Let's make makeup

Find innovative makeup equipment and connect directly with world-leading technology suppliers

Although not all women use makeup every day, almost all of them own at least one makeup product, be it lipstick or face powder. Most makeup products share the same basic ingredients of waxes, oils, and fillers with pigments like iron oxide used for colors and shades. Makeup manufacturing equipment includes pulverizers, mixers, and mechanical press machines to produce cosmetic products in different forms such as powder, liquid, or mousse.

Top picks for producing make up

Mascara and lip gloss filling and capping system

Optimize your cosmetic production line with a high-speed system designed ...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Makeup blusher compacting machine

When producing high-quality compressed powder cosmetics, control of the pressing process ...

Mixing tanks for liquid cosmetic products

When producing liquid solutions for cosmetics, such as eyeshadow, it’s vital to ...

Select your makeup process

What are you making?

Tell us about your production challenge

From lipstick to mascara – makeup manufacturing equipment in production lines

Makeup manufacturing process requires the use of multiple makeup manufacturing equipment. Grinders and pulverizers mill ingredients into fine sizes before blending them with other elements. Mixers and temperature-controlled tanks with agitators can help you maintain the texture and structural integrity of the product. The amount of the ingredients and how well it is mixed will give your makeup product its distinct properties such as covering power, absorption or adhesiveness. Equipment and ingredients obviously change based on the product you’re making.

For instance, in the case of compacted powder, the final mixture is compacted using a mechanical pressing machine to form a “cake” structure in containers. Lipsticks and mascaras are produced from a mixture of waxes, oils, and pigments. Eyeshadow relies on pigments, fillers, and binders to form its structure and hold its place when applied. Makeup products are also mixed with preservatives to have a longer life and to prevent them from deteriorating quickly.

Regulations in cosmetic industry

Regulations for cosmetics are based on the safety of consumers, but they vary from country to country. In the EU, the regulations are more stringent. The products go through safety assessments and there are more chemical ingredients that are prohibited for use compared to the list in US regulations. Some chemicals like lead and parabens are banned in Europe but are not banned in the US.

Chemical ingredients that are found or suspected to cause cancer, irritation, birth defects, or mutations are strictly prohibited. Aside from a list of chemical ingredients that are prohibited, cosmetic manufacturers are required to indicate details of the product such as ingredients, manufacturer contact details, country of origin, legal compliance, net quantity of the product, etc. in their product label.

Mineral-based makeup – is it the same as organic makeup?

Mineral makeup has been making a splash in recent years. That’s because there’s a trend to look for products that are increasingly safe and chemical-free. The problem is that people assume that the word mineral means organic and natural. Half-truth. It is natural but it is not organic. Mineral-based and organic makeup come both from natural ingredients. The difference is that mineral makeup doesn’t contain anything that is plant or animal based. It is made from naturally occurring minerals like zinc or titanium dioxide that are micronized, or ground and milled to produce the powders necessary for the formulation of the product. Organic makeup instead, is made primarily from carbon-based ingredients like plants that are grown without any pesticides, herbicides, and insecticides.

As for chemical ingredients, mineral makeup contains fewer chemicals than regular makeups. But that doesn’t mean they are always completely chemical-free. Especially if these products are in liquid form, they may contain paraben preservatives. Also, not all minerals are good even if they are pure and natural; for example, some mineral makeup companies have started removing a mineral called bismuth oxychloride because it may be dangerous to some people.

Which makeup technology do you need?

Makeup blusher compacting machine

When producing high-quality compressed powder cosmetics, control of the pressing process ...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

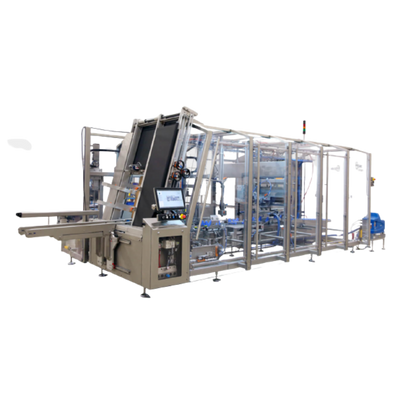

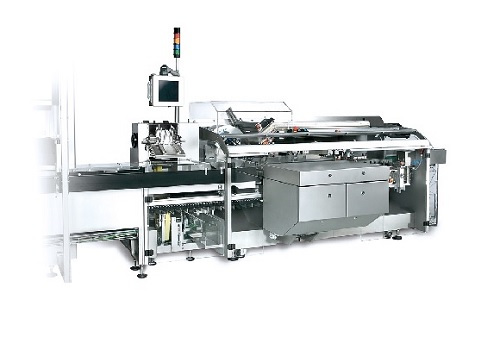

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Semi-automatic mascara bottle filling and capping

Streamline your production line with a solution designed for precision ...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Side Load Case Packer For Facial Tissues

When packing facial tissue boxes into large cases at high speeds, adjustable infee...

