Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high homogeneity and efficiency, ensuring minimal residue through advanced vertical vacuum technology for seamless integration into existing production lines.

Blends and Homogenizes Bulk Solids Efficiently

The SOLIDMIX Vertical Pharma Vacuum Blender from EKATO is engineered for high-performance blending of powders and granules, catering to chemical, pharmaceutical, and food industries. Its innovative vertical mixer design optimizes the mixing process, using a conical bottom and EKATO SOLIDS-PARAVISC impeller for efficient, homogeneous blending with minimal product residue. Available in various capacities up to 32,000 liters, it supports diverse batch sizes from pilot to full production scales. The SOLIDMIX system integrates seamlessly with existing production lines, featuring CIP systems for efficient, contamination-free cleaning, and ATEX-certified versions for use in hazardous environments. Engineered for energy efficiency, it ensures low operational costs, while customization options allow tailored solutions to specific process needs.

Benefits

- Ensures consistent product quality through homogeneous blending of bulk solids.

- Minimizes operational costs with energy-efficient mixing technology.

- Increases productivity with rapid process times and easy scale-up.

- Reduces maintenance efforts with CIP compatibility and minimal product residue.

- Accommodates safety requirements with ATEX-certified options for hazardous environments.

- Applications

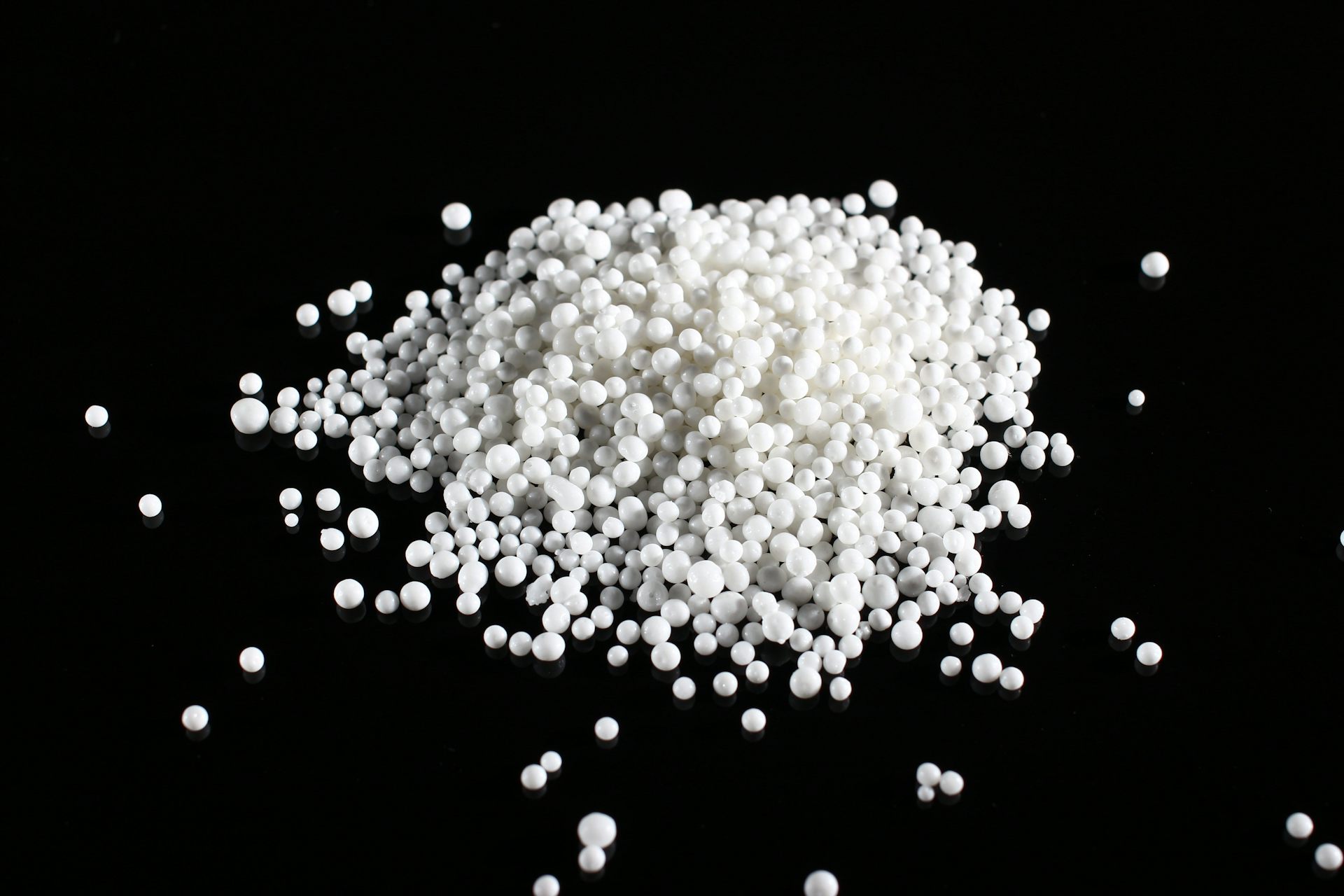

- Food, Metal powders, Fine chemicals, Environmental applications, Polymer additives, Pigments, Fertilizers, Pharmaceuticals

- End products

- Iron oxide, Dyes, Nutraceutical blends, Colorants, Instant soup mixes, Ammonium nitrate, Urea, Aluminum powders, Excipients, Snack seasoning blends, Stabilizers, Plasticizers

- Steps before

- Purification, Grinding, Pre-mixing, Weighing

- Steps after

- Packing, Coating, Quality Control, Sterilization

- Input ingredients

- fine chemicals, pigments, fertilizers, metal powders, polymer additives, free-flowing goods, liquid products, viscous products, pasty products

- Output ingredients

- homogeneous mixtures, mixed solids, fine chemical blends, pigment mixtures, fertilizer blends, metal powder blends, polymer additive mixes

- Market info

- Ekato is renowned for its expertise in mixing technology and process engineering, providing innovative and high-quality solutions for industrial mixing processes across various sectors, including chemical, pharmaceutical, and cosmetics industries.

- Mixing Capacity

- 100 L to 32, 000 L

- Geometry Type

- Conical Bottom

- Drive Type

- Free-overhung

- Wall Clearance

- Small

- Impeller Type

- EKATO SOLIDS-PARAVISC

- Energy Efficiency

- High

- Shearing Effect

- Minimal

- Power Input

- Low Maintenance

- System Components Available

- CIP, ATEX

- Effective Volumes

- 50 L to 6, 300 L

- Emptying Efficiency

- Almost Complete

- Automation Level

- CIP system

- ATEX Version

- Zone 0 to Zone 2

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Working mechanism

- Vertical mixing with EKATO SOLIDS-PARAVISC or EKATO ISOPAS impeller

- Integrated steps

- Mixing, Cleaning in place (CIP)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Varied based on model size

- Vessel Shape

- Conical bottom

- Discharge Method

- Almost complete emptying with minimal yield rates

- Drive Shaft

- Free-overhung

- Impeller Type

- EKATO SOLIDS-PARAVISC / EKATO ISOPAS

- Effective Volumes

- 50 L to 32, 000 L

- Weight

- 600 kg to 20, 000 kg (depending on model)

- Impeller type

- EKATO SOLIDS-PARAVISC / EKATO ISOPAS