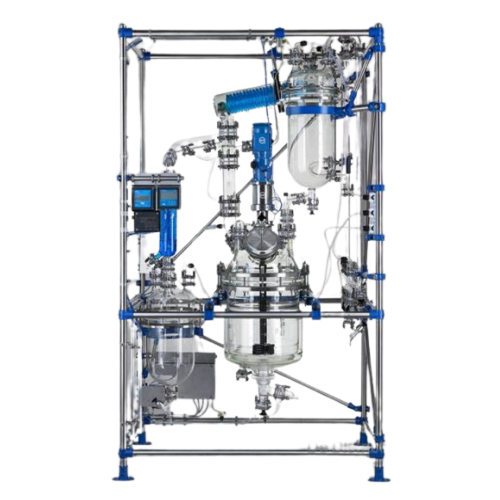

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, this versatile reactor safely handles large-batch reactions under a broad range of temperatures and pressures, ensuring precise control and efficient processing of complex formulas.

Synthesizes, Distills, and Mixes Large-Scale Chemical Reactions

The QVF Universal-Reactor from De Dietrich Process Systems is your go-to solution for scaling up chemical reactions that exceed lab-scale capabilities. Designed for the pharmaceutical, fine chemicals, and specialty chemicals sectors, it allows for precise control in synthesizing active pharmaceutical ingredients, monoclonal antibodies, specialty polymers, and more. By employing a versatile, inert gas-compatible design, this reactor excels in handling liquid and gas processes under vacuum and EX-rated conditions. It facilitates seamless integration into existing lines with its robust, digitally controlled stirrer and OptiMix® baffle system, offering extraordinary mixing performance without splashing. Featuring a borosilicate glass construction and PTFE components, it ensures optimal chemical resistance and longevity. The reactor is equipped with CIP-nozzles, ensuring easy and reliable cleaning between batches, thus minimizing downtime. Compliance with European EX regulations guarantees safe operation in volatile environments. Whether for pilot studies or full-scale production, you can request custom configurations to best meet your specific operational needs.

Benefits

- Enhances scalability for production beyond lab capabilities, supporting larger batch sizes.

- Ensures safety in volatile environments with EX-rated design and materials.

- Reduces downtime with efficient cleaning via CIP system.

- Optimizes reaction control with precise temperature and mixing adjustments.

- Maintains chemical integrity with corrosion-resistant borosilicate glass and PTFE construction.

- Applications

- Specialty chemicals, Agricultural chemicals, Fine chemicals, Bio-pharmaceuticals, Precious metal, Pharmaceuticals

- End products

- Active pharmaceutical ingredients (apis), Agrochemicals, Monoclonal antibodies, Specialty polymers, High-purity gold, Catalyst complexes, Platinum group metal compounds

- Steps before

- Mixing, Reactant Addition, Vacuum Application, Inert Gas Preparation, Jacketed Vessel Tempering

- Steps after

- Distillation, Temperature Control, Vacuum Distillation, Product Transfer, Cleaning via CIP-Nozzles

- Input ingredients

- reactants, inert gas, light boiling components, thermo liquids

- Output ingredients

- light boiling components, distillate receiver, solvents, temperature sensitive products

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Temperature Range

- -50°C to 200°C

- Operating Pressure

- up to +0.5 barg

- Material

- Borosilicate Glass 3.3

- Stirrer Drive

- Electric motor with adjustable gearbox

- Cleaning Method

- CIP via CIP-nozzles

- Distillation Capability

- Light boiling components

- Automation

- Manual adjustment

- Working Mechanism

- Batch synthesis with inert gas

- Temperature Range

- -20°C to +150°C

- Pressure Control

- Inert gas overpressure up to +0.5barg

- Vacuum Operation

- Yes, with vacuum and overpressure operation

- Cleaning Method

- CIP with self-draining construction

- Mixing Performance

- OptiMix® baffle system

- Distillation Capability

- Light boiling component distillation

- Automation Level

- EX-rated instrumentation for automated operation

- Heating/Cooling Integration

- Jacketed vessel with a thermo liquid

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact

- Reactor Shape

- Jacketed Vessel

- Reactor Size

- Customizable

- Discharge Method

- Distillation/Withdrawal

- Feed Method

- Handhole and Vacuum Feed

- Construction Material

- Borosilicate Glass 3.3

- Stirrer Drive

- Robust Electric Motor

- Temperature Control

- Thermo Liquids

- Pressure Control

- Max +0.5barg

- Seal Type

- Single Mechanical Seal

- Cleanability

- CIP Nozzles

- Baffle System

- OptiMix® Baffles

- OptiMix Baffles

- Triple-walled reactor

- Vacuum connection

- Including pressure release valve and bursting disc

- CIP-Nozzle

- Made of PTFE or stainless steel