Facial Tissue Box Cartoning Machine

Tissues come in various formats, such as men’s sizes, family boxes, or travel tissue pa...

R&D bottle washer

When you pack your products in bottles, vials, syringes, and test tubes you need to wash them before fillin...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

Hot air tunnel for shrink sleeve labels

Sleeves are very popular in food, beverage, Chemical and pharmaceutical industry be...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Semi-automatic blister sealing machines for retail

Blister packaging is mostly used in retail packaging for food, electro...

Semiautomatic blister sealing machines for medical devices

Mostly used in the pharmaceutical and medical industries, bli...

Thermoforming vacuum and pressure machine for tray production

Thermoforming is the process of converting a plain plastic...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

Automatic lipstick filling machine

Lipsticks, lip balms and lip glosses are very popular cosmetic products that require hig...

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

Manual cosmetic powder press

The design, manufacture and testing of new cosmetic powder products require a small-scale press...

Drop tester for compacted powders

A key requirement for cosmetic compressed powder products is that they maintain their com...

Mixing tanks for liquid cosmetic products

When producing liquid solutions for cosmetics, such as eyeshadow, it’s vital to ...

Vibrating screen for cosmetic powders

Dense or viscous compounds can be difficult to prepare for use in cosmetic products. ...

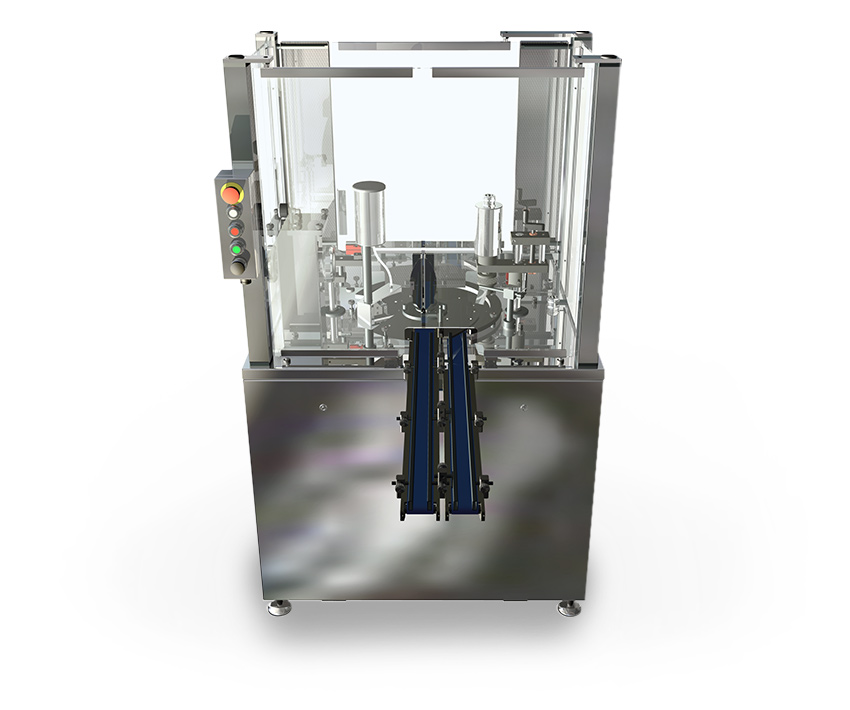

Cosmetic powder pressing machine

For the medium and large-scale production of compressed powder cosmetics, a fully-automatic...

Powder pressing mould

Traditional powder pressing moulds are based on plain shapes or basic designs. In order to differentiat...

Mascara filling machine

For smaller production volumes, a fully automatic filling solution for mascara, eyeliner, lip gloss a...

Compact powder pressing machine

Pressed powder products are extremely popular in cosmetics, but their production has challen...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

Wet Wipes Packaging Machine

Sachet packaging is a convenient and popular wrapping method for a wide range of products in the...

