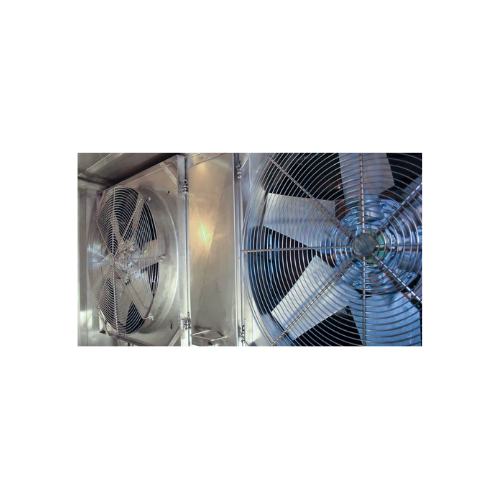

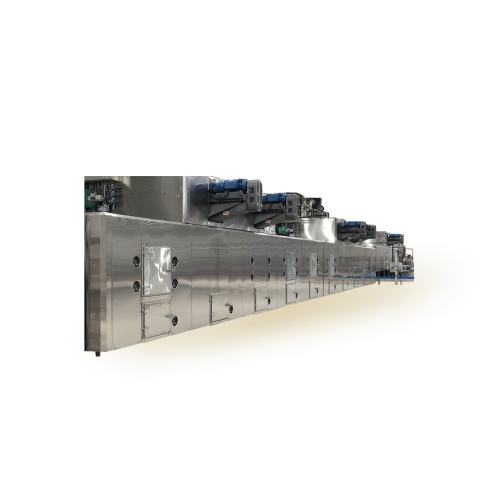

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

Cakes and pastry side injector

Enhance your bakery production with precision side injection technology that efficiently fill...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

