Plant Extraction Equipment

Find innovative plant extracts equipment and connect directly with world-leading technology suppliers

Ancient civilizations discovered that plant extracts were useful for the treatment of pathologies. The origin of plant extraction cannot be specifically verified, but we can infer that the earliest attempts at plant extraction were more intuitive than scientific. Today, the extraction of compounds is a precise process with plant extraction systems complimenting traditional knowledge.

Innovative solutions for producing plant extracts

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

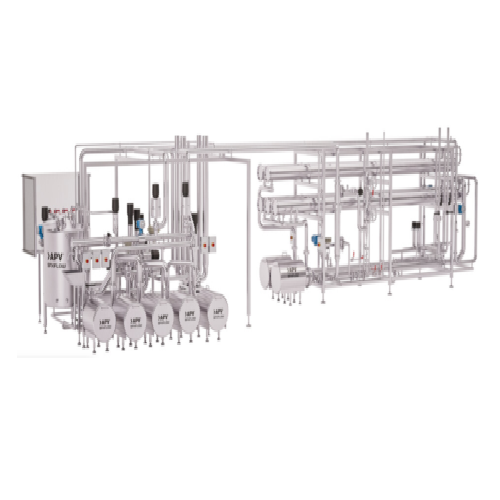

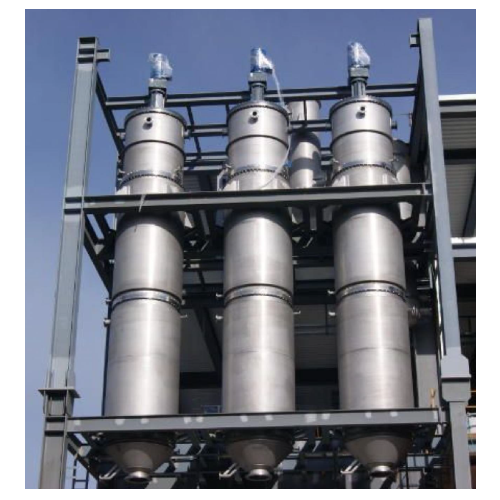

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

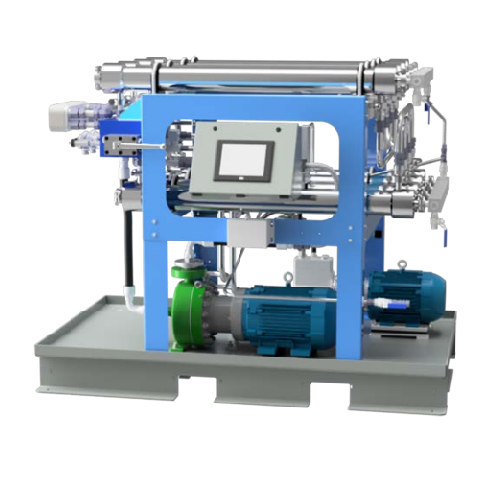

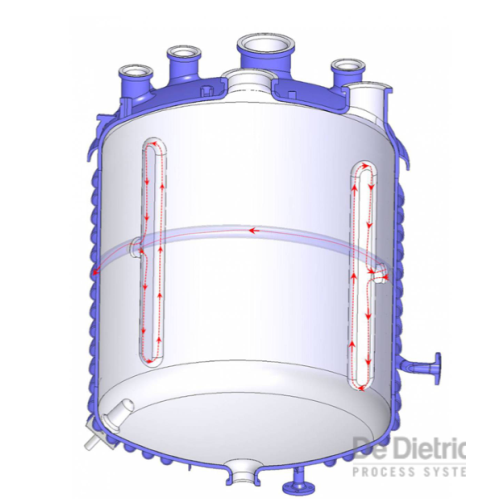

Winterization reactor for botanical extraction

Achieve precise temperature control and efficient separation during winteri...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Stories about plant extracts

Two steps to stop formula deviation in CBD Gummies

#Changemaker: Fava bean umami extract for your vegan diet!

#Changemaker: A divine alternative to synthetic preservatives

#Changemaker: Discovering the Rooibos plant applications

The careful drying of herbal medicine

CBD oil production to achieve a new 'high'

Select your plant extracts process

Tell us about your production challenge

Plant extraction equipment relies on heat treatment

Conventional extraction processes such as maceration, decoction, infusion, digestion, percolation, and hydrodistillation remain effective. But advanced techniques such as ultrasound-assisted extraction and microwave-assisted extraction reduce the heat impact on the target compounds.

