Industrial wet abrasive cut-off solution

Achieve precise cutting of complex shapes and hard materials while reducing noise with this reliable wet abrasive cut-off machine, designed to handle continuous long parts in a spacious chamber, supporting high-quality preparations in metal and composite material testing.

Precisely Cuts and Clamps Complex Metal Samples

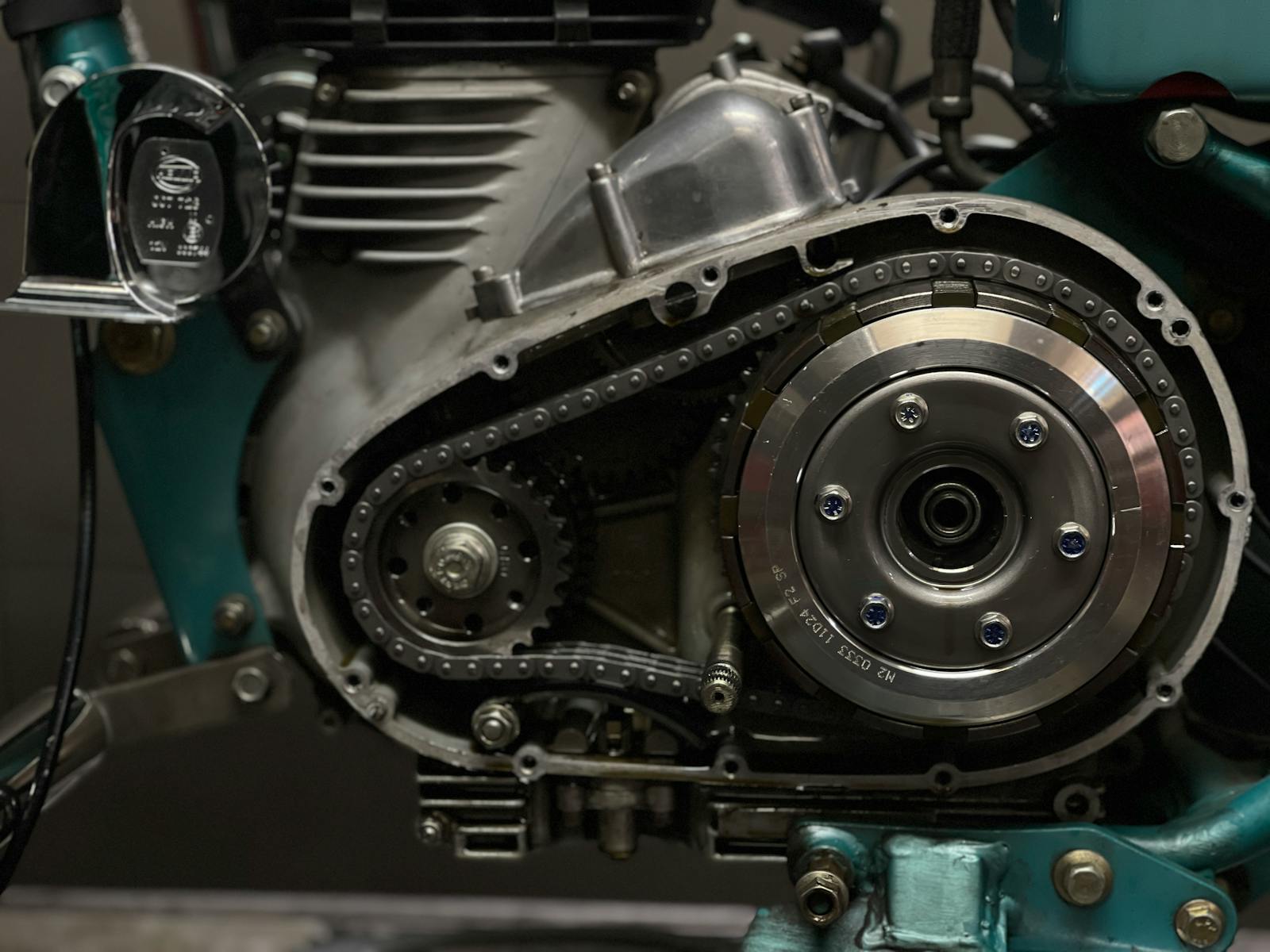

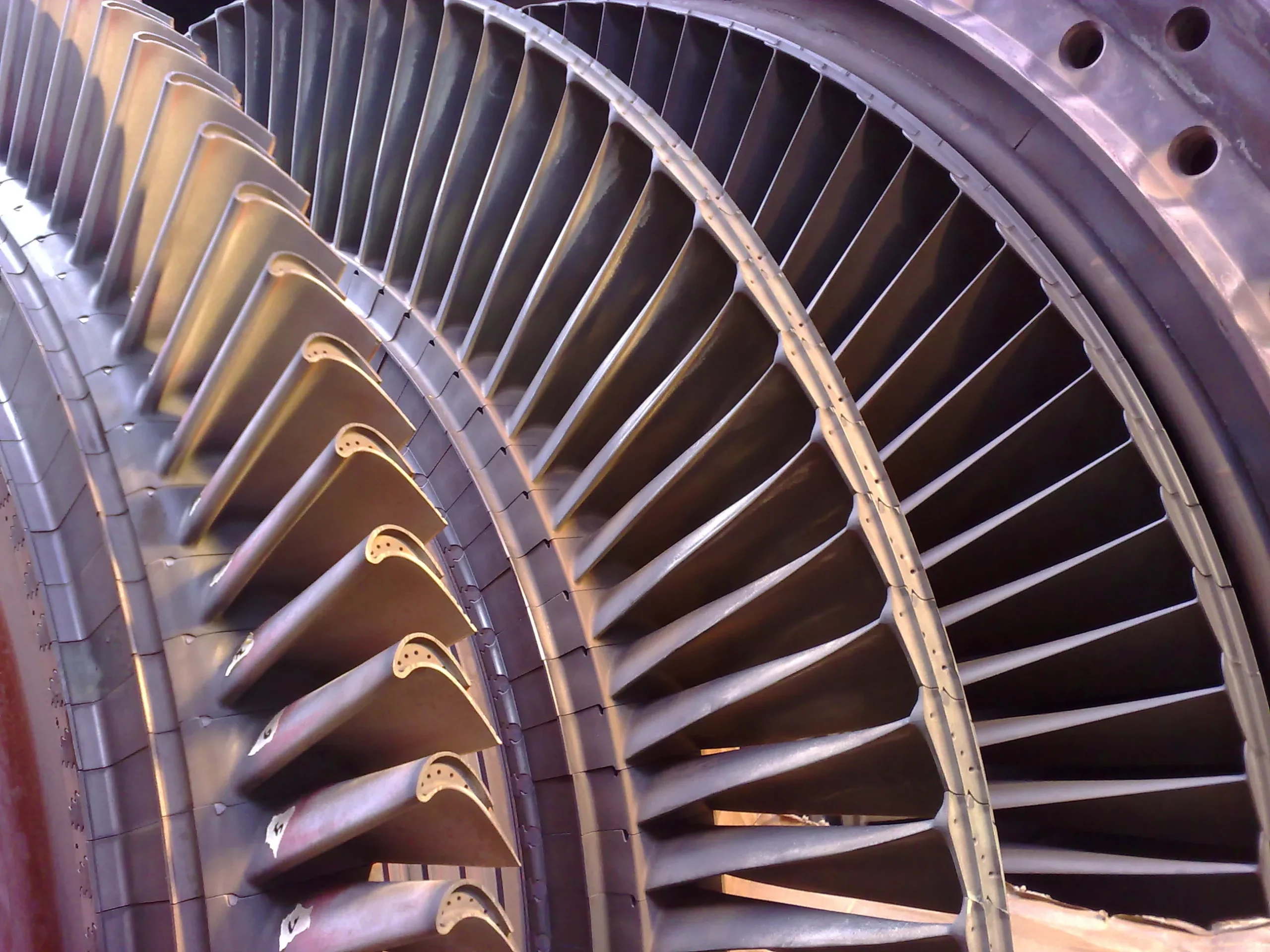

The Brillant 255 from ATM Qness GmbH is a versatile wet abrasive cut-off machine designed for complex cutting tasks in research laboratories and industrial settings. This unit distinguishes itself by offering precise, low-noise cutting of hard and composite materials using a manual travel system in two axes, with an optional Z-axis for parallel serial cuts. Ideal for applications including test specimens, turbine blades, and automotive components, it efficiently manages complex geometries and continuous long parts with its spacious cutting chamber and reliable clamping systems.