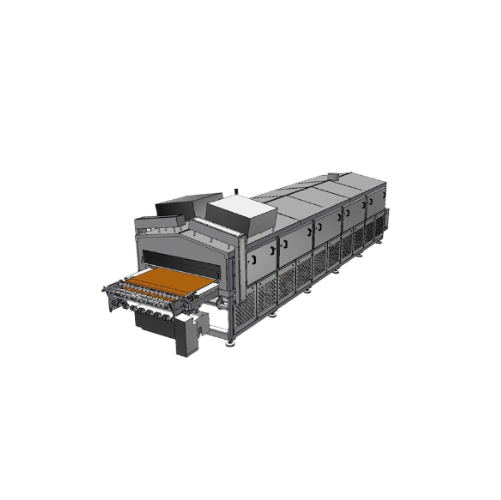

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

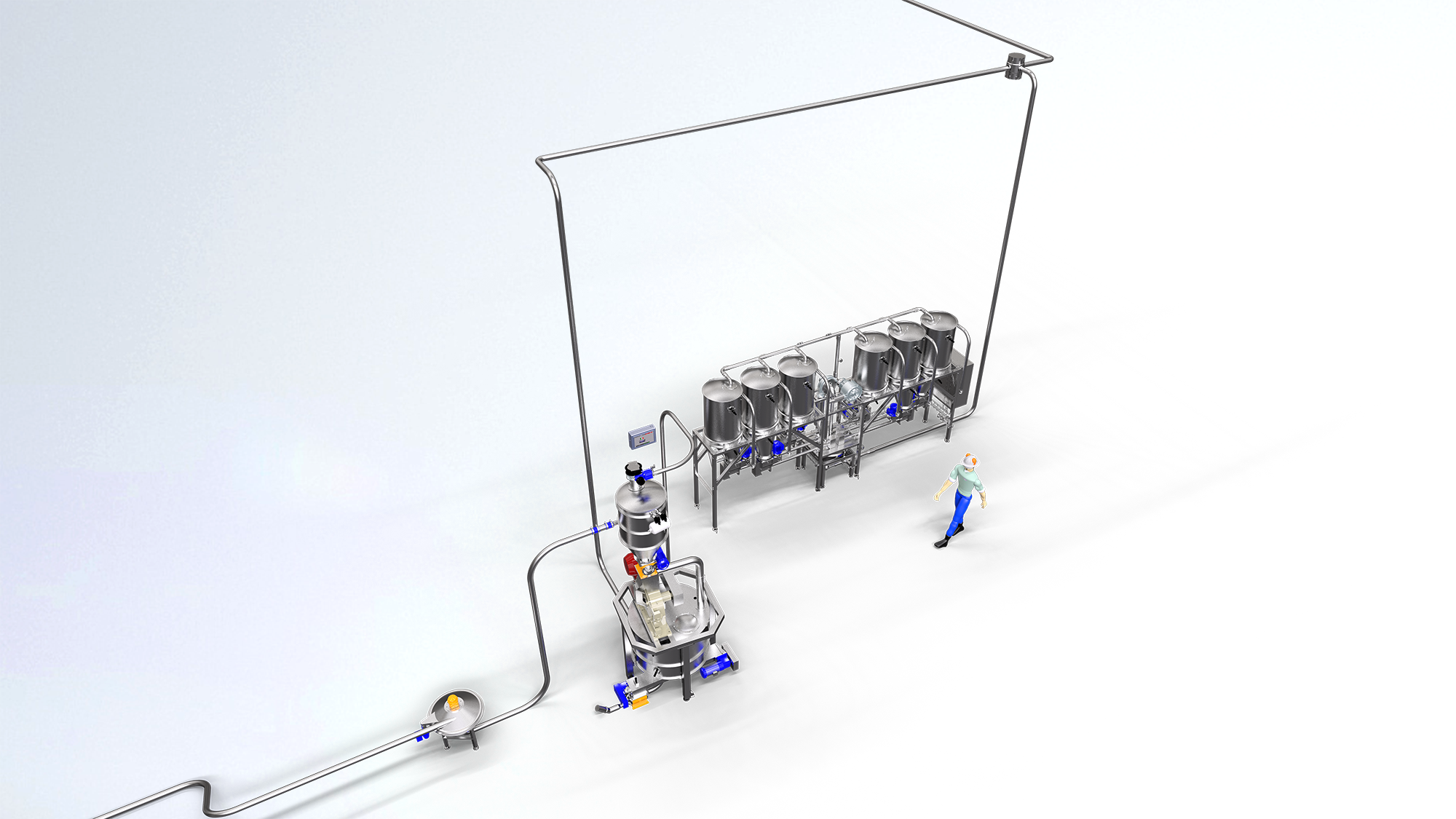

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Dual dosing and topping system for bakery products

Enhance your bakery’s production efficiency with advanced dosing...

Rotating nozzle depositor for pastry production

Optimize your pastry production with precise dosing and shaping capabiliti...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Tabletop bread slicer for various bread types

Achieve precise slicing of breads and cakes with a compact solution that max...

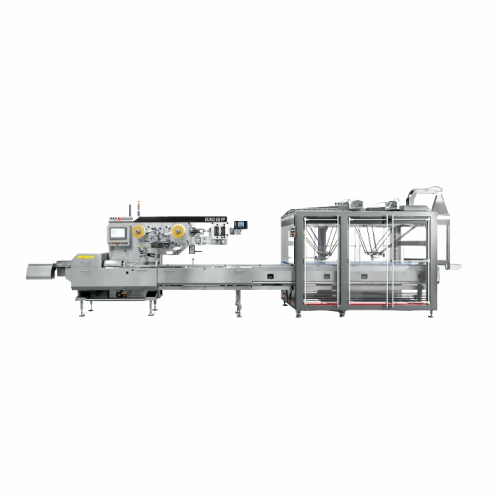

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Planetary mixer for industrial pastry production

Achieve precise dough consistency and enhance baked goods quality with th...

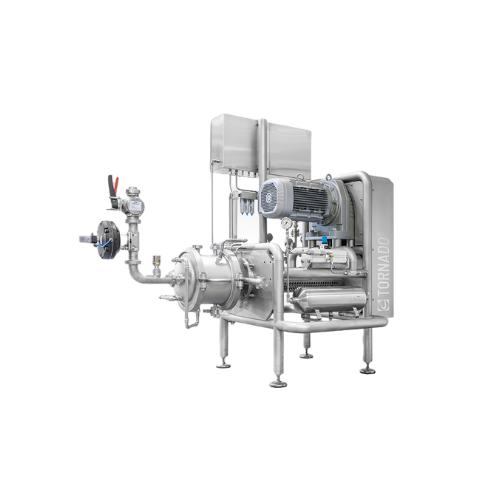

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Industrial manju cake production system

Transform traditional treats into innovative 3D cakes with precise filling and perf...

