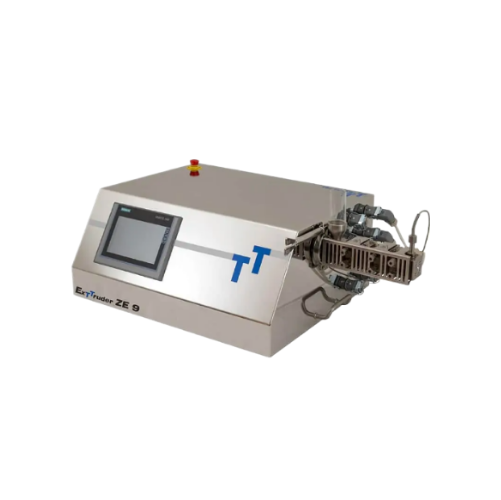

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streamlines small-batch production, offering customizable co-rotating screw configurations for intricate processing tasks such as mixing and cooling.

Processes and Compounds Solids and Liquids

The ZE 9 HMI mini extruder from Three-Tec GmbH is a versatile table-top solution engineered for precision in conveying, kneading, and mixing applications. Designed for use in the pharmaceutical, biotech, and chemical industries, it excels in developing products like insulin, paracetamol tablets, and enzyme formulations. This extruder offers up to eight heating zones with quick heating time, a customizable array of screw segments for varied processing tasks, and the choice of water, air, or liquid nitrogen cooling. Its compact, touch-panel-operated design makes it ideal for research and development environments where spatial efficiency and flexibility are crucial. Constructed from corrosion-resistant 316L stainless steel, it meets stringent sanitary standards and can be configured to comply with specific regulatory requirements. The ZE 9 HMI ensures precise control and repeatability, supported by customization options in L/D ratios and operational parameters tailored to your unique processing needs.

Benefits

- Enhances versatility in R&D with customizable screw configurations.

- Saves space without compromising functionality, ideal for lab environments.

- Ensures precise thermal control for consistent product quality.

- Meets strict hygiene standards with corrosion-resistant materials.

- Facilitates multiple cooling options for tailored process efficiency.

- Applications

- Supplements, Vitamins, Metal powders, Liquid formulations, Fine chemicals, Pharmaceutical tablets, Detergents, Nutraceuticals, Pharmaceutical powder, Biopharmaceuticals, Enzymes, Sweets, Coating materials

- End products

- Gummy bears, Syrup formulations, Riboflavin, Amylase, Insulin, Coenzyme q10, Washing powder, Iron powders, Ascorbic acid, Paracetamol tablets, Gelatin coatings

- Steps before

- Material Preparation, Mixing, Feeding

- Steps after

- Cooling, Pressure Testing, Material Discharge

- Input ingredients

- raw materials, plastics, polymers, powder, granules

- Output ingredients

- extrudates, profiles, filaments, pellets, compounded material

- Market info

- Three-Tec is known for its expertise in manufacturing precision dosing and feeding systems for industrial applications, with a strong reputation for customizable engineered-to-order equipment and innovative solutions tailored to specific customer needs.

- Screw Diameter

- 9 mm

- Max Pressure

- 200 bar

- Max Torque

- 14.5 Nm

- Max Temperature

- 230 °C (400 °C optional)

- Heating Zones

- 1-8

- Heating Time

- 4 min (100 °C) / 10 min (200 °C)

- Material

- Stainless steel 316 L (1.4404) etc.

- L/D Ratio

- 15

- Operation

- Touch panel

- Dimensions (L x W x H)

- 650 x 400 x 260 mm (excluding barrel)

- Cooling options

- Water / Air / Liquid Nitrogen

- Automation Level

- Touch panel control

- Screw configuration

- Co-rotating

- Customizability

- Screw segments for various functions

- Pressure measurement

- At the die

- Cooling medium

- Water / Air / Liquid Nitrogen

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cleanability

- High, due to stainless steel 316L

- Biological compatibility

- N/A

- Machine footprint

- 650 x 400 x 260 mm

- Control panel type

- Touch panel

- Cooling options

- Water / Air / Liquid nitrogen

- Screw segments

- Conveying / Kneading / Mixing / Compacting / Pressing / Decompressing / Reverse conveying

- Automatic feeder types

- Solid / Liquid

- Pressure measurement

- At the die

- Operation interface

- Touch panel