Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance control over baking profiles, allowing seamless adaptation to diverse product requirements on the same line.

Provides Flexible Heat Transfer for Baking and Drying

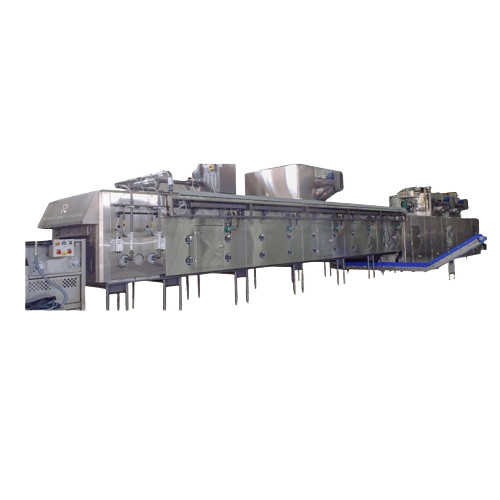

The SMART Oven Zone from Reading Bakery Systems is engineered for industrial bakeries and food processing companies that require adaptable baking solutions. It stands out by offering configurable heat transfer modes, using both radiant and convection heat for optimal product quality. This oven can handle a variety of applications including snacks, pretzels, crackers, cookies, biscuits, granola, and pet food, allowing seamless integration into diverse production lines. It facilitates a flexible baking and drying process with its modular design, permitting rapid adjustments to the baking profile suited for your specific end-products like cheese-flavored crackers or ginger biscuits.

The oven’s capacity is bolstered by its fully automated operation, powered by a feedback-based control system for continuous recipe-based adjustments. It incorporates advanced control systems designed in-house for precision and efficiency, offering real-time monitoring through feedback loops. Available in both gas and electric models, it offers energy efficiency and sustainability, with options to convert existing gas ovens to electric. Constructed under the SafeShield Program, the oven is designed for operator safety, quick sanitation, and food safety compliance. It includes large access doors for easy maintenance, active flame and temperature monitoring, and optional fire suppression systems, ensuring robust safety standards.

Benefits

- Enhances product consistency with configurable heat modes to suit varied baking requirements.

- Increases production flexibility by accommodating multiple product types on the same line.

- Reduces energy costs with options for switching from gas to electric heating.

- Promotes operator safety and sanitation with SafeShield Program standards and easy-to-clean access features.

- Minimizes downtime with quick installation and modular design for rapid baking profile adjustments.

- Applications

- Cookies, Biscuits, Snacks, Pet food, Popped snacks, Potato rings, Chips, Expanded snacks, Crackers, Granola, Pretzels

- End products

- Pretzel sticks, Salted pretzel nuggets, Potato chips, Dry dog kibble, Cheese-flavored crackers, Chocolate chip cookies, Onion-ring-flavored snacks, Popcorn snacks, Almond granola clusters, Tortilla chips, Peanut butter granola bars, Cheese puffs, Caramel popcorn, Fried potato rings, Shortbread biscuits, Ginger biscuits, Oatmeal raisin cookies, Whole grain crackers, Wet cat food

- Steps before

- Mixing, Dough Handling, Dough Forming

- Steps after

- Cooling, Drying, Packing

- Input ingredients

- pretzel dough, snack dough, cracker dough, multi-crisp dough, cookie dough, biscuit dough, granola mix, pet food mix, potato rings, expanded snack materials

- Output ingredients

- baked pretzels, baked snacks, crackers, multi-crisp products, cookies, biscuits, baked granola, baked pet food, stackable chips, popped snacks

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Heat Transfer Modes

- Radiation, Convection, Combined

- Automation

- Feedback-based control system

- Installation

- Factory built sections

- Heat Options

- Gas or electric

- Temperature Monitoring

- Active monitoring

- Safety Features

- Explosion prevention panels

- Sanitation Features

- Large access doors, easy cleaning

- Fire Suppression

- Optional automatic

- Floor Design

- Flat floor in drying chamber

- Heat transfer mode

- Radiant / Convection / Combination

- Automation level

- Automatic monitoring, adjusting

- Baking profile control

- Modular design

- Temperature monitoring

- Active flame, temperature monitoring

- Changeover options

- Gas to electric heat conversion

- Operation type

- Continuous mixing / Conveyor system

- Product type flexibility

- Yes

- Machine Footprint

- Modular design

- Discharge method

- Conveyor system

- Control panel type

- Feedback based control system

- Air circulation and exhaust

- Fully controllable systems

- Access method

- Large access doors

- Oven Zone Configuration

- Flexible heat transfer modes

- Floor design

- Flat floor in drying chamber

- Heat Transfer Mode

- Radiant, Convection, Combination

- Control Flexibility

- Automatic Monitoring and Adjusting

- Energy Source

- Gas or Electric

- Modular Design

- Yes

- Conversion Capability

- Gas to Electric

- Control Systems

- Custom Designed In-House

- Automation Level

- Fully Automated