Containment Technology

Find innovative containment equipment and connect directly with world-leading technology suppliers

The essential objectives of containment systems are personnel protection and preventing the release of toxic or infectious material into the environment. Containment is also used to prevent a product or sample from contamination by the external environment. In the chemical and pharmaceutical industries, containment solutions are used to protect the personnel from the leaking of airborne particles of hazardous substances, as powders or liquids are handled or transferred during processing.

As industrial processes and products become more complex, the need for effective containment technology and equipment is increasing. In response to this, the market for containment has expanded to include a range of solutions that cater to specific needs and applications. From glove boxes and fume hoods to spill kits and new products and innovations. Containment equipment are also essential for preventing potentially hazardous spills and leaks. Spill kits are a critical component of any industrial facility, warehouse, or lab. These kits include materials and tools for quickly containing and cleaning up spills. Such as chemicals, oils, powders and liquids.

What are you making?

Active pharmaceutical ingredients (API)

Ampoules

Cytotoxic drugs

Enteric Coated Tablets

Feed concentrates

High-potency active pharmaceutical ingredients (hpapis)

High potent drugs

Highly Active Pharmaceutical Ingredients

Insulin

Microtablets

Nuclear

Oil sludge

Parenterals

Pharmaceutical cartridges

Pre-filled Syringes

Vaccines

Vials

Water for injection

Airlocks

Aseptic isolators

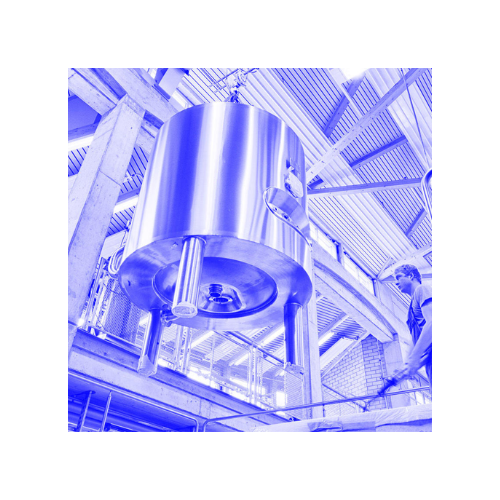

Asme pressure vessels

Barrier systems

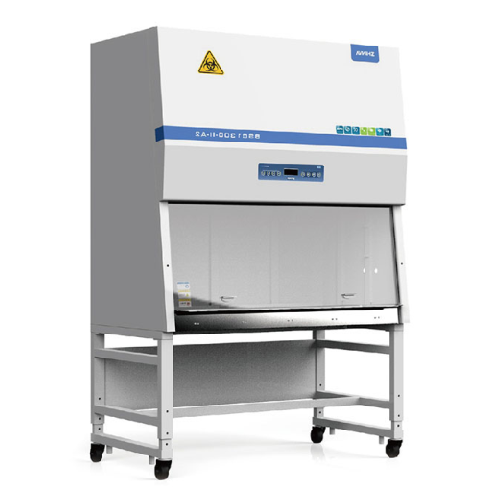

Biological safety cabinets

Biosafety barrier solutions

Biosafety cabinets

Contained transfer systems

Containment isolators

Decontamination transfer air locks

Dispersion containers

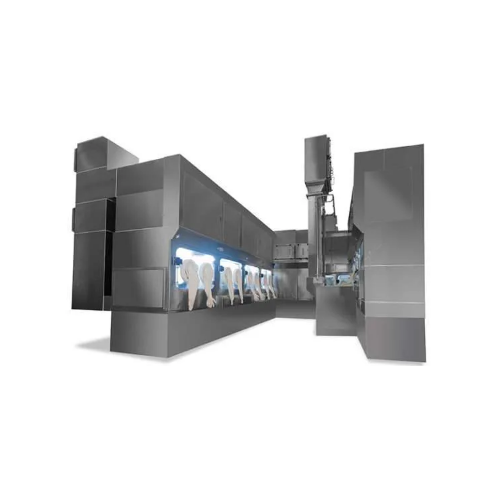

Downflow booths

Flexible containment solutions

Glove boxes

Hoists for vacuum conveyors

Steam chambers

Sterility test isolators

Vacuum chambers

Which containment technology do you need?

