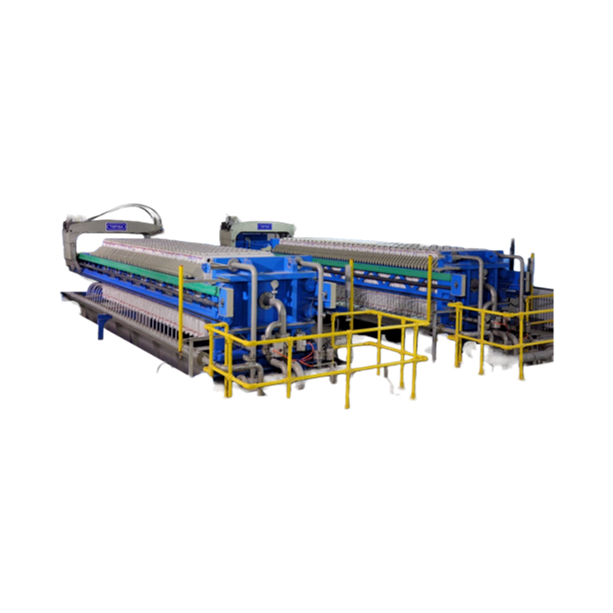

Side bar filter press

Production of dry cakes is required in a variety of industries and robust, low-cost side bar filtration presses are the perfect choice when worry free operation with a lesser degree of automation is required. Whether for water reclamation, waste volume reduction, or primary product manufacturing, plant managers need filtration equipment that is capable, efficient, and reliable and side bar filter press is often an excellent choice.

Low cost, batch production of extremely dry filter cakes

Tefsa has been a leader in the design and manufacture of high quality filtration equipment for over 40 years. The company’s expertise is applied to the smaller scale production of dry cakes from slurries with their line of side bar filter presses. The filter press features a hydraulic ram and filter plates integrated into a rugged frame which includes two horizontal side tie bars to resist the force of the ram as the filter plates are squeezed. The filter plates include handles supported by the side bars and are easily accessed for removal. Standard filtration pressure range is between 6 and 16 bar with specialized units being capable of up to 60 bar. These high pressures generate extremely low moisture content cakes and maximum liquid recovery while requiring minimal use of additives.

Best suited for pilot or smaller scale production applications, the side bar filter press offers a range of available filter areas from 1.7 to 253.5 square meters and is used for batch rather than continuous processes. Tefsa offers models of side bar filter presses that run in manual mode; where the hydraulic ram is actuated by a manual pump and plates and cake changed manually, semi-automatic mode; where the ram is actuated via an electric pump and the plates and cake are changed manually, and fully automatic mode; where the ram, actuated electrically and the plates are transported and cake discharged without operator intervention. All of the models are of a very simple and robust design and are known for extremely long service lives and minimal maintenance requirements.

Benefits

- Highest possible level of cake dryness

- Filter plates include handles and are at a height for easy operator access

- Low power consumption

- Extremely long service life of equipment

- Minimal maintenance requirements