Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuring precise removal of impurities and enhancing product yield across diverse biochemical applications.

Separates and Clarifies Biochemical Mixtures

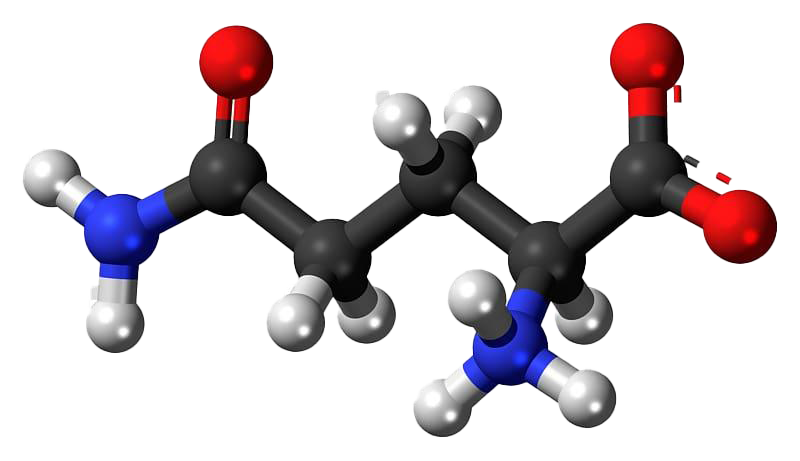

The GEA clarifier for biochemicals is engineered to precisely separate and clarify complex mixtures in industries like pharmaceuticals, biotech, and food processing. Employing a disk-type bowl with a movable sliding piston, it facilitates rapid and gentle separation, ideal for high-purity amino acids, vitamin extracts, and bioethanol production.

Suitable for continuous operations, the clarifier features a centripetal pump for foam-free liquid discharge and a precise ejection system for uninterrupted performance. With customization options based on customer lab tests, the equipment seamlessly integrates with existing production lines, enhancing process efficiency.

Available in corrosion-resistant materials, this clarifier meets stringent industry standards, including those required for pharmaceutical compliance, ensuring both safety and extended equipment lifespan. Its design also supports easy maintenance, minimizing downtime with features such as CIP systems for efficient in-line cleaning.

Benefits

- Ensures high product purity with continuous, precise separation processes.

- Minimizes operational costs with efficient energy use and reduced waste.

- Compliant with stringent industry standards for safety and quality.

- Integrates seamlessly into existing systems, enhancing production efficiency.

- Offers customizable configurations to meet specific application needs.

- Applications

- Food, Personal care, Marine, Gas, Energy, Beverage, White biotechnology, Oil, Chemical, Environment, Biochemicals, Home, Dairy, Pharmaceuticals

- End products

- Amino acids, Fermentation broths, Milk proteins, Bioethanol, Marine bioactives, Wastewater sludge, Plant extracts, Wastewater treatment residues, Essential oils, Biodiesel, Algae extracts, Lactose, Fruit juices, Vitamin extracts

- Steps before

- Fermentation, Preparation, Mixing, Chemical Reaction

- Steps after

- Storage, Quality Control, Packaging, Distribution

- Input ingredients

- biochemicals, white biotech products

- Output ingredients

- clarified liquid, ejected solids, high product quality

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Bowl Type

- Disk-type

- Automation

- PLC-controlled

- Liquid Discharge

- Foam-free, under pressure

- Efficiency

- High efficiency

- Operation Type

- Continuous

- Solids Ejection

- Precise ejection at operating speed

- Pressure Discharge

- Centripetal pump

- Customization

- Designed after laboratory tests

- Sliding Piston

- Movable

- Working mechanism

- Disk-type bowl, movable sliding piston

- Separation process

- Fast, gentle, high efficiency

- Liquid discharge

- Foam-free, under pressure via centripetal pump

- Operation mode

- Fully continuous

- Solids ejection system

- Precise ejection at operating speed

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Disk-type bowl

- Movable sliding piston

- Discharge method

- Foam-free, under pressure via centripetal pump

- Discharge method

- Centripetal pump

- Compact footprint

- Customizable

- Discharge pressure

- Foam-free discharge