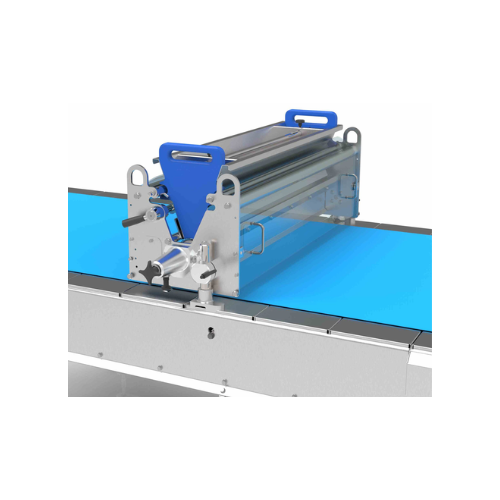

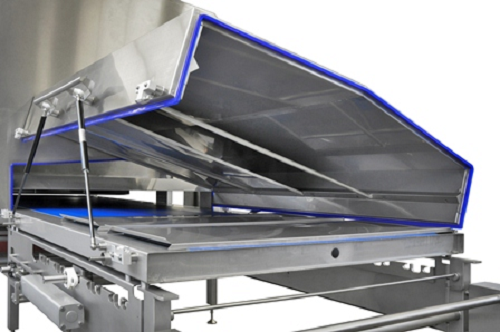

Washover unit for baked goods

Maximize production efficiency with quick-changeover washover units designed for seamless liqu...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Industrial tunnel oven for biscuits and cakes

Achieve uniform baking results with optimized heat transfer and precise mois...

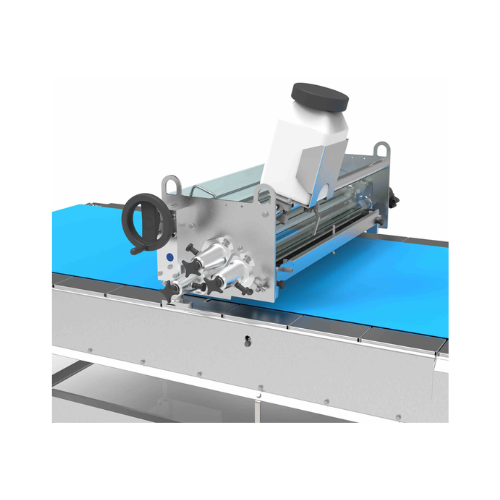

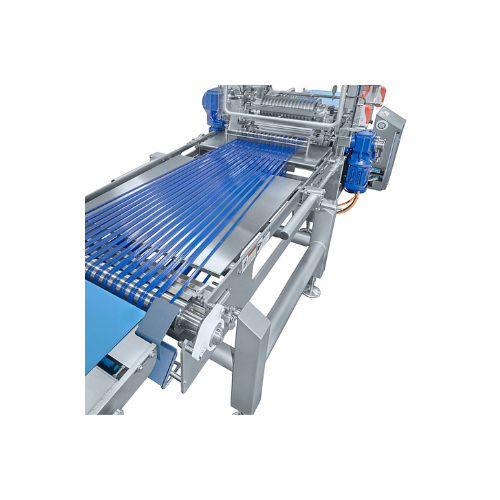

Batter roller sheeter for biscuits and cakes

Achieve consistent batter deposition for your baked goods with this high-spee...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

Hybrid tunnel oven for biscuits and cakes

Enhance production efficiency and product consistency with a versatile oven syst...

