Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhances energy efficiency, reduces emissions, and improves product consistency through advanced monitoring and real-time data analysis.

Optimizes Baking Performance and Reduces Energy Usage

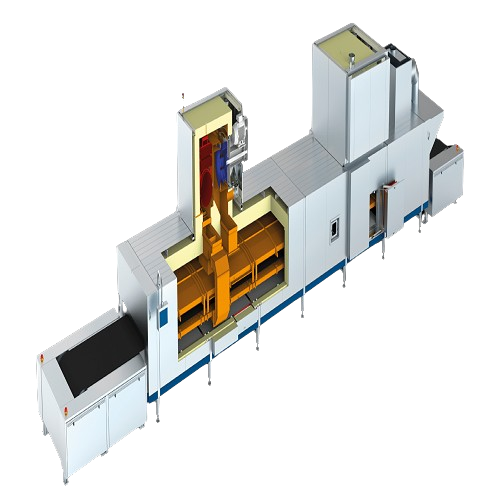

The Sustainable Oven Service (SOS) from AMF Bakery Systems integrates seamlessly into industrial baking operations, offering a transformative solution for monitoring and optimizing tunnel and continuous ovens. Leveraging over a century of baking expertise, this service employs advanced data analytics and artificial intelligence to deliver energy efficiency and consistent product quality. Primarily aimed at bread, buns, rolls, pizza, flatbreads, cakes, pies, and pastries production, the SOS reduces natural gas consumption by up to 20% while maintaining excellent baking conditions. It provides continuous automation and operates at high speeds, integrating smoothly with existing conveyor and baking oven systems. The service is equipped with real-time monitoring capabilities for precise temperature control and vapor exhaust management, ensuring optimal baking settings are maintained. Ideal for food producers and bakery operators in the food production and industrial baking sectors, this service utilizes smart connectivity for enhanced oven performance, offering comprehensive insights and recommendations for process improvements. AMF’s expert assistance includes tailored advice and configurations, ensuring minimal downtime and maximized efficiency throughout the baking process.

Benefits

- Lowers natural gas consumption and CO2 emissions by up to 20%, promoting sustainability.

- Enhances product consistency and quality through precise temperature and vapor control.

- Provides actionable insights for optimal oven operation with real-time data logging and AI.

- Reduces operational costs by minimizing waste and energy usage.

- Supports continuous and high-speed automated baking, boosting productivity and efficiency.

- Applications

- Buns, Bread, Flatbreads, Pizza, Pies, Cakes, Rolls, Pastries, Croissants, Bakery products

- End products

- Steps before

- Mixing, Dough Distribution, Fermentation, Proofing

- Steps after

- Cooling, Freezing, Conveying, Packaging

- Input ingredients

- Output ingredients

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Energy Savings

- Up to 20% natural gas savings

- CO2 Emissions Reduction

- Up to 20% reduction

- Automation

- Data analytics and AI-controlled

- Real-time Data Analysis

- Immediate analysis for efficiency and performance

- Smart Connectivity

- Standard on new AMF Den Boer ovens

- Vapor Exhaust Control

- Balance between exhaust and retainment

- Temperature Distribution

- Optimal temperature distribution and baking curve

- Consistency

- Maintaining a consistent product flow

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Smart connectivity

- Data analytics, AI integration

- Personalized Recommendations

- Expert tailored advice

- Real-time Monitoring

- Continuous data logging

- Temperature Control

- Optimized baking curve

- Vapor Exhaust Control

- Balanced heat retainment

- Steady-State Operation

- Consistent product flow

- Control panel type

- HMI with touchscreen

- Integration possibilities

- Compatible with existing systems

- Data connectivity

- Cloud-based / local server

- Analytics integration

- Artificial Intelligence and data analytics

- Retrofitting capability

- Applicable to non-AMF brands

- Connectivity

- Remote monitoring enabled