Making Hyaluronic Acid

Find innovative production technology for making hyaluronic acid and connect directly with world-leading specialists

Hyaluronic acid is a natural lubricant found in all mammals. An effective humectant, its molecules can hold a thousand times their weight in water. However, hyaluronic acid extraction is a complex biotechnological process that requires a specialized manufacturing technique.

Select your hyaluronic acid process

Tell us about your production challenge

Defat rooster combs at low temperatures before hyaluronic acid extraction

The rooster comb contains an appreciable amount of hyaluronic acid (HA), making it a primary source for production. Isolated and cleansed, the combs are reduced in size using a grinder before extraction.

The material is suspended in acetone at about 8°C for several hours to break down unwanted chemicals. The procedure is repeated until the combs are dried, resulting in a white, fibrous substance. This is then purified with saline citrate and centrifuged at a high rpm to separate the sediment from the gel-like extract.

Vacuum-dry processed HA to retrieve sodium hyaluronate

The hyaluronic acid extraction process can be refined to produce a highly-concentrated sodium hyaluronate. The derivative is the salts of HA and is used primarily in medical formulations and cosmetic creams.

Manufacturers treat extracted hyaluronic acid with a water-based solvent and pass the substance through a vacuum dryer. The process obtains sodium hyaluronate in the form of a powder that can be then mixed with other materials and chemicals.

Manufacture vegan hyaluronic acid in batch to address stability concerns

Non-animal hyaluronic acid is produced by fermenting a safe strain of bacteria from plants like wheat. Although continuous production prolongs the lifetime of bacterial cultures, the high dilution rate in a chemostat presents a challenge to molecular stability. For this reason, manufacturers typically rely on batch processes.

Plant-based oral dosage types such as HPMC mean that HA supplements can be completely vegan. However, non-animal products are more frequently designed for skincare products.

Target osteoarthritis and other issues with hyaluronic acid supplements

The human body generates hyaluronic acid, but the levels decrease with age. In fact, HA products are primarily designed to treat problems related to osteoarthritis.

However, hyaluronic acid supplements are also thought to prevent various issues, from chronic fatigue syndrome to fibromyalgia. HA is a versatile material distributed in solid, liquid, or semi-solid formats. But nutraceutical preparations are often found as capsules, tablets, or softgels.

Processing steps involved in hyaluronic acid making

Which hyaluronic acid technology do you need?

In vitro subcutaneous injection simulator

Optimize drug formulation screening and selection with an innovative solution th...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

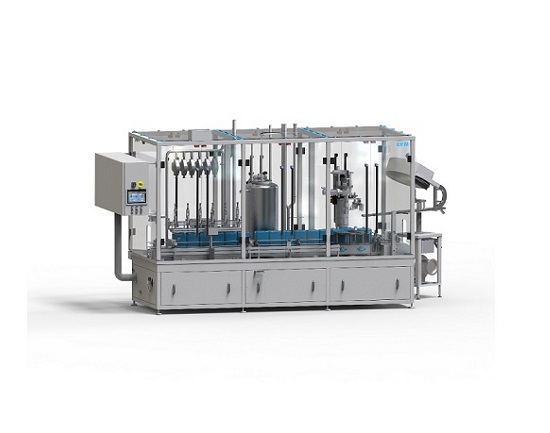

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Microencapsulation system for your drug delivery system

Whether you want to improve the stability of nutrients, protect a...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

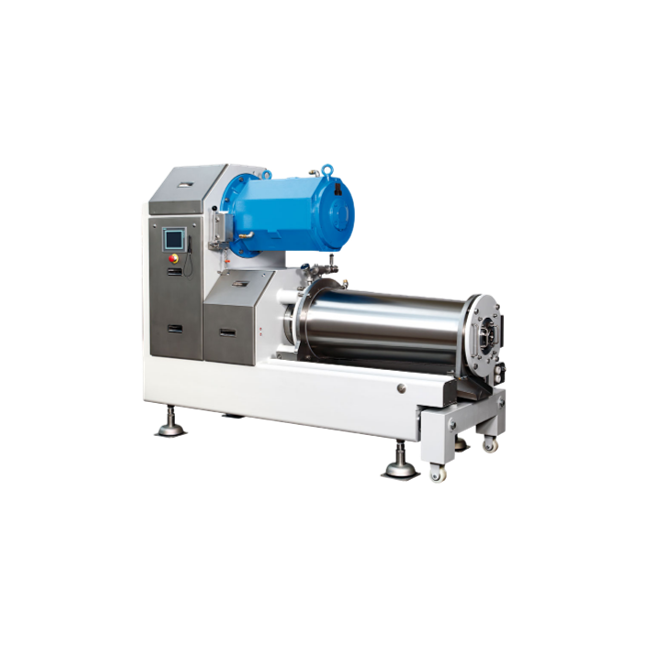

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...

Checkweigher for stand-up pouches

When working with several lines of stand-up pouches, you can benefit from controlling the...