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensu...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Ultrasonic slicer for cakes and pastries

Achieve precision cuts and superior presentation with this ultrasonic slicer, desi...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

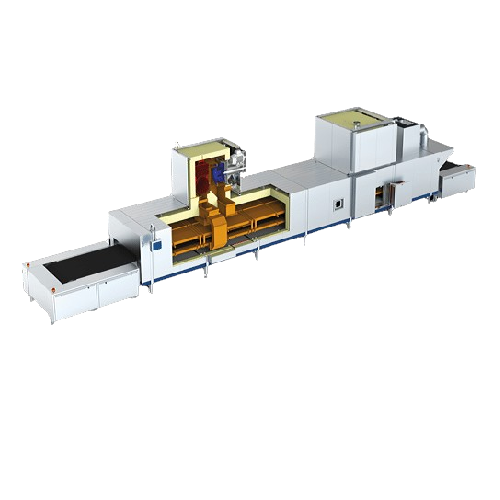

Production line for round and square cakes

Streamline your bakery operations with a modular cake production line designed ...

Ultrasonic cutting line for bakery products

Experience precise slicing and cutting efficiency with our high-capacity ultra...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

3-roll extruder for heavy dough products

Streamline dough processing for consistent, high-quality confections and baked goo...

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

Automatic horizontal cake slicer

Achieve uniform, precise slices with double-blade vibration technology, ensuring each cake ...

Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhanc...

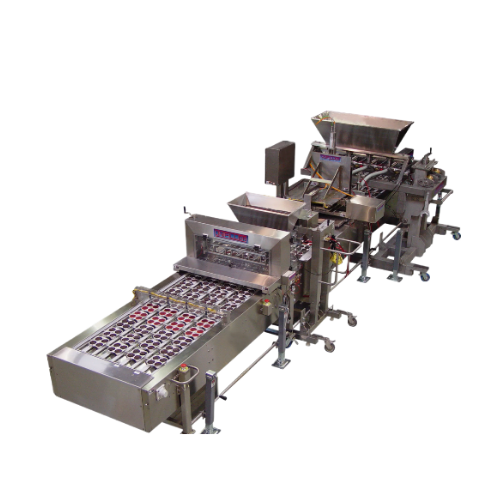

Muffin and cake production line

Enhance your bakery production with a line that meticulously controls every stage, from mixi...

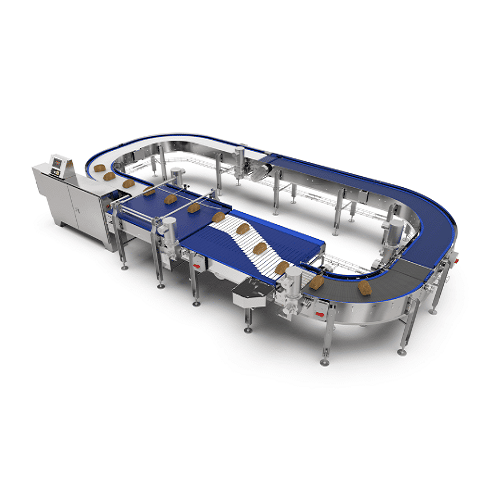

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products ...

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

Industrial cake cutter for round and rectangular cakes

Streamline your cake processing line with high-speed precision cut...

Small-scale depositor and extruder for bakery production

Revolutionize your confectionery and bakery production with a fl...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensurin...

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed f...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Laned product distribution for high-capacity wrappers

Efficiently distribute high-capacity product flow across multiple w...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Process control for baked goods production

Enhance your production line with precise process control designed to optimize ...

Tray cleaning system for bakery applications

Ensure the highest hygiene standards with a system that efficiently cleans an...

Vacuum cooling system for baked goods

Rapidly cool bakery products to extend shelf life and maintain crispness by using adv...

Industrial dough divider for high-capacity production

Optimize your bakery’s throughput with a versatile dough divi...

Industrial vacuum cooling system for bakeries

Achieve rapid cooling of oven-hot baked goods with minimal moisture loss, en...

Modular roll baking system for small bakery items

Optimize your bakery production with a modular roll baking system that ...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

Industrial depositor for bakeries

Enhance your bakery production with precision depositing and filling, designed to handle ...

Industrial servo-based depositor for cake production

Effortlessly manage diverse depositing tasks across high-speed baker...

Sheet cake icing system for bakeries

Enhance your bakery’s efficiency with a high-speed icing system, expertly design...

Portable cake decorating system for shell borders

Streamline your cake decorating with a compact, portable system that re...

Cake and pastry enrobing system

Enhance your bakery production line with seamless enrobing and icing capabilities, ensuring ...

