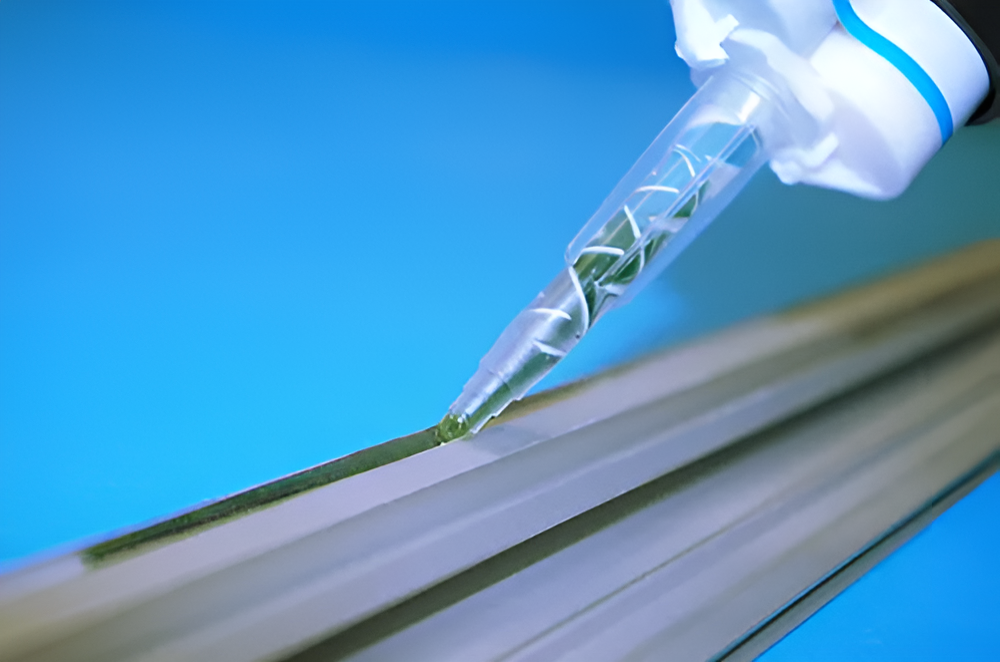

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion system, ideal for enhancing efficiency and precision in stirring, mixing, and homogenizing processes, while eliminating the need for cleaning between batches.

Processes and Mixes Industrial Liquids and Slurries

The DISPERMAT® SC4 dissolver from VMA-GETZMANN is designed for precise mixing and dispersion in a variety of industrial environments, including pharmaceuticals, automotive, and agrochemicals. It employs a high-torque motor with adjustable speed control, facilitating efficient dispersion of materials such as battery slurries and liquid fertilizers. With a capacity of 30 to 600 liters, it integrates seamlessly into existing production lines via PLC controls, offering energy efficiency with variable-speed motor optimization. Available in standard and ATEX-compliant models for explosive environments, it meets stringent industrial standards. Maintenance is streamlined with options for CIP systems and stainless steel construction ensures corrosion resistance. Custom configurations and direct engineering support are available for tailored applications.

Benefits

- Enhances production efficiency by ensuring consistent material dispersion.

- Reduces operational costs with energy-efficient variable-speed motor technology.

- Ensures safety and compliance in explosive environments with ATEX-certified options.

- Adapts to diverse production needs with customizable speed and capacity configurations.

- Minimizes cleaning time and contamination risk with easy maintenance and CIP systems.

- Applications

- Sealants, Printing inks, Architectural coatings, Ceramic/glass products, Agrochemicals, Liquid crystal displays, Carbon materials, Cosmetics, Adhesives, Food products, Automotive paints, Batteries, Fertilizers, Plant protection products, Pharmaceuticals

- End products

- Liquid nitrogen fertilizer, Nano-encapsulated drugs, Ceramic glazes, Oled screens, Interior wall paint, Structural adhesives, High-performance inkjet inks, Silicone sealant, Reinforced carbon nanotubes, Anti-aging face cream, Corn herbicides, Lithium-ion battery slurry, Fruit concentrate pastes, Glyphosate formulation, Automotive clear coat

- Steps before

- Pre-dispersion, Material weighing, Raw material mixing, Pre-milling, Particle size reduction

- Steps after

- Homogenization, Filling, Quality control, Packaging, Final product testing

- Input ingredients

- active ingredients, excipients, nutrients, water-soluble powders, liquids, growth-promoting substances, growth inhibitors, raw materials, solids, pigments, binders, solvent-based paints

- Output ingredients

- slurries, homogeneous distribution, high-quality plant protection products, finely dispersed mixtures, coatings, paints, ink for printing, polishing agents, screen printing inks, textile inks

- Market info

- VMA-Getzmann is renowned for manufacturing high-quality dispersing, mixing, and milling equipment, particularly for the chemical, coatings, and inks industries, specializing in engineered-to-order solutions that emphasize innovation, reliability, and technical excellence.

- Power

- 0.3 - 55 kW

- Capacity

- 0.05 - 2000 litres

- Control

- CN / C / SC / PLC

- Container type

- Single-walled / Double-walled

- ATEX Certification

- EX

- Product Volume

- 50 - 1600 litres

- Cooling option

- None specified

- Automation

- Manual / PLC-controlled

- Vacuum Capability

- Available

- Filling Accuracy

- None specified

- Batch vs. Continuous

- Batch

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Type

- Single-walled / Double-walled

- Tank shape and size

- 30–2500 litres

- Control panel type

- PLC / CN / SC / C

- Control panel type

- CN / C / SC / PLC

- Integration possibilities

- Modular quick-change systems

- Compliance with ATEX

- Yes

- Container type

- Double-walled / Single-walled

- Scraper system

- Optional high torque scraper system

- Modular system flexibility

- Mixing, homogenizing, fine grinding