An alternative technique uses the solvent extraction method, such as ethanol and C02, to dissolve the plant material and absorb the oils. The solvent is then evaporated, releasing the plant extract. Depending on the type of solvent used, high or low temperatures raise the levels of solubility and diffusion, but excessive heat risks perishing thermolabile components.

Set drying temperatures to between 40°C and 50°C

Place the plant in an oven with a temperature range above 40°C but not exceeding 50°C. In the case of delicate plants, freeze-drying protects the thermolabile compounds. Set drying temperatures to between -60°C and -80°C

Drying the materials before they are processed by plant extraction machines preserves them from enzymatic degradation.

Plant extract applications in the animal care sector

In addition to featuring prominently in the pharmaceutical, cosmetic, and food industries, plant extracts are useful for animal care. Extracts derived from various plants are effective at destroying parasites that target pets and livestock.

In fact, several plants contain natural active ingredients such as geraniol and eugenol that are deadly to pests. These chemical compounds in these plants are effective against parasites.

Plant extraction technology oriented towards active packaging

Plant extracts can be applied to Active Packaging solutions. This novel procedure incorporates antimicrobial compounds in the plants in packaging film solutions.

The hydrophobicity of essential oils forms a boundary wall to minimize the migration of water vapor through the film. Meanwhile, the natural antioxidative properties in plant extracts add a protective layer to the packed products.

Which plant extracts technology do you need?

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Color remediation column for cannabis extracts

Ensure the purity of your cannabis extracts by efficiently removing contami...

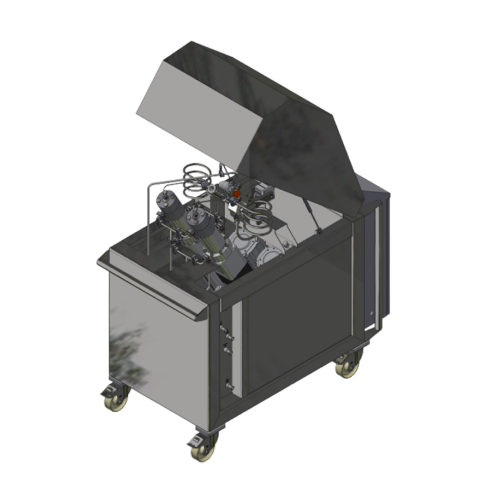

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Solid/liquid extraction system for industrial applications

Optimize your solid-liquid extraction needs with a compact mu...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Winterization reactor for botanical extraction

Achieve precise temperature control and efficient separation during winteri...

Ice water extraction system for solventless extract production

Optimize your plant-based extraction processes with a mod...

Pectin extraction decanter centrifuge

Achieve precise separation and maximize yield in pectin and plant extract processing ...

Cannabis distillation system for high-potency extracts

Ensure your extracts achieve up to 99% cannabinoid purity with pre...

Hydrocarbon extraction equipment for cannabis and hemp processing

Optimize your extraction processes with a high-capaci...

Advanced rosin press for solventless extraction

Enhance your extraction capabilities with precision-controlled pressure an...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Ultrasonic barbell for extraction

Conventional extraction methods are time-consuming, labour-intensive and can sometimes be...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