Industrial cake icing system

Enhance cake production efficiency with technology designed for high-speed icing and filling, s...

Cake decorating equipment for bakeries

Optimize your bakery production with equipment designed for precision cake and desse...

Automated cake icing system

Enhance your cake production efficiency by seamlessly integrating high-speed icing and decoratio...

Cake decorating system for bakeries

Streamline your cake production line with a versatile system that handles everything fr...

Icing and decorating system for cake

Enhance your production with precise cake finishing—top, side, and border icing integr...

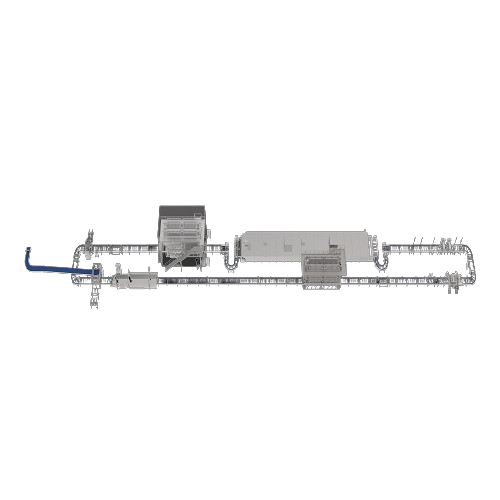

Cheesecake production line

Streamline your cheesecake production with integrated processes for oiling, crumbing, and marblin...

Cake icing and decorating system

Streamline your cake production with this system that adjusts to icing texture changes, ens...

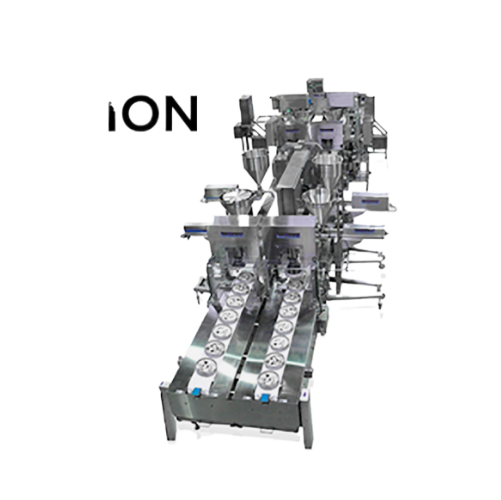

Cupcake production line for automated depositing and decorating

Streamline your cupcake production with high-speed depos...

Automated production lines for cakes and cupcakes

Streamline your bakery’s production line with a versatile automat...

Servo deposition system for industrial cake production

Effortlessly streamline your food production process with precise ...

Automated icing system for cakes

Efficiently layer, fill, and ice various cake types with precision and speed, securing cons...

Cheesecake production system for automated baking

Enhance your dessert production line with a versatile system that autom...

Cupcake production line automation

Streamline your cupcake production with high-speed automation, enabling precise depositi...

Automated cake icing line

Enhance your cake production with precision icing and efficient layering, ensuring each product me...

Horizontal flow wrapper for packaging trays and punnets

Optimize your packaging process with an adaptable flow wrapper, p...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Ultrasonic food cutting

Optimize your production line with precision ultrasonic cutting technology, designed to enhance consi...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Cupcake production line for automated bakery solutions

Streamline your bakery operations with this comprehensive solution...

Commercial delimanjoo and taiyaki custard cake maker

Enhance your pastry production with high-speed, mold-customizable ca...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Ultrasonic food cutter for sticky and fragile foods

Achieve seamless cuts in sticky and fragile foods with ultrasonic pre...

Ultrasonic food cutting equipment

Experience precise and efficient ultrasonic cutting of various food products, optimizing ...

Ultrasonic cake slicing system

Achieve precise, high-speed slicing of delicate and sticky food products with ultrasonic tech...

Sugar and fondant coating solution

Achieve precise, multi-color or single coat applications with thin, uniform layers, seam...

Double sigma arm spiral mixer for bakery applications

Effortlessly tackle high-capacity mixing and kneading with a robust...

Single sigma arm bakery mixer

Streamline complex mixing tasks with precision using a mixer designed for optimal batch contro...