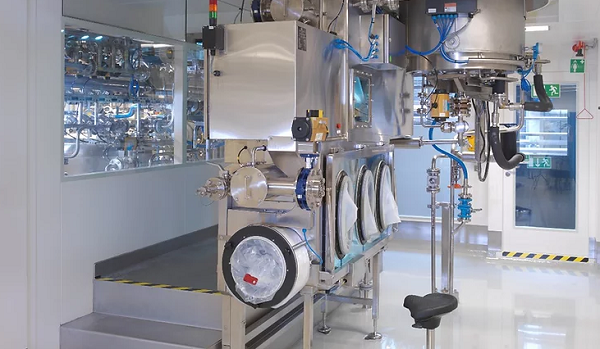

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

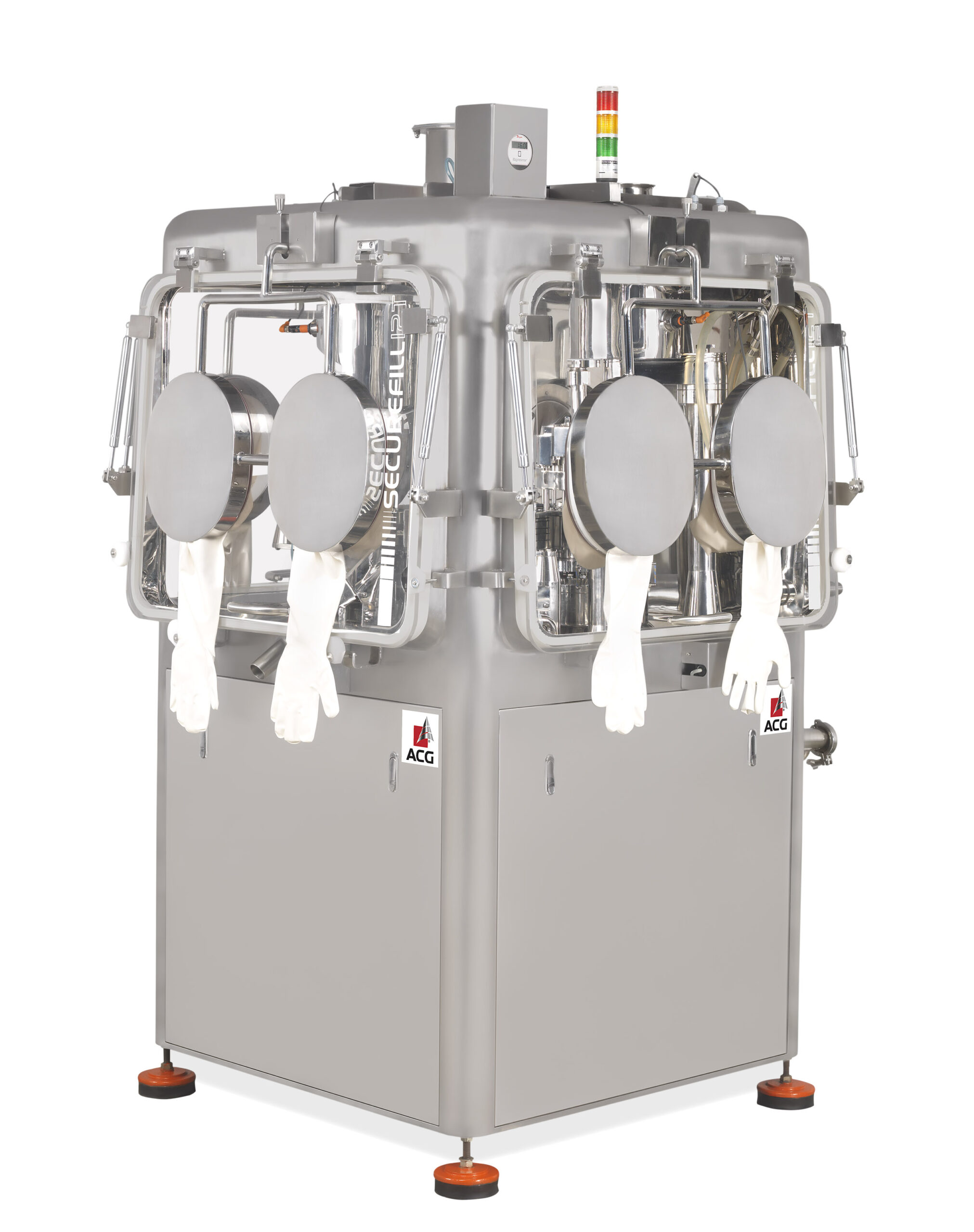

Tablet press for high containment environments

For handling potent compounds without compromising safety, a high-containme...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Containment solutions for pharmaceutical production

Enhance operator safety and product integrity with advanced containme...

Powder conditioning station for high containment applications

Ensure safe and precise handling of hazardous powders with...

High containment isolator for wet analysis in pharma

Achieve high containment and precise wet analysis with this isolator...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

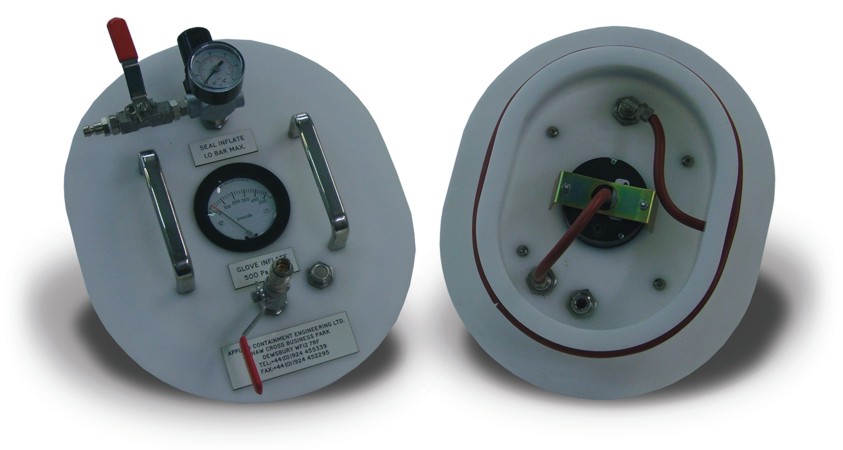

Active Gmp plug for valve containment

Ensure the integrity and safety of your valve system by preventing contamination and ...

