Industrial vacuum mixers

Connect directly with world-leading production technology suppliers of innovative industrial vacuum mixers

A vacuum mixer mixes ingredients in an environment devoid of air to avoid incorporation of bubbles into the mix which can lead to foaming, formation of air pockets in the final product, fouling in heat exchangers, and cavitation. Mixing speed, level of vacuum, batch volume, nature and particle size of ingredients, heating or cooling requirements are all important considerations when selecting a vacuum mixer. Vacuum mixers are widely used in the pharmaceutical, chemical, and food industries for mixing ingredients sensitive to air.

What are you making?

Baby Food

Battered nuts

Brittles

Broth

Butter

Caramel

Cereal bars

Cheese spread

Chocolate bars

Chocolate coatings

Chocolate milk

Chocolate spread

Cookies

Cough syrup

Dough

Dry pet food

Electrolyte drinks

Extruded cereal

Fondant

Fruit puree

Granola

Granola bars

Halloumi

Hollow chocolate figures

Hyaluronic acid

Ice cream

Jam

Licorice

Lip gloss

Lipstick

Marmalade

Marshmallows

Mayonnaise

Nail polish

Plant-based cheese

Plant-based meat

Reaction flavors

Salad dressing

Sunscreen

Textured Vegetable Protein

Truffle balls

Truffle cream

Which industrial vacuum mixers technology do you need?

Industrial wet abrasive cut-off solution

Achieve precise cutting of complex shapes and hard materials while reducing noise ...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Chemically resistant dry scroll vacuum pump

Effortlessly manage aggressive substances and achieve reliable vacuum conditio...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

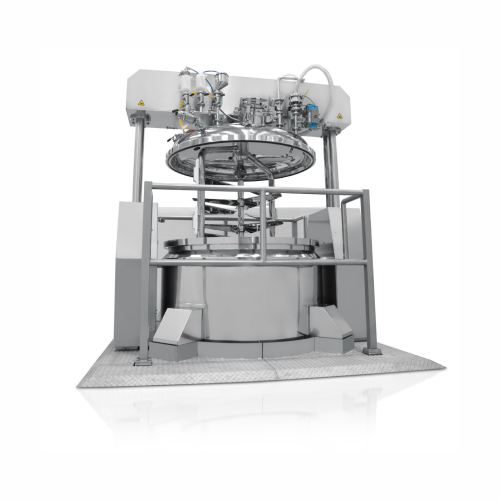

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Industrial automatic grinder for pork shoulders and chilled material

Efficiently process large pork shoulders and chill...

Cooling system for vegetables and meat

Optimize cooling efficiency with dual counterrotating agitators and expansive surfac...

Industrial mixer for vegetable, powder, rice, noodle blending

Effortlessly achieve consistent blends with this 100-liter...

Cottage cheese vat for efficient curds production

Maximize cheese yield while minimizing curd damage with this advanced v...

Laboratory dispersion reactor for 2l mixing and reaction processes

Streamline your laboratory processes with a versatil...

Easyclean design disperser for batch processing

Achieve precise homogenization and emulsification with a versatile dispers...

Laboratory dispersion reactor for 10l batch processes

Enhance precision and efficiency in lab-scale liquid formulations w...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Vertical vacuum dryer for heat sensitive products

Achieve optimal drying and mixing for your heat-sensitive and shear-sen...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

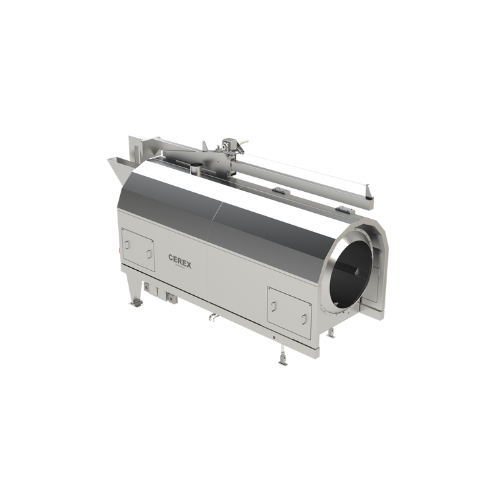

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Coaxial mixer for high viscosity liquids

Achieve seamless blending of high-viscosity materials with a coaxial mixer designe...

Universal industrial agitator for various fluid mixing needs

Optimize your production with an industrial agitator design...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Integrated plenum tablet coater

Achieve consistent and high-quality coatings on tablets with advanced airflow management, ef...

Vacuum transfer system for powders and granules

Effortlessly transfer and manage powders and granules with seamless integr...

Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

Thermally controlled pre-dough system

Achieve consistent flavor profiles in bakery products with a system designed for prec...