Large capacity confectionary mixer

The foaming process determines the quality of various confectionery products, from marsh...

Compact & pumpable food media mixer

The process of mixing ingredients for confectionery products like marshmallows and meri...

Washdown Cartoner For Frozen Foods

When packing frozen foods into cartons, your packaging system should be cleaned by wash-...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Fully automated rice cake machine

When investing in a larger scale rice cake machine, marketability should be an important ...

Flavouring system for healthy rice cakes and snacks

Being active on the market for healthy popped snacks asks for a flexi...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

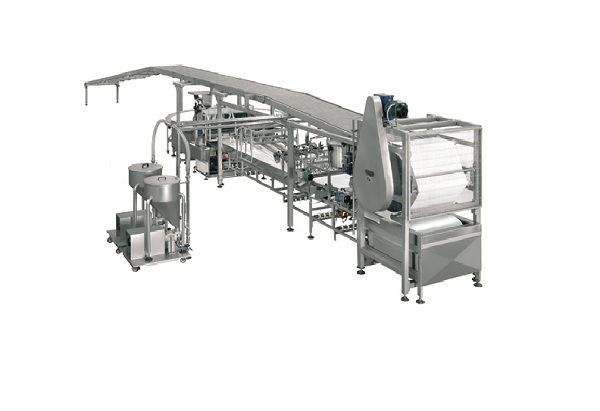

Line for sponge cakes production

Bringing together a wide range of process machinery to develop a production line for sponge...

Sponge cake cooling tunnel

Exposed baked goods can develop bacteria from the circulating air in an area if left in the open ...

Cake batter and cream depositing machine

Whether you’re making muffins or cupcakes, you need just the right amount of...

Sponge cake production line

To produce multiple sponge cake varieties and keep up with the changing industry trends, a produ...

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

High speed decorator for donuts

Donuts quite simply need decorations. The added value through unique and visually appealing ...

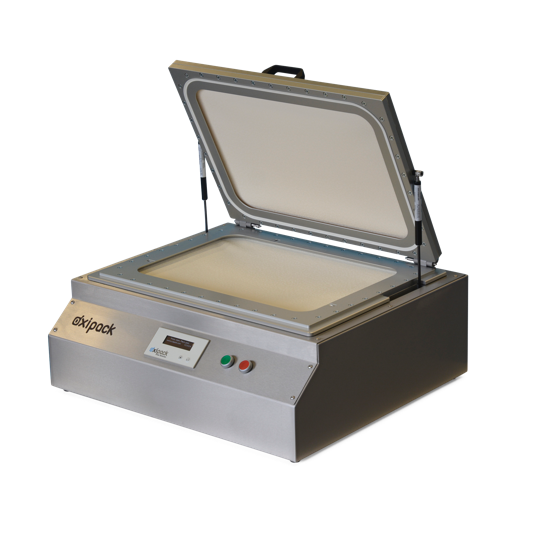

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Inline ultrasonic big scale food cutting machine

In the food industry, where accuracy in the cutting process is desired, u...

Inline ultrasonic food cutting machine

Cutting sticky products in the food sector is not always an easy process. Small scal...

Stand-alone ultrasonic medium scale food cutting machine

Accurately cutting food products in their desired shape, is a pr...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

High speed decorator for filled biscuits

Filling or decorating biscuits was always a difficult task. Sometimes biscuits are...

High speed waffle decorator

In the past, there were not many ways to make waffles or wafers colorful, tasty, and attractive ...

Cake batter dosing machine

High precision machines are essential to ensure a consistent dough mix pours into a mould. The fi...

Stand-alone ultrasonic food cutting machine

For some foods such as cake, pizza, sandwiches or ice cream, the end product i...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

Organic soybean oil press

In traditional soybean oil production, chemical solvents such as hexane are used to facilitate liq...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

Hygienic chocolate cooling tunnel

Quickly cool your product after cooking in preparation for further processing. This is a ...

High capacity decorator

Enhance the appearance of your product by applying final finishing touches and designs. This is a ser...