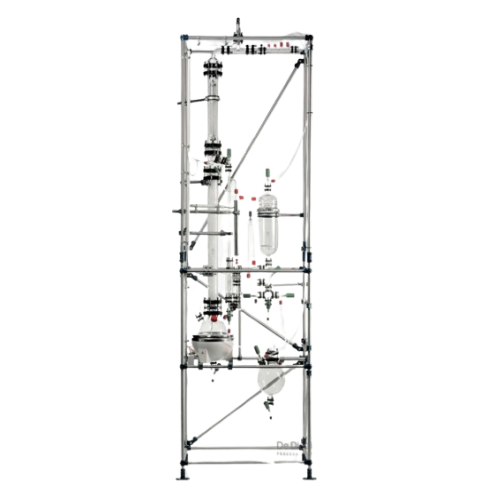

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

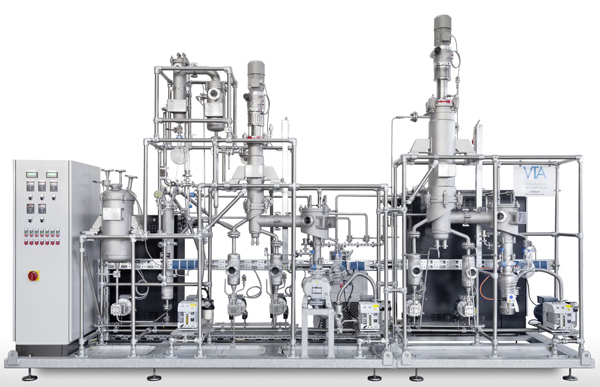

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

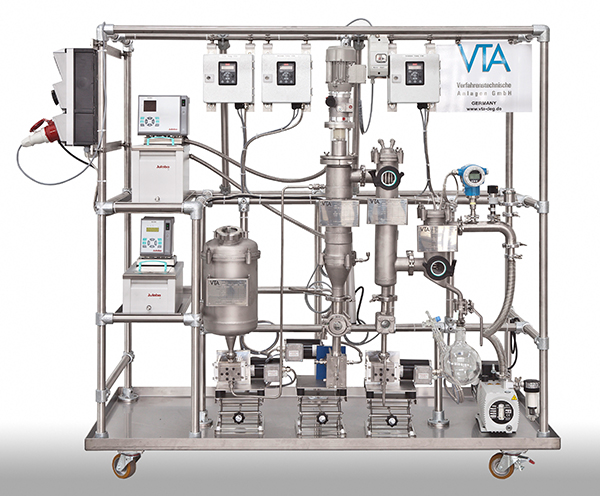

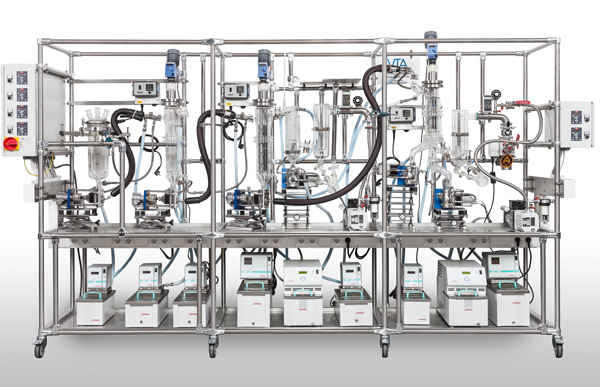

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

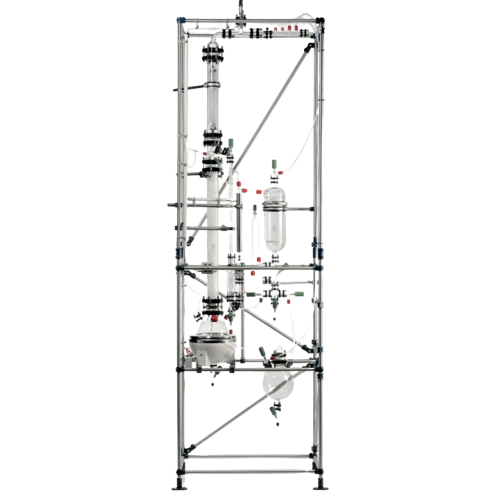

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuri...

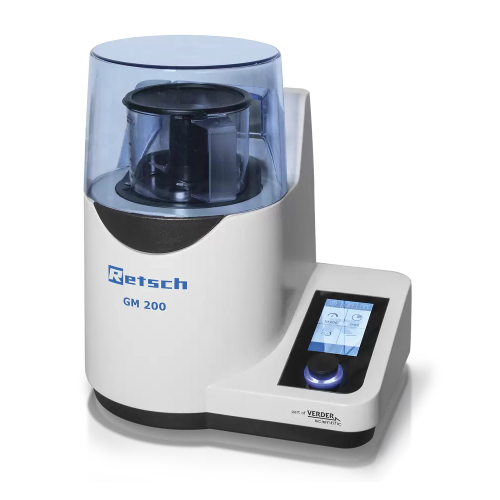

Laboratory mixer mill for small volume grinding

Designed for rapid homogenization and size reduction, this versatile mixer...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Heating mantle system for round bottom glassware

Optimize your lab’s heating and stirring processes with a snug-fit system...

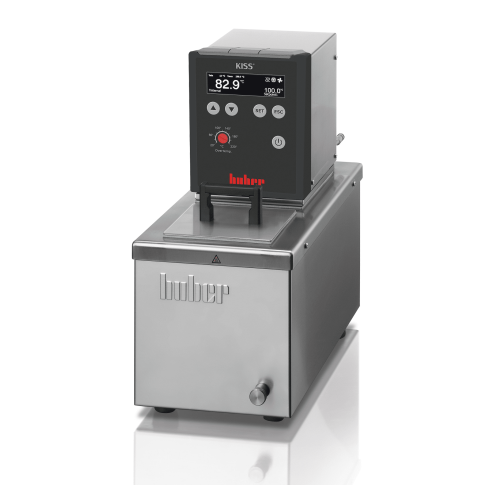

Heated circulator for laboratory temperature control

Achieve precise temperature control for demanding applications like ...