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

Sterilisable isolator workstation for aseptic containment

Ensure precise contamination control and sterile conditions du...

High containment isolator for toxic and active drug handling

Ensure safe handling and environmental protection while pro...

Stainless steel pharma bin for powder containment

Ensure precise powder handling and containment with this stainless stee...

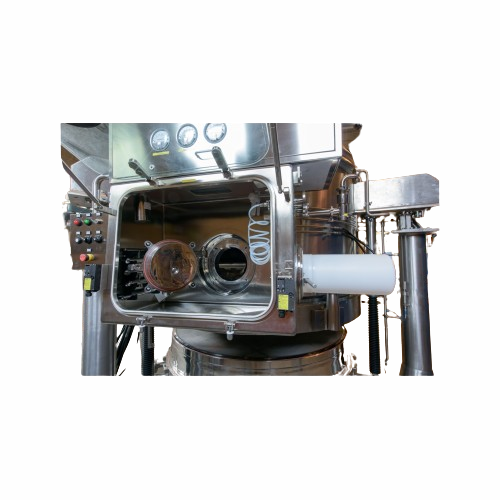

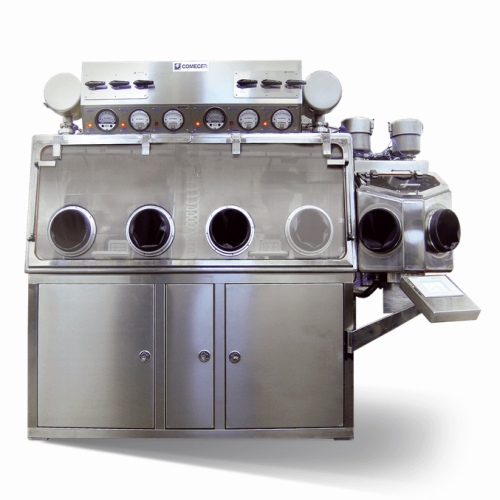

Containment tablet coater for high-potency drugs

Ensure operator safety while achieving precise tablet coating on high-pot...

Containment tablet coater for high-potency pharmaceuticals

Ensure operator safety and maintain stringent OEB 4 complianc...

Containment capsule filler for highly potent drugs

Achieve complete operator safety while encapsulating potent pharmaceut...

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-poten...

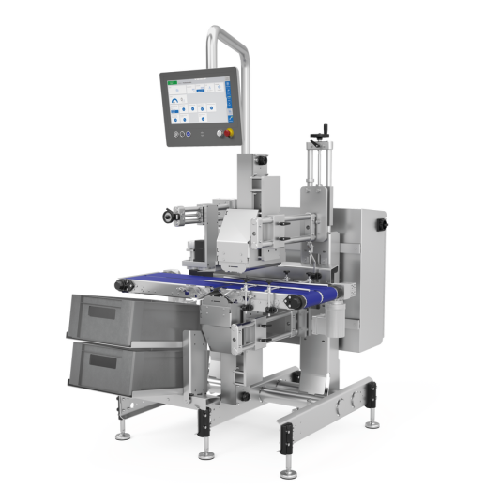

Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent...

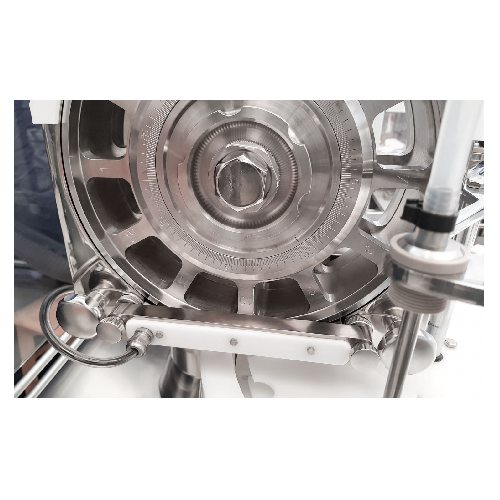

Tablet compression module for high containment applications

Quickly switch between tablet batches without compromising s...

