Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed aeration for confectionery and bakery products, enhancing texture and stability while maintaining consistency across batches.

Aerates and Blends Confectionery Mixtures

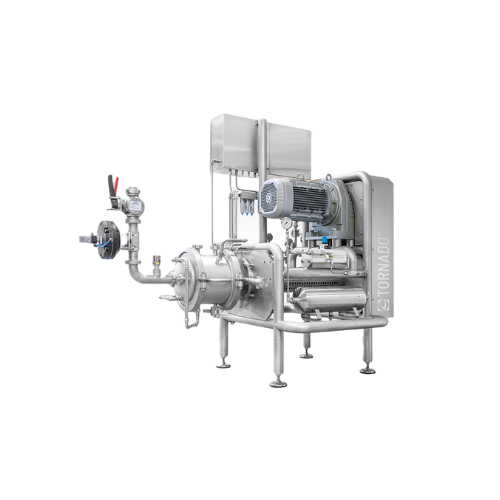

The TORNADO® series from CHOCOTECH offers pressurized aeration solutions specifically designed for continuous blending and mixing of sugar masses, chocolate, and bakery products. Featuring a dual aeration system with both pre-aerator and main aerator heads, this equipment precisely controls the texture and consistency of products such as marshmallows, aerated chocolate bars, and cream-filled candies. The aerating head utilizes meshing shearing pins with EDM-finished rotor and stator for intensive mixing. With throughput capacities ranging from 500 kg/h to 2000 kg/h depending on the model, TORNADO® efficiently caters to high-speed production lines in the food, confectionery, and bakery industries. The unit is designed for ease of maintenance, equipped with easily disassembled stator parts, integrated filters, and features an open hygienic design compatible with CIP applications. Multiple ingredient infeed ports and variable processing capabilities ensure versatile application, meeting the rigorous demands of modern production environments.

Benefits

- Enhances product texture and consistency with precise aeration control.

- Accommodates high-speed production demand with throughput up to 2000 kg/h.

- Simplifies maintenance through easy disassembly and CIP-compatible design.

- Reduces operational downtime with integrated filtration and robust construction.

- Supports versatile applications with multiple ingredient infeed capabilities.

- Applications

- Foam products, Candy, Sweets, Bakery products, Sugar masses, Chocolate

- End products

- Cream-filled candies, Whipped cream-filled pastries, Marshmallows, Aerated chocolate bars, Nougat, Meringues, Sponge cakes, Sugar-based foams

- Steps before

- Weighing, Dissolving, Cooking, Vacuuming, Caramelization, Crystallization

- Steps after

- Cooling, Metering, Forming, Tempering, Packing

- Input ingredients

- whipping agent solution, sugar mass, aerating gas

- Output ingredients

- fine pored stable foam mass, aerated sugar masses, aerated chocolate, aerated bakery products

- Market info

- CHOCOTECH is known for providing innovative solutions in the confectionery industry, specializing in machinery for processing and manufacturing chocolate, candies, and other sweets, with a reputation for precision engineering and tailored, high-quality equipment solutions.

- Aeration type

- Continuous

- Automation

- PLC-controlled

- Throughput light foam

- 500 kg/h - 1500 kg/h

- Throughput heavy foam

- 650 kg/h - 2000 kg/h

- EDM finish

- Stator, Rotor

- Cooling/Heating option

- Tempered rotor and stator

- Component type

- Rotor, Stator

- Gas type

- Compressed air or other gases

- Maintenance

- Easy disassembly of stator

- Design

- Open hygienic design for CIP

- Working mechanism

- Continuous Aeration

- Integrated steps

- Pre-aeration and main aeration

- CIP/SIP

- CIP capable

- Batch vs. continuous operation

- Inline Continuous

- Air incorporation control

- Meshing shearing pins

- Cleaning method

- Easy disassembly for maintenance

- Cleanability

- CIP application

- Machine footprint

- Compact

- Rotor and Stator configuration

- Pre-rotor and Pre-stator combination

- Discharge method

- Inline Continuous

- Aerating head

- Consists of rotor and stator

- Easily disassembled stator

- EDM finished

- Open hygienic design

- CIP application ready

- Multiple ingredient infeed ports

- Yes

- Integrated filters

- Yes

- Independent jackets for rotor and stator

- Two for stator, one for rotor

- Control panel type

- PLC with HMI

- Hygienic design

- Open hygienic design

- Integration capabilities

- CIP application

- Material of rotor and stator

- EDM finish

- Heating/Cooling options

- Tempered rotor and stator

- Disassembly features

- Stator easily disassembled

- Ingredient infeed ports

- Multiple

- Air/Gas integration

- Brooks FIC with filters

- Independent jackets

- Two for stator, one for rotor