Moisture analyzer for precise and reliable measurements

Ensure precise moisture control in high-value products like lyoph...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

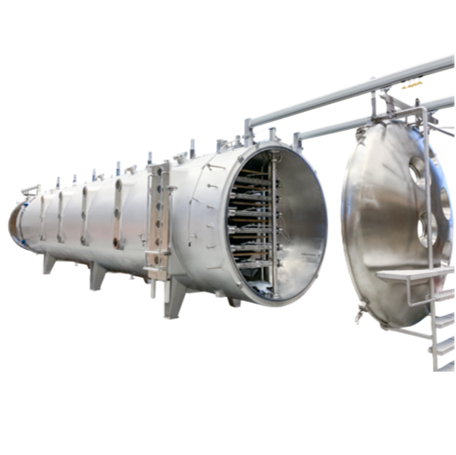

Vacuum and freeze drying plants for food and pharmaceuticals

Ensure high-quality, extended shelf-life products with inno...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

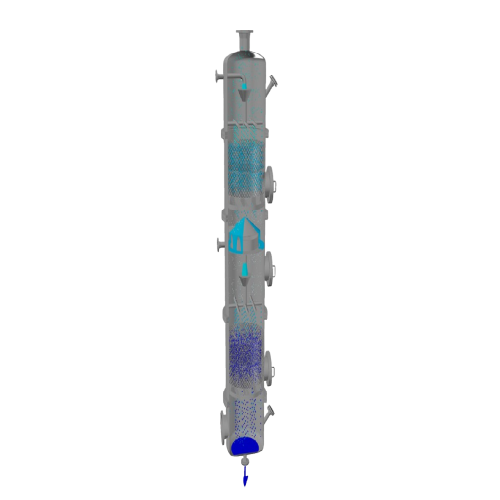

Falling film evaporator for botanical oil separation

Optimize your ethanol recovery and botanical oil production with hig...

Microwave-enhanced filter dryer for chemical and pharmaceutical applications

Achieve rapid drying and efficient separa...

Condensation and separation unit for solvent handling

Enhance solvent management and VOC recovery with this compact conde...

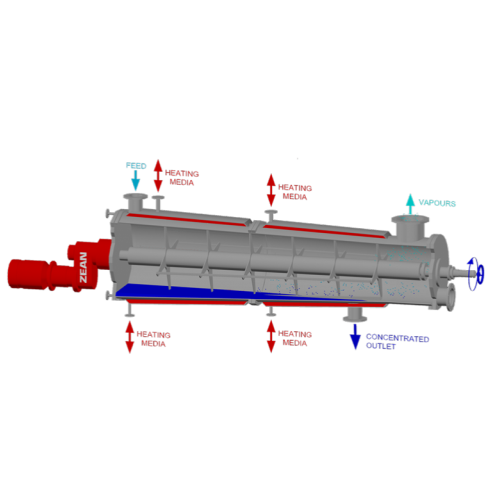

Horizontal thin film evaporator for continuous distillation

Experience precise control over evaporation and distillation...

Cross-flow filtration unit for clarifying juice and wine

Achieve optimal clarity and yield with this semicontinuous cross...

High-speed tubular centrifuges for liquid-solid separation

For efficient component separation in high-viscosity fluids, ...

High-throughput vacuum evaporator for laboratory applications

Achieve precise solvent removal and efficient sample handl...

300l stainless steel dual-jacketed reactor for winterization

Enhance your extract processing with precision temperature ...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

Nanofiltration system for dairy and plant-based applications

Enhance your production capacity with nanofiltration, ensur...

Benchtop freeze dryer for laboratory research

Streamline your lab’s freeze-drying processes with precision temperatu...

Industrial seaweed drum dryer

Optimize your seaweed and algae processing with an advanced drum drying solution that effectiv...

Cannabis distillate production system

Achieve high-purity cannabinoid distillates with continuous, high-volume processing t...

Cannabis and hemp processing nanofiltration system

Enhance the clarity and potency of your extracts with advanced membran...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Automatic centrifuge for cannabis

Centrifugation is an effective method for producing cannabis extracts. The extraction pro...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Xrd sample preparation mill for geology and materials science

Achieve precise particle size distribution and preserve cr...

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Mobile fluid bed dryer for small seed lots

Dry your small seed lots efficiently and flexibly with a mobile fluid bed dryer...

Flexible seed rinsing and treatment station

For seed producers needing precise, controlled treatment, this rinsing station...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increas...

Thin film evaporator for temperature sensitive products

Need to purify temperature-sensitive compounds efficiently? Achie...