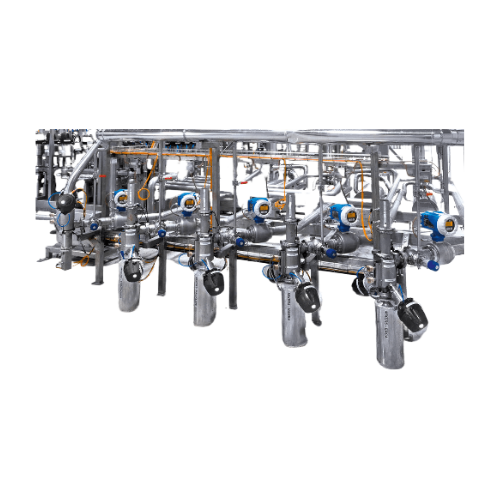

Containment valves for pharmaceutical powder transfer

Ensure safe transfer of highly potent pharmaceuticals with this mod...

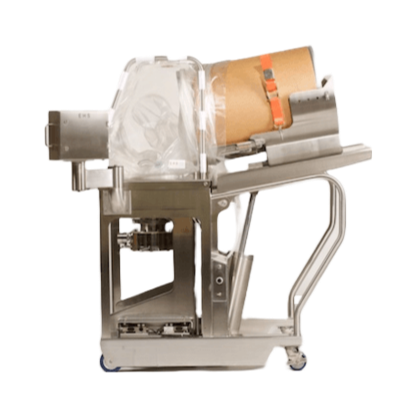

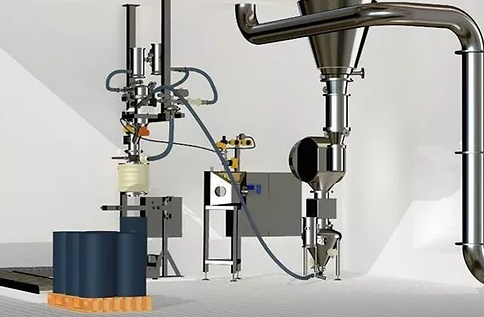

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Containment single-use filter module

Ensure safe handling of high-potency substances and streamline filtration processes wi...

Containment isolators for pharmaceutical and biotech applications

Ensure operator safety and product integrity during t...

Microbiological safety cabinet for laboratory containment

Ensure seamless microbiological containment and operator prote...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

High containment big bag discharge docking system

The discharge of materials demands strict containment, particularly in ...

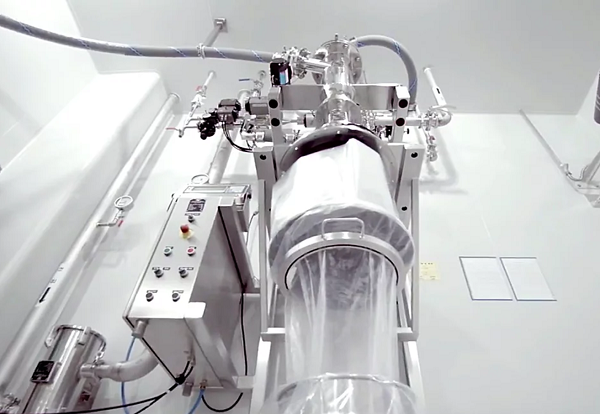

High containment micronizing isolator

Powder processing for chemical compounds demands product-specific micronizing solutio...

API containment isolator

Contamination is a major concern in powder handling, not least when processing pharmaceutical produc...

Single-use containment valve

Safe transfer of liquids and hazardous powders into systems can be a challenge in pharma, bioph...

High containment closing system

Pharma and biopharma laboratories need fast effective solutions for tightly sealing bags for...

High containment sampler

Drawing a sample for evaluation from a running process is not a simple task, especially when dealing...

Flexible containment docking solution

When sampling or transferring hazardous substances and sensitive bulk goods, a dust-t...

Flexible containment zip

Transfer of sensitive and toxic bulk goods across process units requires specialist handling to prev...

Transfer system for high-containment environments

A high-performance transfer port system that combines ultimate safety, ...

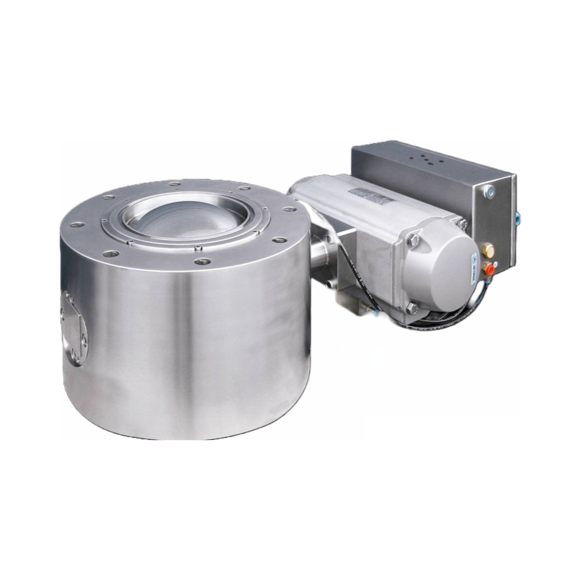

High containment split butterfly valve

Powder containment is the cornerstone of chemical and pharmaceutical manufacturing. ...

