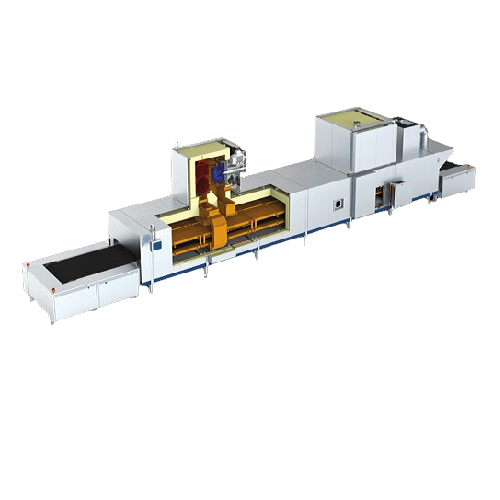

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proofers designed to enhance proofing, baking, and handling efficiency for a wide range of bakery products, ensuring consistent quality and operational flexibility.

Enhances Proofing and Baking Efficiency

The AMF Den Boer Modular Tunnel Ovens and Step Proofers offer an efficient and versatile solution for bakeries and food producers aiming to enhance their proofing and baking operations. Designed with modularity in mind, these systems can be seamlessly integrated into various production lines, accommodating diverse processes such as proofing, baking, cooling, and conveying. The use of high-speed air impingement in the Multibake® I Tunnel Oven ensures uniform baking, ideal for products ranging from sourdough bread to gluten-free pizza crusts. The MB-VITA Tunnel Oven further distinguishes itself with its zero-emission hydrogen fuel option, aligning with sustainability goals by reducing environmental impact and potentially lowering emissions-related costs. These ovens and proofers are designed for continuous operation and offer a turn-key solution, enabling efficient handling from loading to unloading. With configurable options to meet unique production needs, AMF Den Boer systems support high throughput requirements, making them suitable for industries ranging from bakery to confectionery. Optional features like PLC control and remote monitoring facilitate integration into automated processes, while robust construction ensures durability and ease of maintenance. Whether you are producing artisan bread or industrial-grade pizza, these systems provide the engineering support necessary to meet your specific application requirements.

Benefits

- Increases production efficiency with modular design, allowing seamless integration into existing lines.

- Achieves sustainability targets through zero-emission hydrogen fuel options, reducing environmental impact.

- Ensures consistent product quality with uniform heat distribution and high-speed air impingement technology.

- Supports diverse product ranges from artisan breads to gluten-free crusts, meeting varied market demands.

- Reduces operational costs with energy-efficient systems designed for continuous, high-throughput operations.

- Applications

- Buns, Snacks, Flatbreads, Soft breads, Pizza, Pies, Cakes, Rolls, Pastries, Croissants, Artisan bread

- End products

- Puff pastry snacks, Danish pastry, Ciabatta, Pita bread, Gluten-free pizza crust, Hot dog bun, Whole grain flatbread, Sourdough bread, Sicilian pizza, Margherita pizza, Butter croissant, Lemon meringue pie, Naan bread, Pain au chocolat, Cheese cake, Apple pie, French baguette, Brioche bun, Focaccia

- Steps before

- Dough Mixing, Dough Distribution, Dividing, Rounding, Moulding, Intermediate Proofing, Dough Sheeting, Topping

- Steps after

- Cooling, Freezing, Conveying, Packaging, Product Loading, Basket Stacking, Dolly Loading, Palletizing

- Input ingredients

- dough, pizza crust, gluten-free dough, raw bakery products, sweet dough, savory dough

- Output ingredients

- baked pizza, bread, buns, rolls, pies, croissants, pastries, artisanal bread, sheeted pizza, pressed pan pizza

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Oven Type

- Multibake® VITA, Multibake® D, Multibake® H, Multibake® I, Multibake® R, Multibake® E, Multibake® IR, Multibake® HT

- Heating Method

- Hydrogen, Direct, Hybrid, Impingement, Radiation, Electric, Infrared, High Temp

- Operation

- Indirect heating with impinging jets/nozzles

- Air Speed

- High-speed hot air

- Sustainability

- Zero-emission hydrogen

- Automation

- Smart digital services

- Baking Surface

- Stone floor for crisp crust

- Environmental Impact

- Reduced CO2 emissions

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Product types

- Pizza, Bread, Pastry

- Modularity

- Yes

- Footprint

- Customizable

- Assembly Type

- Pre-assembled

- Oven Type

- Tunnel

- Heating Method

- Hydrogen / Direct / Hybrid / Impingement / Radiation / Electric / Infrared / High Temp

- Loader/Unloader Type

- Oven Loader/Unloader

- Proofing Systems

- Step Proofer

- Control panel type

- HMI with touch screen

- Integration possibilities

- SCADA, MES

- Heating options

- Hydrogen, Direct, Hybrid, Impingement, Radiation, Electric, Infrared, High Temp

- Oven loading and unloading

- Automatic systems

- Custom design

- Turn-key concepts