Cheesecake production system for automated baking

Enhance your dessert production line with a versatile system that automates processes such as pan oiling and marbling, boosting efficiency and consistency in every batch of cheesecakes and confectionery products.

Automates Cheesecake and Dessert Production

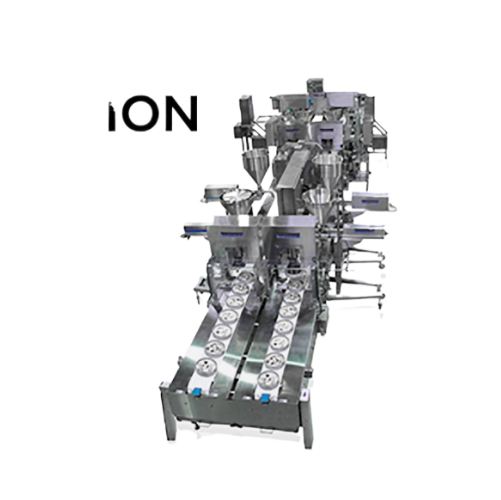

The Cheesecake Production Line Equipment is a streamlined solution designed by Unifiller for bakeries and food processing enterprises seeking to automate the complex task of dessert production. This configuration stands out by integrating multiple processes, including pan oiling, crumb filling, batter and flavor depositing, and marbling, all within a continuous, high-speed production line. Suited for various applications, it efficiently produces a range of products such as cheesecakes, marbled desserts, and crumbed pastries with a throughput of up to 8 cakes per minute.

Equipped with single and multi-piston depositors, spraying machines, and transfer pumps, it ensures precise ingredient distribution and decorative consistency. Utilizing a PLC-controlled system, the equipment allows seamless integration into existing production lines and remote monitoring for enhanced operational oversight. Constructed for an easy washdown, it simplifies cleaning and maintenance, minimizing downtime. Additionally, it offers customization options to match specific production requirements, making it a versatile asset for high-capacity dessert manufacturers.

Benefits

- Increases production efficiency by automating multiple complex processes, reducing manual labor.

- Ensures consistent product quality with precise ingredient depositing and decorating.

- Minimizes cleaning time with easy washdown capabilities, enhancing overall uptime.

- Allows seamless integration into existing lines with PLC-controlled operations.

- Supports diverse dessert customization needs with configurable depositor and decorating options.

- Applications

- Baked goods, Confectionery, Cheesecakes, Desserts, Pastries

- End products

- Marbled desserts, Iced desserts, Whip cream-topped cheesecakes, Crumbed pastries, Jelly-topped cheesecakes, Marbled cheesecakes

- Steps before

- Pan Oiling, Base Crumbing

- Steps after

- Marbling, Drizzling, Jelly Application, Whip Cream Topping

- Input ingredients

- pan oiling, base crumbing, batter, flavor

- Output ingredients

- cheesecake, icing, oil sprayed crust, crumbed base, filled cake, tamped cake, marbled cake, drizzled cake, jelly topped cake, whip cream topped cake

- Market info

- Unifiller Systems is known for manufacturing innovative and precise food processing and bakery equipment, specializing in automated portioning and depositing solutions that enhance efficiency and consistency for bakeries and food production lines globally.

- Speed

- Up to 8 cakes per minute

- Deposit Range

- Configured

- Particle Size

- Configured

- Power

- Varies

- Washdown

- Easy Washdown

- Tools Required

- No tools required

- Working Mechanism

- Pan oiling, base crumbing, batter depositing, marbling

- Integrated Steps

- Oil spraying, crumb fill, tamping, flavor depositing

- Automation Level

- Automated production

- Cleaning Method

- Easy Washdown

- Batch vs. Continuous Operation

- Batch

- Changeover Time

- No tools required

- Speed

- Up to 8 cakes per minute

- Density/particle size

- Configured.

- Machine footprint

- Varies depending on configuration

- Compact footprint

- Yes

- Control panel type

- Integrated/Automated

- Discharge method

- Configured

- Integration possibilities

- Automated Lines, Multi Piston Depositors, Spraying Machines, Transfer Pumps

- Control panel type

- Not specified