High containment segment ball valve

Valves fitted in blenders and dryers can have dead spaces that prevent complete process...

Vacuum tray dryer for pharmaceutical applications

Optimize drying of heat-sensitive compounds while maintaining product i...

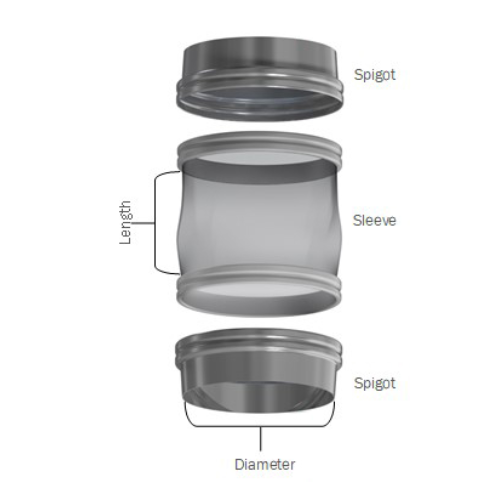

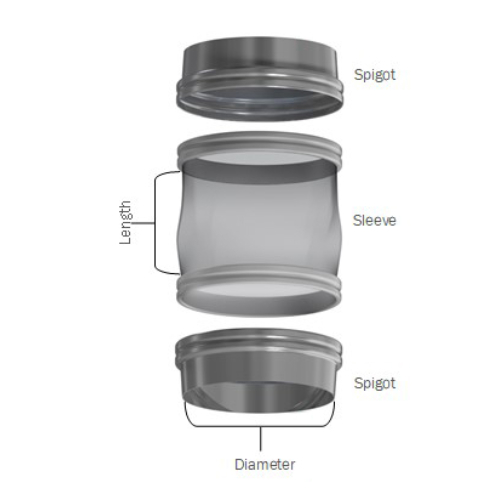

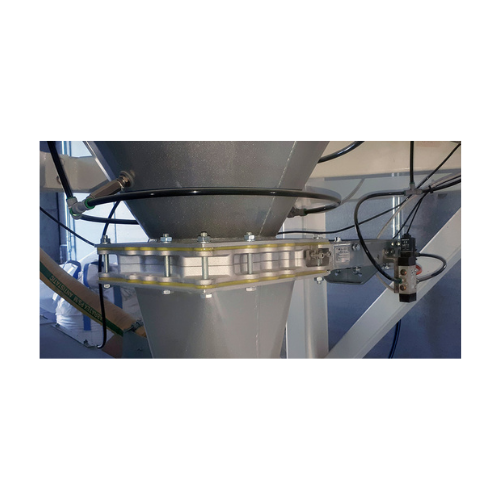

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

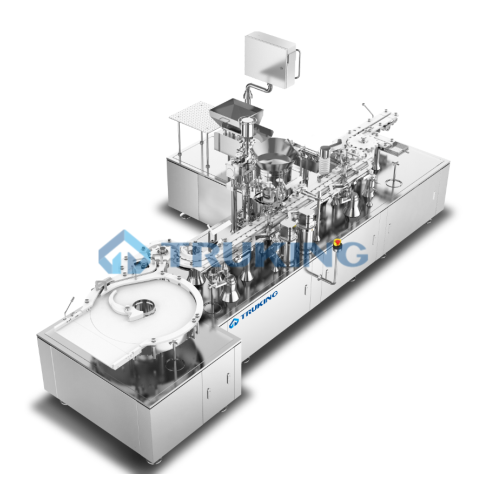

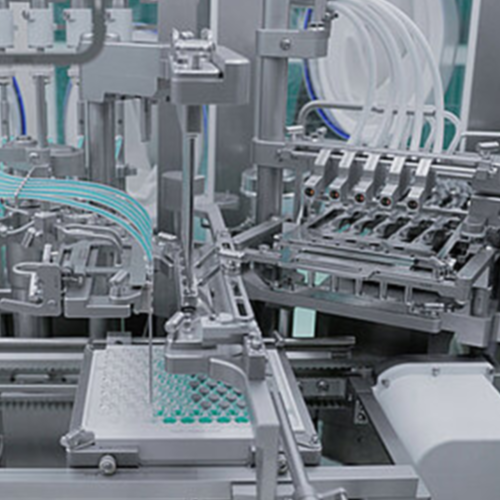

Aseptic filling and capping for vials and syringes

Ensure sterility and precision in vial and syringe filling with advanc...

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High speed powder dosing and stoppering for antibiotics

Address the threat of antibiotic-resistant bacteria with precisio...

