Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for developing precise flavors and bioactive compounds.

Extracts Active Ingredients from Solid Materials

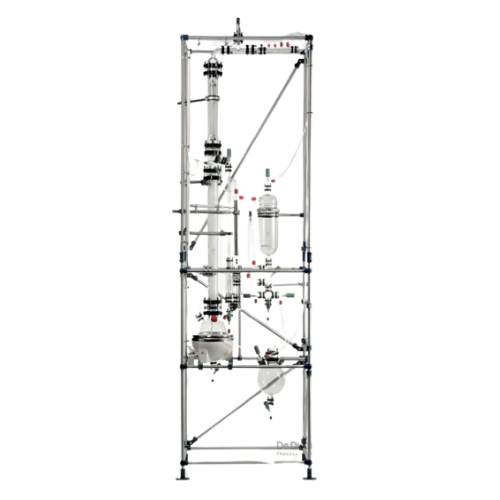

The Solid/Liquid Extraction Unit by De Dietrich Process Systems is tailored for intensive research and development applications. This versatile system optimizes extraction of active ingredients from solid matrices, making it invaluable for fine chemical production, pharmaceuticals, and plant-based ingredient processing. It offers continuous downward and overflow extraction modes, along with Soxhlet extraction for comprehensive trials. The system’s 4-liter borosilicate glass extraction vessel, complemented by a distillation column and spherical distillation vessel, enables precise solvent recovery and ingredient concentration. Electrically heated for efficiency, it supports detailed process monitoring through optional instrumentation and control systems. Ideal for industry-standard practices, the unit integrates seamlessly into pilot or continuous setups, ensuring consistent results while enhancing energy efficiency. Available in corrosion-resistant materials, it meets rigorous operational demands, providing compliance and robust performance in diverse chemical environments.

Benefits

- Enhances extraction precision, ensuring high-quality yield of active ingredients.

- Supports energy efficiency with optimized heating elements.

- Facilitates easy raw material replacement with quick-access vessel design.

- Adaptable to diverse extraction methods, offering flexibility in process development.

- Constructed from durable borosilicate glass, ensuring long-term chemical resistance.