Ice coating machine

Make consistent use of this high-quality, finish coat with your covered product. This is a coating machin...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

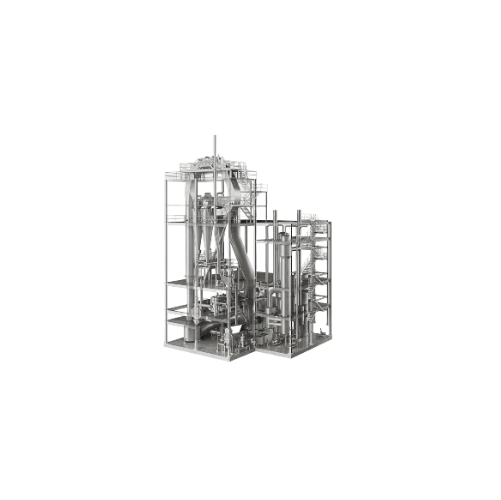

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

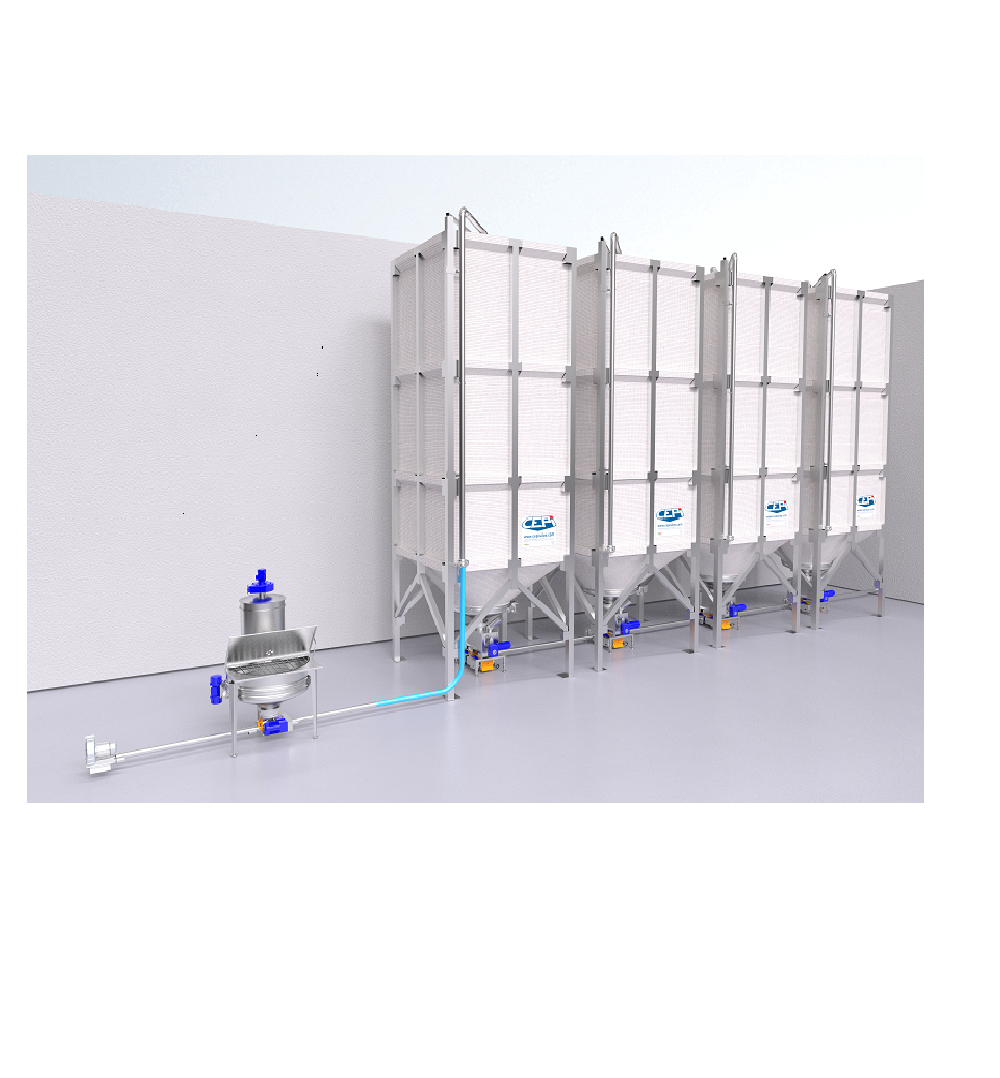

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...