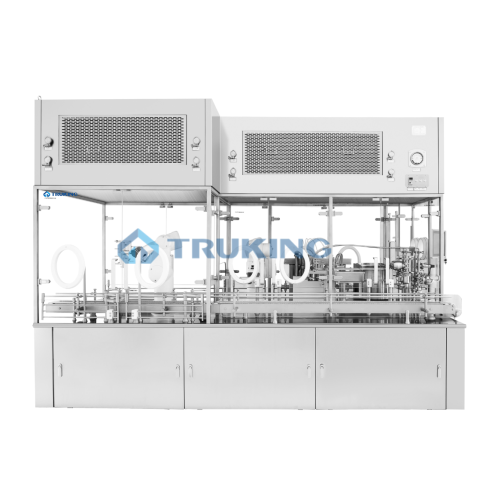

Isolation solutions for aseptic fill-finish lines

Achieve maximum product sterility with advanced isolation solutions, mi...

Fluid bed processor for pharmaceutical granulation and drying

Achieve precise drying, granulation, and coating of pharma...

Tablet press for high-quality pharmaceutical tablets

Ensure optimal tablet quality and yield with an advanced compression...

Batch drying system for pelleted products

Achieve precise moisture control and rapid drying for encrusted and pelleted see...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

Steam sterilizer for biomedical lab research

Ensure the highest level of biosafety and scientific integrity with this stea...

Cost-effective rigid-wall isolator for aseptic applications

Ensure sterility and safety with a versatile isolation and d...

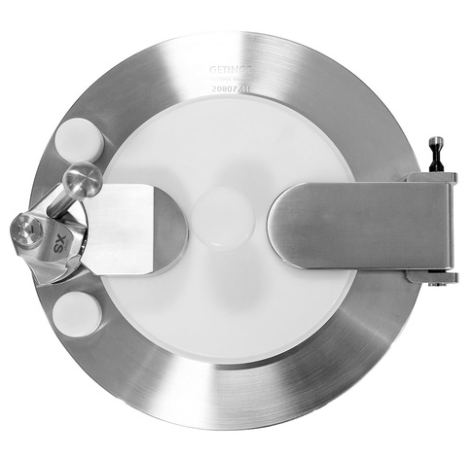

Aseptic transfer port for secure bi-directional transfer

Ensure seamless and contamination-free transfer of sterile mater...

Reusable containers for sterile and toxic material transfer

Ensure safe and contamination-free transfer of sterile and t...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Cleanroom air filtration unit for pharmaceutical production

Ensure sterile integrity in your manufacturing process with ...

Pharmaceutical isolator for contamination control

Ensure sterility and safety in pharmaceutical manufacturing with advanc...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

Shielded waste container for radioactive materials

Ensure safe containment and disposal of radioactive waste with a robus...

Laboratory work bench with integrated sink

Ensure precise containment and decontamination in radiopharmaceutical preparati...

Stainless steel vial container for personal protection

Ensure the safety and integrity of sensitive materials with robust...

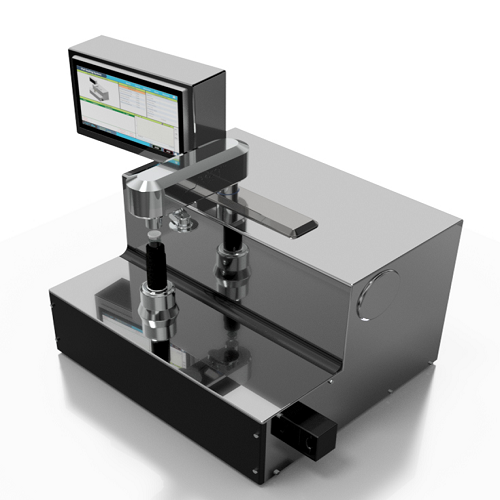

Automatic portable glove tester

Ensure glove integrity in critical environments with rapid, precise leak testing, safeguardi...

Shielded storage bench for radioactive waste

Ensure safe and efficient containment, storage, and transportation of radioac...

Syringe shielded container for radiopharmaceuticals

Ensure safe and efficient transport of sensitive radiopharmaceuticals...

Beta radiation shielding for vials

Ensure the safe handling and storage of radiopharmaceuticals with effective beta radiati...

Six stage r&d isolator for safe material handling

Ensure optimal operator safety and material containment during complex ...

Shielded radiochemistry fume hood

Enhance your lab’s safety and efficiency with a fume hood designed for precise hand...

Shielded isolator for radiopharmaceutical synthesis and dispensing

Ensure radiopharmaceutical purity and operator safet...

Modular dispensing and weighing isolator for pharmaceuticals

Achieve precise dispensing and weighing of high-potency pha...

Manual hot cell for r&d in radiopharmaceuticals

Ensure precise dose dispensing and safe handling of radioisotopes with thi...

Shielded cell for radiopharmaceutical synthesis

Ensure operator safety and seamless radiopharmaceutical synthesis with adv...

Isolator for cytotoxic drug handling

Ensure safety and compliance in handling cytotoxic drugs and radiopharmaceuticals with...

Isolators for safe Hapi transfer and dispensing

Ensure the safe, precise transfer and dispensing of highly active pharmace...

Isolator for washing procedures in pharma industry

Ensure complete isolation and safety during manual cleaning of pharmac...

