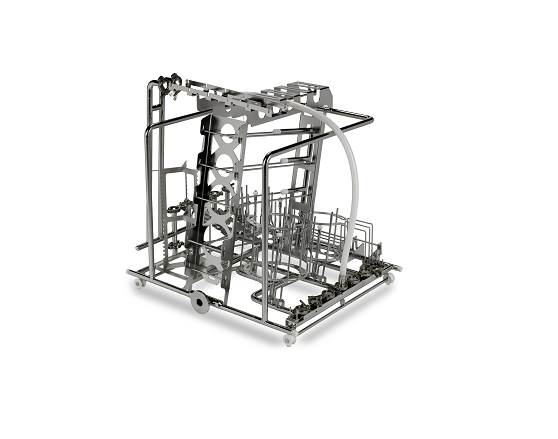

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a way as to guarantee flushing of even the most hidden parts. For all but the simplest of parts, simply stacking them is not enough. A fully customised washer basket not only ensures perfect cleaning of all types of product contacting parts but also maximises the throughput of the washer, reducing downtime by shortening cleaning cycles.

Bespoke GMP Washer baskets to maximise cleaning performance and efficiency

The IWT Pharma Baskets are custom-designed to your exact requirements. Engineers take detailed studies of all the parts that you require to be washed in order to build the optimum loading basket suited to all types of item – from drums to hoses, to filling needles, punches, dies, and more.

Key drivers in the design of the custom baskets are optimal cleaning performance, ensuring each product is able to be completely and thoroughly washed, no matter shape or construction; maximising throughput, optimising each load to reduce line downtimes associated with parts washing; intuitive loading, allowing operators to quickly and easily place parts without any complex insertions.

Loading baskets are made entirely from AISI 316L with ASME-BPE fully-welded piping to distribute washing solution around the load. For ease of use and speed of operation, the connections from basket to washer use patented quick lock connectors.

Benefits

- Bespoke design ensures perfect, repeatable cleaning results of even the most complex parts

- Computer-modelled water flow to ensure optimised flushing and rinsing

- Maximise throughput, optimising number of parts per wash cycle

- Works with IWT Pharma 200 and 300 series COP contact part washers