Compact powder pressing machine

Pressed powder products are extremely popular in cosmetics, but their production has challen...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

Cocoa press

After the cocoa beans have been fermented, dried, roasted, and separated from their skins, you obtain a cocoa mass...

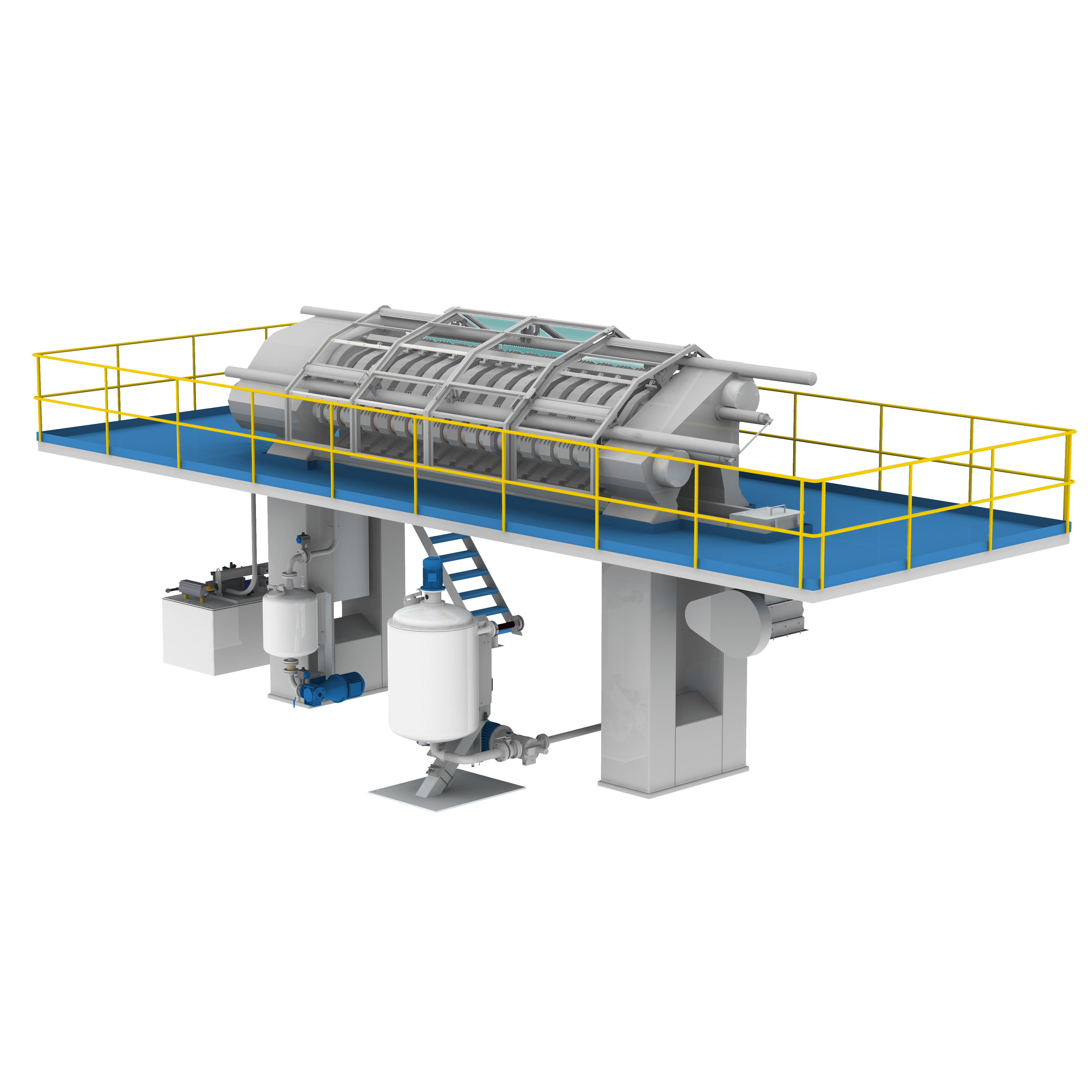

Side bar filter press

Production of dry cakes is required in a variety of industries and robust, low-cost side bar filtration...