Stainless steel wash basin for radiochemistry labs

Ensure precise decontamination and safe liquid handling in radiochemis...

Fume hood for handling medium activity radioisotopes

Ensure safety and precision in your laboratory processes with a fume...

Dispensing isolator for hazardous substance handling

Ensure maximum operator safety and contamination control when handli...

Double hot cell for radiopharmaceutical chemistry

Ensure optimal safety and compliance in handling radiopharmaceuticals w...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

Laminar flow hood with lead glass for laboratory use

Ensure sterility and precision in high-stakes environments with adva...

Radiochemistry fume hood

Ensure precise containment and filtration during radiochemical processes, safeguarding both operator...

Laminar flow hood for aseptic preparation

Ensure aseptic conditions for sterile injectable drug preparation with this adva...

Ventilated pass-through for classified environment transition

Ensure sterile and secure transfer between environments wi...

Bunker door for self-shielding cyclotron

Enhance the safety and efficiency of your cyclotron operations with a robust solut...

Shielded canisters for radioactive solid waste disposal

Ensure safe and efficient containment of radioactive solid waste ...

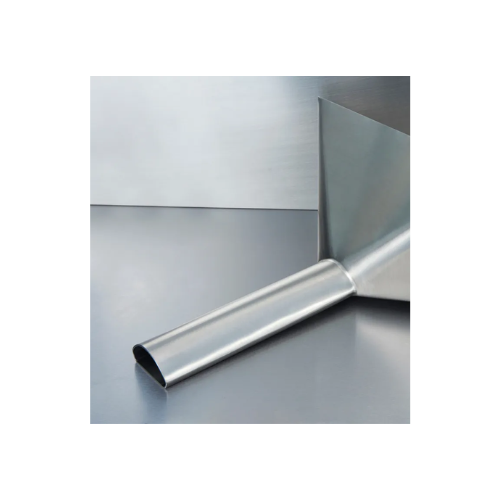

Powder dispensing funnel

Enhance powder handling accuracy while minimizing product loss with a precision-engineered dispensin...

Dust particulate extraction system

Ensure safe containment and minimize airborne particulates in your production line with ...

Lightweight plastic butterfly valve for industrial use

Achieve precise flow control and quick disassembly during pharmace...

Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder...

Single use valves for powder transfer

Efficiently transfer powder ingredients with a single-use containment solution, ensur...

Transfer valve cleaning for sterility assurance

Ensure seamless cleaning and sterility while maintaining containment integ...

Aseptic transfer valve for sterility assurance

Ensure sterility and safety in your critical production processes with adva...

Autoclave passive opener for sterilisation of passive valves

When sterilising passive valves, ensuring maximum exposure ...

Single use powder handling bags for pharmaceutical ingredients

Achieve contamination-free powder transfers with ease, ma...

Glove box furnace for high-temperature applications

Optimize your high-temperature heat treatment and containment process...

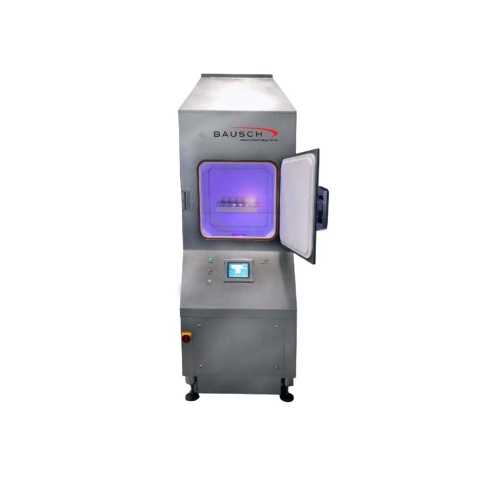

Hydrogen peroxide ultrafine particle sterilizer for contamination control

Ensure thorough sterilization in small space...

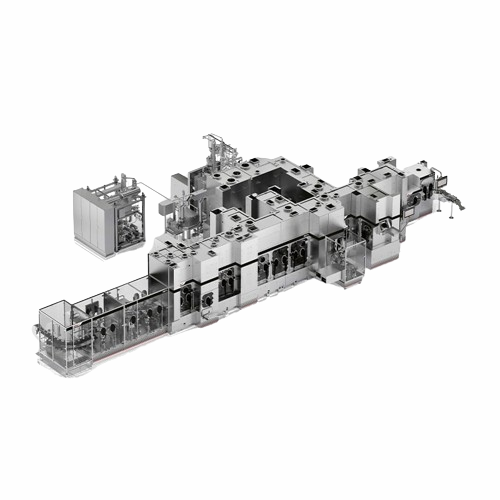

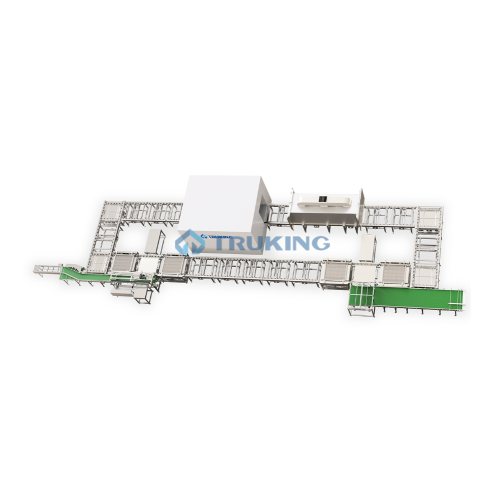

Non-sterile Api production line for powder and solid formulations

Ensure a dust-free, automated process for pharmaceuti...