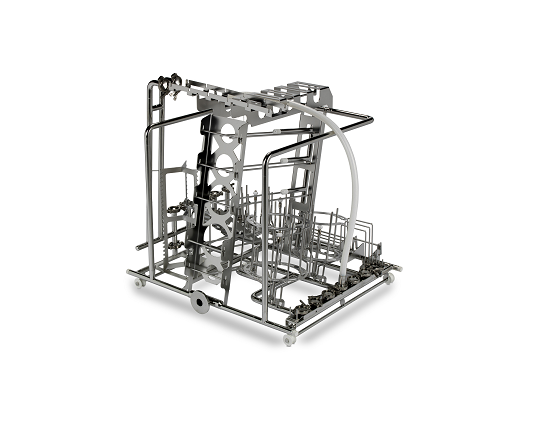

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

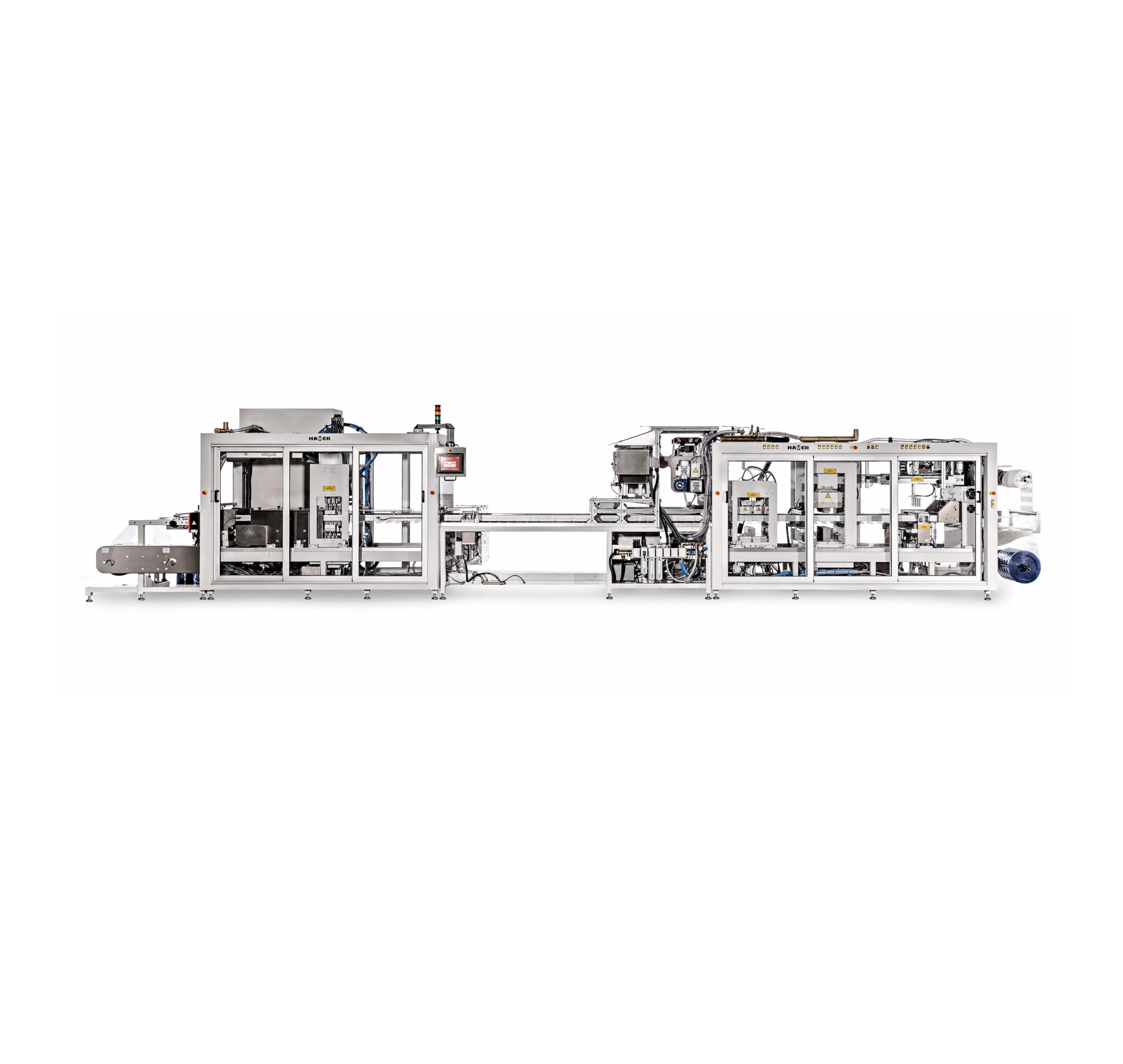

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

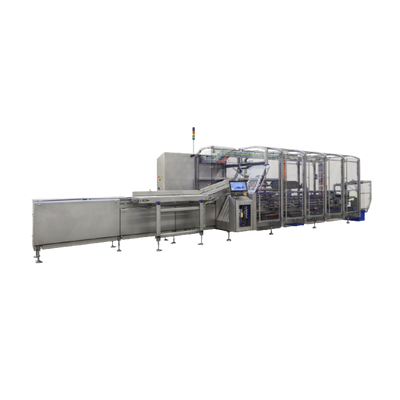

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

Automatic mascara filling machine

Do you need to increase your efficiency and production volumes whilst reducing your costs...

Automatic nail polish filling machine

Do you need to increase your production volumes in the most efficient way possible? A...

Semi-automatic filling machine for nail polish

Do you need to automate a smaller cosmetic line without the large costs ass...