Bio-pharmaceuticals

Find innovative production technology for making bio-pharmaceuticals and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in bio-pharmaceuticals making

Which bio-pharmaceuticals technology do you need?

Powder blender for efficient mixing and discharge

Achieve precise mixing and efficient discharge with advanced powder ble...

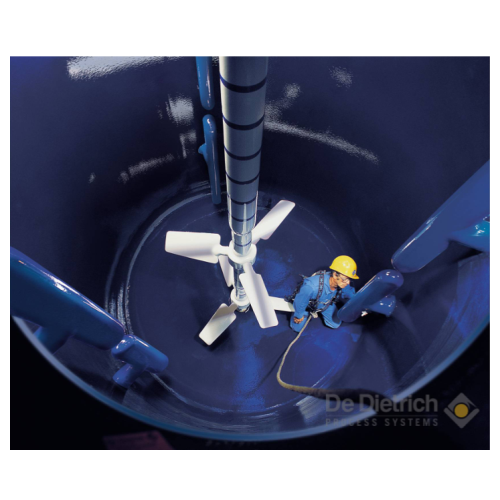

Glass-lined reactor for enhanced mixing performance

Optimize your chemical processes with a reactor that enhances mixing ...

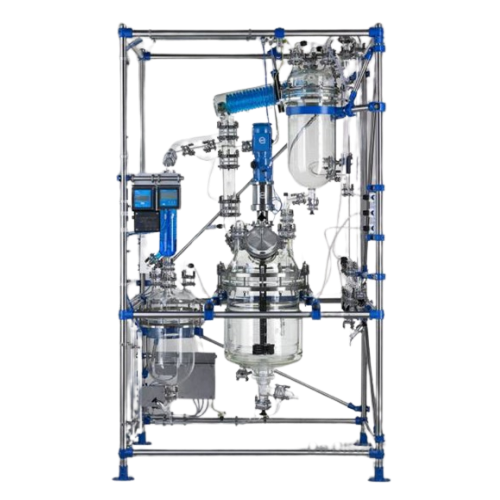

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, t...

Vacuum drying for heat-sensitive products

Ensure moisture-sensitive formulations are dried efficiently without compromisin...

Heat exchanger for corrosive substance handling

Optimize your process of handling corrosive substances with a heat exchang...

Corrosion-resistant shell and tube heat exchangers for pharmaceuticals

Ensure efficient thermal management in high-puri...

Pilot scale filter-dryer for pharmaceutical and chemical batches

Streamline small-batch production with a mobile filter-...

Static nutsche filters for liquid-solid separation

Achieve efficient separation of solids from liquids with precise contr...

Liquid/liquid extraction mixer-settler plant

Optimize your extraction processes with a highly efficient mixer-settler syst...

12l solid/liquid extractor for pilot plant solutions

Optimize your extraction processes with a versatile extractor that a...

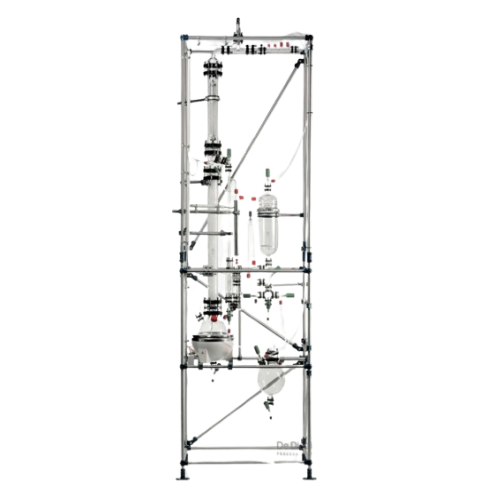

Solid/liquid extraction unit for process development

Optimize your extraction processes with flexible operation modes for...

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

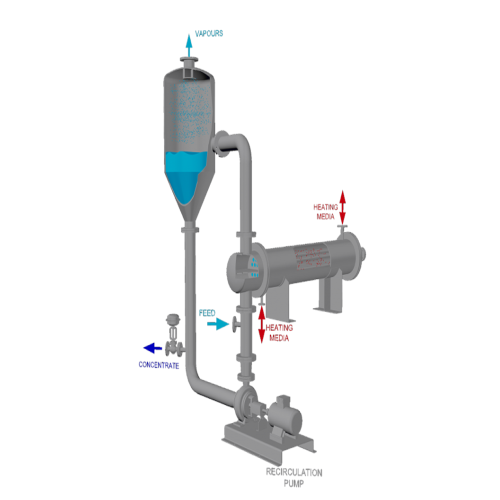

Force circulation evaporator for high viscous products

Optimize energy efficiency and manage challenging liquid compositi...

Low-temperature screw compressor for industrial refrigeration

Optimize your refrigeration system with this high-capacity...