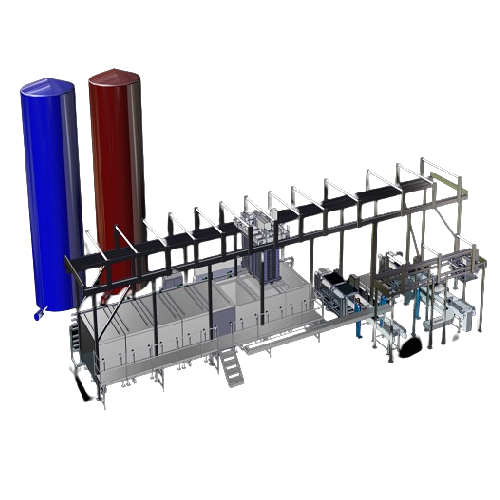

Automated sous vide cooking and chilling system

Optimize your cooking process with a system that ensures consistent temperature control and uniform cooking for a variety of ready meals, enhancing flavor profiles while reducing energy usage and labor costs.

Cooks, Chills, and Vacuum Seals Sous Vide Meals

The Thermix™ Sous Vide Cooking and Chilling System from Armor Inox offers a fully automated, continuous production line solution specifically designed for industrial food processors. It employs an immersive water cooking and chilling method that ensures efficient thermal transfer, delivering uniformly cooked products with superior taste profiles. This system integrates seamlessly with existing production lines, handling processes such as cooking, vacuum sealing, and chilling to produce a range of sous vide meals, including beef bourguignon and chicken tikka masala. With a throughput of 0.5 to 5 tons per hour, it addresses high-volume demands while minimizing labor requirements. The Thermix™ system is energy-efficient, using continuous circulation to reduce energy consumption. Available in robust, corrosion-resistant materials, it meets strict food safety and traceability standards, offering clean label production. Additionally, the system’s streamlined design and low-maintenance operation contribute to reduced processing costs, while customization options are available to tailor the equipment to specific production needs.

Benefits

- Enhances product quality and consistency, ensuring a superior taste profile.

- Minimizes labor and waste through fully automated cooking and chilling processes.

- Extends shelf life without preservatives, ideal for clean label products.

- Reduces energy consumption with efficient thermal transfer.

- Streamlines operations with continuous, high-speed throughput of up to 5 tons per hour.

- Applications

- Ready meals, Sauces, Retail market entrees, Delis, Hams, Hot dogs, Vegetables, Sous vide meals

- End products

- German bratwurst, Vegan curry with tofu and vegetables, Pork belly confit, Turkey breast roulade, Glazed spiral ham, Beef bourguignon, Chicken tikka masala, Roasted asparagus, Smoked pastrami, Marinara sauce, Steamed broccoli, Bechamel sauce

- Steps before

- Raw Preparation, Vacuum Sealing, Portioning, Seasoning

- Steps after

- Chilling, Product Packaging, Labeling, Distribution

- Input ingredients

- raw food products, vacuum-sealed ingredients, seasoned food portions

- Output ingredients

- sous vide cooked meals, high flavor profile products, ready-to-eat sous vide products

- Market info

- Armorinox (Middleby) is known for manufacturing custom-engineered stainless steel solutions for industrial applications, particularly in the food processing and commercial kitchen equipment sectors, focusing on quality, durability, and innovation.

- Automation

- Fully automated

- Capacity

- 0.5 to 5 tons per hour

- Energy Efficiency

- Energy efficient thermal transfer

- Cooking Method

- Immersive water cooking

- Chilling Method

- Immersive water chilling

- Temperature Control

- Uniform temperature delivery

- Maintenance

- Exceptionally low maintenance costs

- Processing Speed

- Steady pace

- Product Flexibility

- Optimum product flexibility

- Labor Involvement

- Minimal human labor involvement

- Automation level

- Fully automated

- Working mechanism

- Continuous cook, chill

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Low energy usage

- Cleaning method

- CIP (Clean-in-Place)

- Heat sensitivity

- Yes/No

- Shelf life

- Long/Short

- Container type

- High barrier envelope

- Product consistency

- Uniform/Variable

- Compact footprint

- Customizable

- Discharge method

- Continuous

- Tank shape

- Rectangular

- System throughput

- 0.5 to 5 tons per hour

- Control panel type

- Automated

- Integration possibilities

- PLC / SCADA

- Custom automation levels

- Manual / Semi-Automatic / Fully Automatic