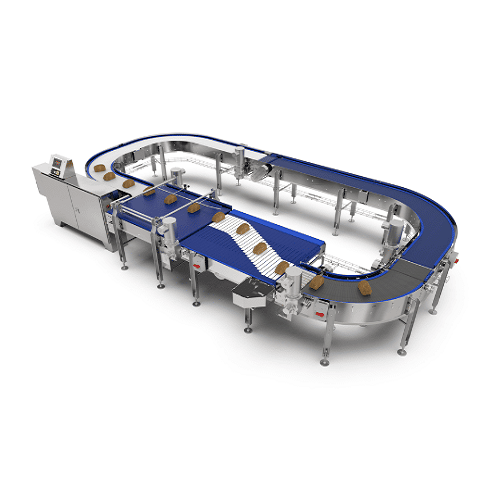

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products with high-speed precision, minimizing sanitation challenges, and boosting efficiency in every stage from raw dough handling to packaged goods.

Diverts and Transfers Bakery Products Efficiently

The EZ Diverter and ARB Product Transfer Systems from AMF Convay are engineered to enhance your bakery’s operational efficiency by ensuring seamless product flow. Designed to manage diverse bakery goods, these systems expertly divert and transfer products like raw dough balls, artisan bread, and packaged snacks between processing lines. The EZ Diverter allows individual products to be directed onto juxtaposed conveyor lines while maintaining a continuous flow, significantly reducing bottlenecks. The ARB system facilitates 90-degree product transfers, minimizing accumulation issues and maximizing throughput.

These solutions are particularly suited for commercial and industrial bakeries, targeting bread, pastries, and pizza production. Capable of handling high-speed and automated operations, they integrate effortlessly into existing lines, ensuring compatibility and enhancing productivity. Available in stainless steel, these systems offer robust corrosion resistance, ideal for bakery environments where hygiene and durability are paramount.

AMF Convay supports customization to meet specific production requirements, with engineering services available for tailored configurations. The equipment is designed for easy cleaning and maintenance, contributing to reduced downtime and prolonged operational life.

Benefits

- Enhances production efficiency by minimizing product bottlenecks and line accumulation.

- Increases throughput with precise product divergence and smooth transfers.

- Reduces labor costs with automated operation and easy integration.

- Designed for easy cleaning, ensuring high hygiene standards with minimal downtime.

- Flexible customization options to fit specific production line needs.

- Applications

- Baked goods, Snacks, Bread, Packaged food, Pizza, Pies, Cakes, Croissants, Pastries, Bakery products, Artisan bread

- End products

- Pressed pan pizzas, Muffins, Packaged rolls, Puff pastries, Raw dough balls, High-speed soft bread, Artisan baguettes, Filled handheld snacks, Sheeted pizzas, Packaged loaves, Packaged snacks, Basket stacks, Sweet savory pies, Danish pastries, Swirl tin bread loaves, Corrugated trays

- Steps before

- Mixing, Dough Distribution, Fermentation, Baking

- Steps after

- Packaging, Slicing, Bagging, Palletizing, Cooling

- Input ingredients

- raw dough balls, pans, lids, baskets, trays, corrugate

- Output ingredients

- baked products, packaged products, basket stacks, pallets

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Automation

- Continuous flow

- Product Transfer

- 90-degree transfer

- Product Handling

- Horizontal distribution

- Diverting Capability

- EZ Diverter

- Individually-divert products

- Transfer Method

- Activated roller belt

- Efficiency

- Maximum efficiency

- Sanitation

- Simple sanitation

- Working Mechanism

- Conveyor System

- Integrated Steps

- Upstream to Downstream Operations

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- PLC / SCADA

- Sanitation Practices

- CIP / Simple Sanitation

- Changeover Time

- Minimal

- Energy Efficiency

- High

- Product Transfer

- Seamless

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Type

- Raw Dough Balls / Baked Products / Packaged Products

- Handling Method

- Intermediate Proofing / Pan and Lid Conveying

- Conveying Type

- Horizontal / Diversion / Perpendicular

- Feed method

- Horizontal distribution

- Discharge method

- EZ Diverter, ARB Product Transfer

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Compatible with existing bakery systems

- Product transfer customization

- Single line / Multiline

- Conveyor line configuration

- Customizable layouts

- Sanitation features

- Easy-clean design