Drum and container emptying system

Ensure safety and efficiency when handling and emptying drums or containers, whether dea...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

High-speed wafer block building device

Streamline your wafer production with this high-speed device, expertly folding and p...

Laboratory vacuum mixer reactor for liquids and semi-solids

Achieve precise emulsification and mixing for high-viscosity...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Automated sous vide cooking and chilling system

Optimize your cooking process with a system that ensures consistent temper...

Gelatin melters for softgel production

Optimize your softgel production with a solution that ensures precise gelatin meltin...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

Hydro grind reactor for meat, vegetable, and vegan product processing

Achieve precision grinding and emulsification of ...

Compact massager for poultry, meat & seafood

Optimize your marination and curing processes with this compact massager, str...

Industrial batter mixer for food preparation

Achieve consistent batter quality with precise control over viscosity and tem...

Homogenizing mixer for product distribution

Optimize the flow of your production with a high-speed distributor mixer, ensu...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Negative pressure bin vent filter for dust control

Ensure optimal air quality and operational safety by effectively captu...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion s...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Dissolver for mixing and processing in lab and pilot plant

Optimize your material dispersion and homogenization processe...

Agglomerate dispersion solution for high viscosity materials

Optimize your production efficiency by integrating a dual-f...

Laboratory and production agitator for medium-sized containers

Streamline your mixing and agitation processes with a ver...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

Grinding and separating solution for meat processing

Optimize your meat and plant-based production lines by integrating a...

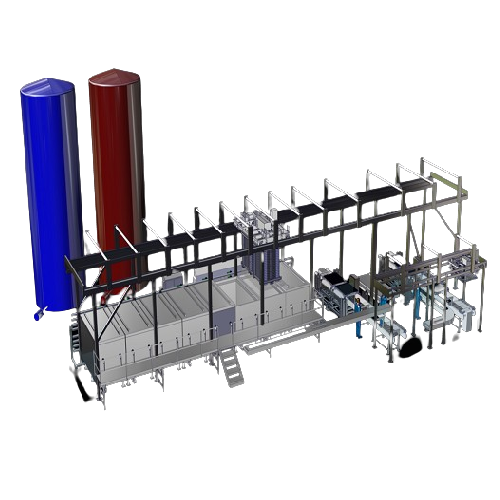

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Servo deposition system for industrial cake production

Effortlessly streamline your food production process with precise ...

Blower for vertical and horizontal grain transport

Efficiently transport grains, legumes, and flour both vertically and h...

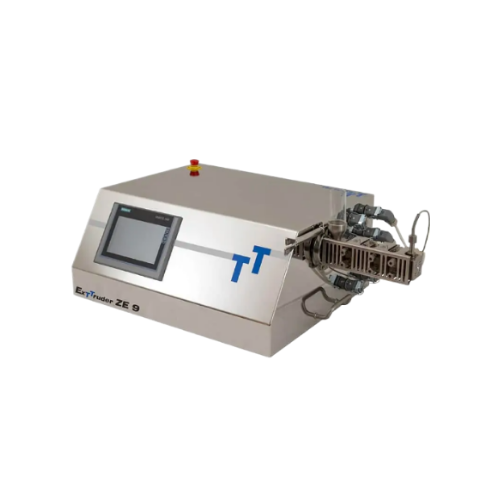

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

Industrial cooking kettle for heating, stirring, and chilling

Streamline your kitchen operations with a versatile cookin...

Turbo emulsifier for creams, gels, toothpastes

Achieve perfect emulsification and homogenization for your creams, gels, an...

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

Blending tank for food preparations

Optimize your production line with a tank designed for efficient blending and storage o...

Compact continuous aerator for bakery production

Optimize your bakery production with a compact aerator that delivers prec...

Pilot pharmaceutical aseptic separator and dryer

Achieve high-yield recovery of potent compounds with a separator that com...

Pharmaceutical aseptic separation system

Achieve precise separation and efficient drying of pharmaceutical powders with an ...

Sanitary mixer for food and pharmaceutical processing

Eliminate contamination risks while achieving high-speed, efficient...

Medium torque top entering mixer for complex mixing tasks

Optimize your production line with a versatile mixing solution...

Continuous knife peeler for root vegetables

Achieve high peeling yields and consistent quality with a versatile knife peel...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Continuous mixer for toothpaste production

When manufacturing toothpaste, dispersing and mixing powders into liquids to cr...

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Mixing tanks for liquid cosmetic products

When producing liquid solutions for cosmetics, such as eyeshadow, it’s vital to ...

Vacuum mixer for suspensions

The production of high quality pharmaceuticals often requires mixing of suspensions and similar...

Industrial food processor for cooking ready meals in different consistencies

In food industry production, the developm...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Industrial sous vide cooker

High temperatures, oxidation and evaporation from long sessions of conventional cooking can impa...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...