- Applications

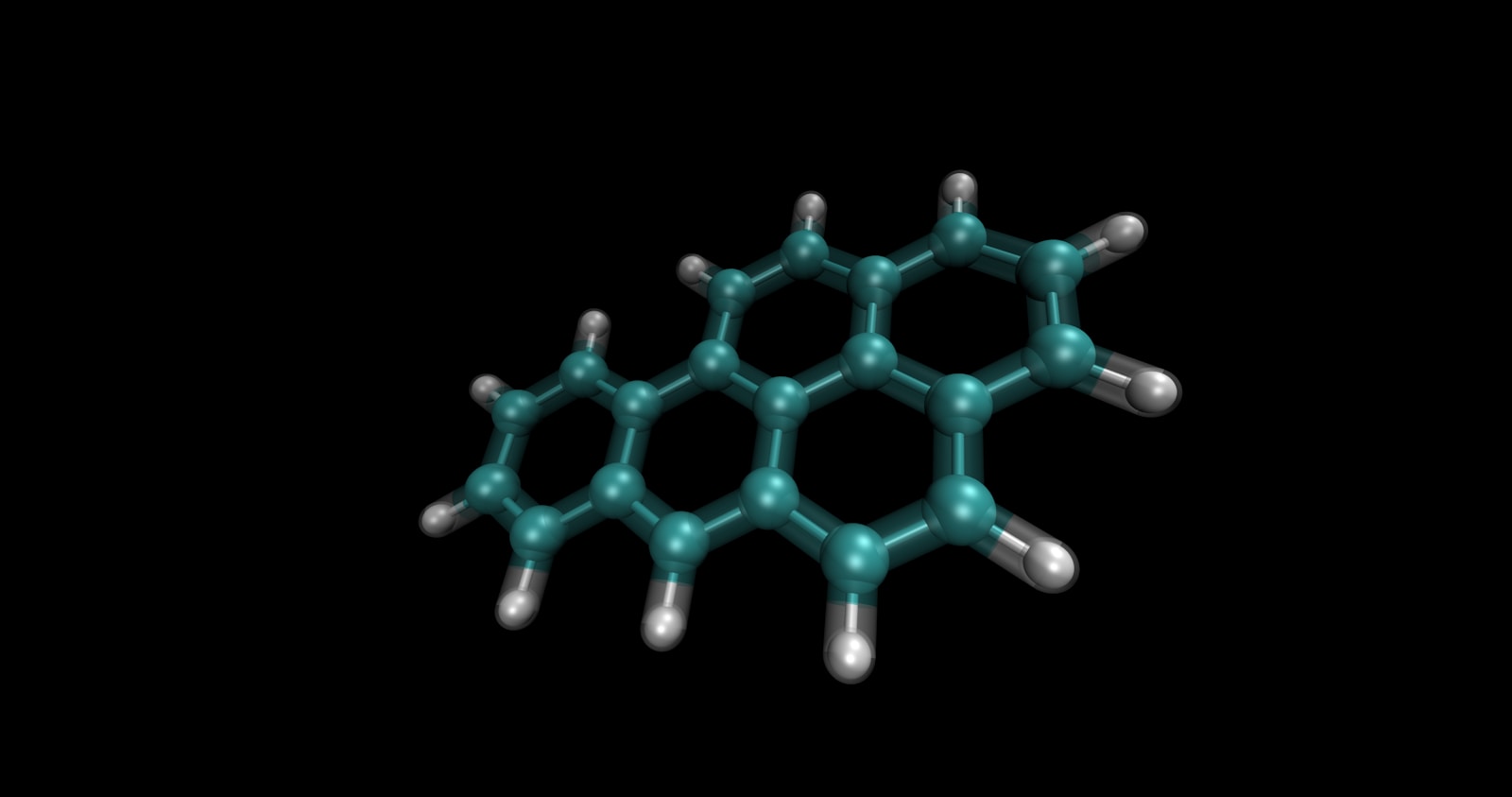

- Specialty chemicals, Fine chemicals, Pharmaceuticals, Flavors and fragrances, Plant-based ingredients, Bio-pharmaceuticals, Essential oils

- End products

- Active pharmaceutical ingredients (apis), Bioactive compounds, Plant extracts, Flavor concentrates, Specialty chemical compounds, Herbal supplements, Fragrance oils, Botanical tinctures

- Steps before

- Grinding, Drying, Emulsification, Purification

- Steps after

- Concentration, Distillation, Cooling, Sampling

- Input ingredients

- solid raw material, agricultural product, flavor, active ingredient, solvent

- Output ingredients

- extracted flavor, extracted agents, concentrated ingredients

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Extraction vessel size

- DN 150, 4 Liters

- Distillation vessel size

- 6 Liter spherical vessel

- Column size

- DN 80, glass packing

- Receiver size

- 6 Liter spherical vessel

- Condenser area

- 0.3 m² coil heat exchanger

- Distillate cooler area

- 0.03 m² coil heat exchanger

- Heating power

- 1700 W, 230V

- Pre-heater power

- 300 W, 230V

- Material

- Borosilicate glass or PTFE

- Structure material

- Stainless steel

- Dimensions

- 1000 x 600 x 3300 mm

- Working mechanism

- Continuous / Batch

- Integrated steps

- Extraction / Distillation

- Operating temperature

- Adjustable based on raw material

- Solvent handling

- Preheated / Cooled

- Automation level

- Optional manual / PLC control

- Quick changeover design

- Easy raw material replacement

- Energy usage for extraction method

- Comparison of energy input for different methods

- Method versatility

- SOXHLET, Continuous downward, Continuous overflow

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- 1000 x 600 x 3300 mm

- Basket Material

- Borosilicate Glass

- Extraction Vessel Size

- DN 150, 4 Liters

- Distillation Vessel Size

- 6 Liter spherical vessel

- Column Size

- DN 80

- Condenser Surface Area

- 0.3 m² coil heat exchanger

- Distillate Cooler Surface Area

- 0.03 m² coil heat exchanger

- Piping Material

- Borosilicate Glass or PTFE

- Control panel type

- Optional control cabinet and process control system

- Integration options

- Suits continuous or batch operations

- Material of construction

- Piping and valves made from borosilicate glass or PTFE, stainless steel structure

- Operation method

- Optional continuous downward or overflow extraction

- Heating options

- Electrical heating for distillation

- Extraction method

- Continuous downward, overflow, or SOXHLET-Extraction