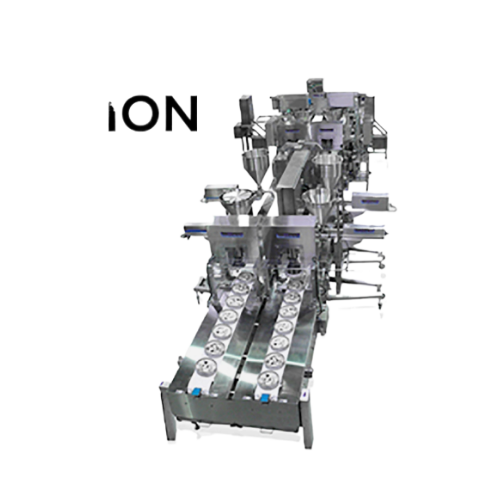

Cheesecake production line

Streamline your cheesecake production with integrated processes for oiling, crumbing, and marbling, ensuring consistency and efficiency from base to topping in every batch.

Automates Cheesecake Production Processes

Unifiller Systems’ Cheesecake Production Line Equipment offers a comprehensive solution for automating cheesecake and dessert manufacturing processes. This system integrates seamlessly into your production line to perform oiling, crumbing, filling, tamping, depositing, and marbling, enhancing efficiency and consistency. Suitable for food, baking, dairy, and confectionery industries, it caters to diverse end products like marbled and whipped cream cheesecakes. Capable of high-speed operations, the equipment is designed for continuous production, handling both solid and liquid components efficiently. Its easy washdown design ensures quick and hygienic cleaning, while tool-free maintenance keeps downtime minimal. The system supports a variety of configurations, including single and multi-piston depositors and spraying machines, providing customizable production solutions tailored to specific operational needs.

Benefits

- Enhances production efficiency by automating key processes like filling and marbling.

- Minimizes labor costs through high-speed, continuous operation.

- Ensures product consistency and quality with precise ingredient depositing.

- Facilitates quick and hygienic cleaning with an easy washdown design.

- Allows for flexible production with customizable configurations for various dessert types.

- Applications

- Sweet goods, Confectionery, Cheesecake, Desserts, Bakery products

- End products

- Cheesecake base, Cream-filled pastries, Whipped cream cheesecake, Crumb crust desserts, Cheesecake with jelly topping, Iced cheesecake, Marbled cheesecake

- Steps before

- Ingredient Preparation, Mixing, Pan Oiling

- Steps after

- Baking, Cooling, Packaging

- Input ingredients

- pan oil, crumb base, batter, flavoring, jelly

- Output ingredients

- cheesecake, icing, sprayed oil, crumb crust, filled cake, tamped cake, marbled cake, drizzled cake, whipped cream topping

- Market info

- Unifiller Systems is known for manufacturing innovative and precise food processing and bakery equipment, specializing in automated portioning and depositing solutions that enhance efficiency and consistency for bakeries and food production lines globally.

- Speed

- Up to 8 cakes per minute

- Deposit Range

- Configured

- Particle Size

- Configured

- Power

- Varies

- Washdown

- Easy Washdown

- Tools Required

- No tools required

- Automation level

- Automated

- Changeover time

- Minimal due to no tools required

- Cleaning method

- Easy Washdown

- Batch vs. continuous operation

- Can be configured for inline processes

- Capacity

- Up to 8 cakes per minute

- Integrated steps

- Pan oiling, base crumbing, batter depositing, marbling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Batter consistency

- Thick / Thin

- Flavor integration

- Marbling / Drizzle

- Production line type

- Automated / Semi-automated

- Spray viscosity

- Low / Medium

- Particle size compatibility

- Configured

- Container size

- Standard cake pan

- Machine footprint

- Varies depending on configuration

- Feed/discharge method

- Automated with no tools required

- Compact design

- Yes

- Configuration options

- Varied to suit specific production needs

- Washdown capability

- Easy Washdown Design

- Control panel type

- Touchscreen / Digital

- Integration possibilities

- Inline / Standalone

- Flavor depositing options

- Custom flavors / Marbling

- Size and configuration

- Configured per client needs

- Deposit range

- Configured

- Particle size handling

- Configured

- Capacity options

- Up to 8 cakes per minute