The Brillant 255 accommodates cutting wheels up to 400 mm in diameter, providing a cutting capacity of up to 150 mm. The machine features a robust, powder-coated aluminum construction, ensuring durability. Its LED-illuminated cutting chamber enhances visibility, promoting accuracy during operation. The equipment integrates seamlessly with production lines, offering flexibility in bench-top or floor-standing configurations and enabling manual operations for tailored handling of each cut.

Energy-efficient and designed to reduce operational noise, this machine supports manual horizontal and vertical adjustments, catering to specific cutting needs with minimal disturbance. Its flange with ceramic protector and extensive range of clamping tools ensure high-quality cuts while maintaining safety standards through a door interlocking system. Customization options and ongoing engineering support from ATM Qness GmbH back up the Brillant 255, offering additional confidence to users requiring specialized cut-off solutions.

Benefits

- Enhances precision in cutting complex geometries with manual multi-axis control.

- Maintains operational safety with an advanced door interlocking system.

- Lowers energy costs with efficient LED illumination and optimized motor control.

- Minimizes noise pollution, ensuring a quieter work environment.

- Handles diverse materials, from ceramics to polymers, promoting versatility.

- Applications

- Metal samples, Ceramic materials, Steel, Tool components, Hard materials, Geometric shaped samples, Polymer materials, Aluminum, Engineered components, Composite materials, Continuous long parts

- End products

- Steel reinforcement bars, Industrial machinery components, Engine blocks, Precision machined tools, Turbine blades, Automotive drivetrain components, Cutting tools, Reinforced composite panels, Aluminum extrusion profiles, Polymer panels, Ceramic insulators, Test specimens, Aerospace fuselage panels

- Steps before

- Mounting, Clamping, Fixture setup

- Steps after

- Polishing, Etching, Hardness Testing, Material analysis

- Input ingredients

- metal samples, geometric shaped samples, long parts, materials for cutting

- Output ingredients

- cut samples, precise cuts, serial cuts

- Market info

- QATM is renowned for its expertise in manufacturing high-quality metallographic equipment and consumables, providing innovative solutions for material testing and analysis, which are trusted by laboratories and quality control professionals globally.

- Cutting Wheel Diameter

- Up to ø 400 mm/16"

- Max. Cutting Capacity

- ø 150 mm

- Wheel Flange Size

- ø 32 mm

- Y-axis Travel

- 170 mm (manual)

- X-axis Travel

- 345 mm (manual)

- Table Size (Z-axis fixed,not adjustable)

- 550 x 375 mm, stainless

- Table Size (manual/automatic)

- 420 x 375 mm, stainless

- T-slot Size

- 12 mm

- Connection Power

- 12 kVA

- Drive Power (Main Drive)

- 7-8 kW S1

- Machine Dimensions (W x H x D)

- 1100 x 1600 x 930 mm

- Machine Weight

- ~ 450 kg

- Cutting Mechanism

- Wet abrasive

- Travel Axes

- Manual Y/X, Optional Manual Z

- Operation Type

- Manual travel with optional lateral wheel wrench

- Cutting Capacity

- Up to ø 150 mm

- Vibration Reduction

- Low noise design

- Continuous Material Cutting

- Opening on sides

- Safety Features

- Door interlocking system

- ISO compliance

- ISO 9001 / ISO 14001

- Machine footprint

- 1100 x 1600 x 930 mm

- Weight

- ~ 450 kg

- Cutting wheel diameter

- up to ø 400 mm/16"

- Cutting capacity

- ø 150 mm

- Table size (fixed)

- 550 x 375 mm, stainless

- Table size (manual/automatic)

- 420 x 375 mm, stainless

- T-slot

- 12 mm

- Material

- Powder-coated aluminum

- Clamping system

- T-slot table with clamping tools

- Chamber illumination

- LED flex light

- Control panel type

- Manual/Automated

- Integration possibilities

- Optional Z-axis for parallel serial cuts

- Clamping system options

- Various clamping tools available

- Movement customization

- Manual vertical and horizontal movement

- Cutting wheel size options

- Up to ø 400 mm