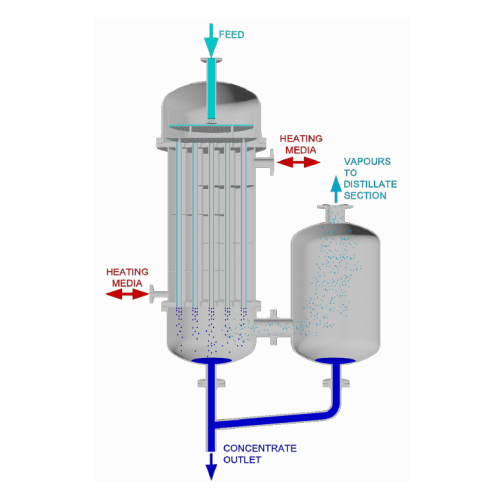

Falling film evaporator for thermal separation

Optimize energy efficiency in separation processes by utilizing gravity-dri...

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds wit...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Industrial rotary evaporator for distillation

Optimize your distillation efficiency with a solution designed for precise c...

Agitated nutsche filter dryer for solid-liquid separation

Achieve high-purity solid-liquid separation with optimized thr...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Benchtop freeze dryer for laboratory and small production use

Optimize your lab’s efficiency by adding precise, space-sa...

Laboratory freeze dryer for peptide production

Achieve precise moisture removal and stability with a versatile freeze-dryi...

Pilot freeze dryer for research and small-scale production

Optimize moisture removal and sample preservation with this v...

Sterilizer for finished liquid products

Ensure precise thermal control and asepsis in your liquid product sterilization pro...

Pharmaceutical freeze dryer for medium scale production

Ensure optimal preservation of active ingredients through precise...

2l single jacketed glass reactor system

Enhance your laboratory’s efficiency with a versatile reactor system, ideal f...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Chromatography systems for large-scale biopharmaceutical purification

Ensure precision purification of biopharmaceutica...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Ultrafiltration for dairy and plant-based protein concentration

Optimize your production capacity and increase yield wit...

Spray bed dryer for agglomerated powder production

Efficiently transform liquid feedstock into consistent, dust-free powd...

Pilot freeze dryer for laboratory and small-scale production

Achieve precise temperature and vacuum control for consiste...

Laboratory freeze dryer

Achieve precise moisture control and enhanced product stability with this advanced freeze-drying solu...

Seaweed cultivation vectorizing solution

Streamline your seaweed cultivation process with precise vectorization, reducing m...

Industrial vacuum batch dryer for reducing moisture content

Achieve precise moisture control with a solution that handle...

Cannabis and hemp short path distillation system

Achieve optimal cannabinoid purification with continuous high-volume dist...

R&D bottle washer

When you pack your products in bottles, vials, syringes, and test tubes you need to wash them before fillin...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

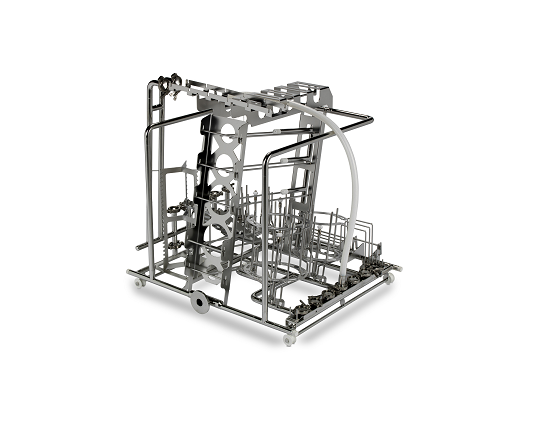

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

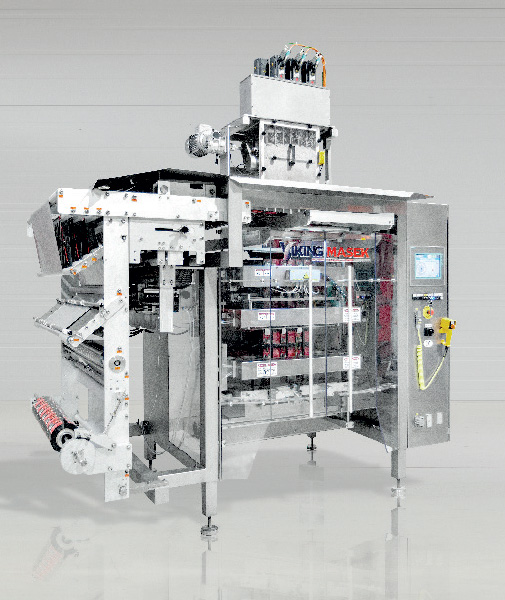

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...