Force circulation evaporator for high viscous products

Optimize energy efficiency and manage challenging liquid compositions with a system designed for high-capacity evaporation, ensuring seamless integration into your continuous production line.

Evaporates and Separates High-Viscosity Fluids

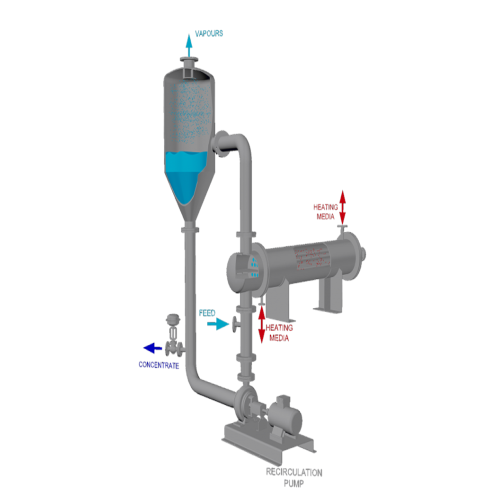

The Force Circulation Evaporator from De Dietrich Process Systems is engineered to optimize the handling of high-viscosity and solid-laden products in chemical and pharmaceutical industries. This robust evaporator employs a recirculation principle, ensuring superior heat transfer and effective separation in demanding conditions. It excels in applications such as solvent recovery, Active Pharmaceutical Ingredients (API) concentration, and specialty polymer processing. Designed for continuous, high-capacity, multi-effect evaporation and vapor recompression, this equipment significantly conserves energy. Available in various materials to resist corrosion and tailored to meet specific process requirements, it integrates seamlessly into existing production lines. Automated PLC controls and remote monitoring ensure precision and ease of operation, while its compliance with industry standards guarantees quality and reliability. Additionally, the system’s ease of cleaning and maintenance, supported by full engineering customization, ensures minimal downtime and optimal performance in any production environment.

Benefits

- Enhances productivity with efficient handling of high-viscosity and solid-laden liquids.

- Reduces energy costs through multi-effect evaporation and vapor recompression.

- Minimizes downtime with seamless integration and automated PLC control.

- Offers versatility with material options for diverse chemical compatibility.

- Ensures quality and compliance with industry standards for pharmaceutical and chemical applications.

- Applications

- Green chemistry, Waste water treatment, Specialty chemicals, Agricultural chemicals, Fine chemicals, Plant-based ingredients, Bio-pharmaceuticals, Pigments, Pharmaceuticals

- End products

- Biologics, Flavonoid extracts, Active pharmaceutical ingredients (apis), Food colorants, Solvents, Bio-based solvents, Reclaimed water, Fertilizers, Specialty polymers

- Steps before

- Liquid-Solid separation, Extraction, Membrane Technology, Neutralisation, Heating

- Steps after

- Condensation, Purification, Distillation, Drying

- Input ingredients

- feed liquid, solid content, highly viscous products

- Output ingredients

- evaporated low boilers, superheated product

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Evaporation Rate

- High

- Heat Transmission Coefficient

- High global

- Viscosity Handling

- High viscous products

- Arrangement

- Horizontal available

- Recirculation System

- Yes

- Working mechanism

- Forced circulation with heat exchanger and flash vessel

- Recirculation efficiency

- High global heat transmission coefficient

- Product handling

- Solid content or high viscous products

- Energy conservation

- Multiple effect evaporation or vapor recompression

- Flow configuration

- Horizontal arrangement capability

- Solid content

- Yes

- Multiple effect evaporation

- Suitable

- Vapor recompression

- Suitable

- Feed method

- Recirculation stage

- Discharge method

- Flash vessel

- Size

- Horizontal arrangement

- Shape

- Flash vessel

- Tank design

- Recirculation capable

- Material flow

- Solid and highly viscous

- Heat exchanger type

- Customizable to operation needs

- Horizontal arrangement

- Optional