Aseptic liquid transfer connection system

Ensure sterile liquid transfer between containment areas with minimal product lo...

Nsf certified class Ii a2 biosafety cabinet

Ensure laboratory safety and specimen integrity with a biosafety cabinet desig...

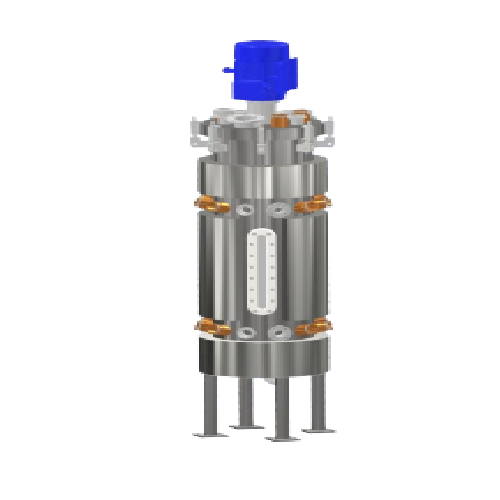

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

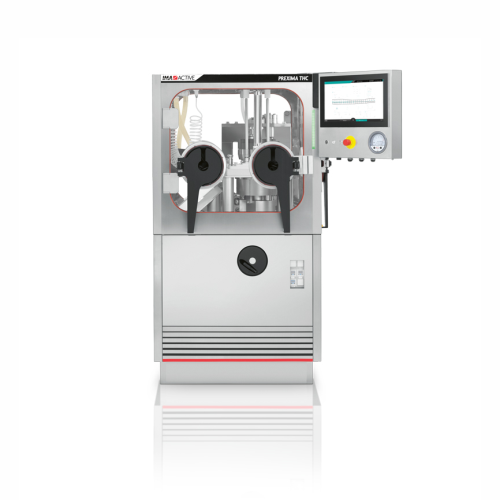

Next generation tablet compression unit

Meet the demands of modern tablet production with advanced modular design, ensuring...

Rotary tablet press for small to medium scale production

Optimize your tablet production with a versatile rotary press, o...

Medium-volume rotary tablet press for pharmaceuticals

Optimize tablet production with high-throughput and rapid changeove...

Silo unloading belt for food industry

Ensure seamless flow and precise control when unloading silos with this automated bel...

Contained powder sampling system

Ensure contamination-free sampling of active powders with fully contained system integratio...

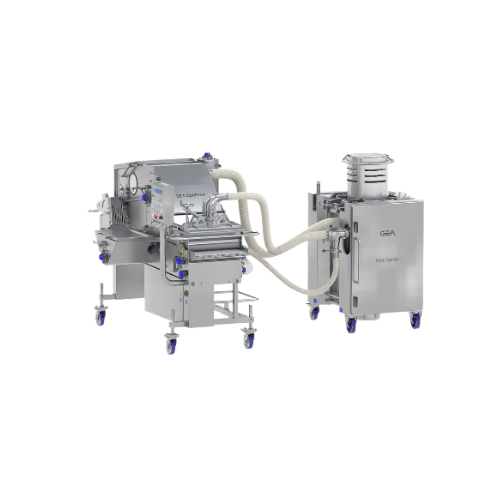

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet...

Automatic loading and unloading system for pharma freeze dryers

Enhance the efficiency and safety of your freeze-drying ...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Laboratory dedusting systems

Designed for high-containment lab environments, this solution efficiently captures and manages ...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

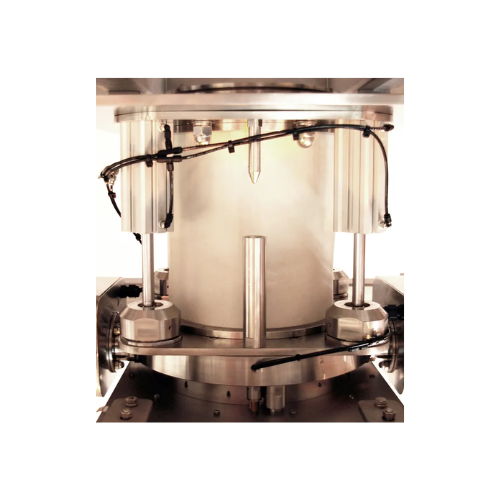

Vial powder dispensing system

Optimize your aseptic fill process with high-precision powder dispensing that minimizes contam...

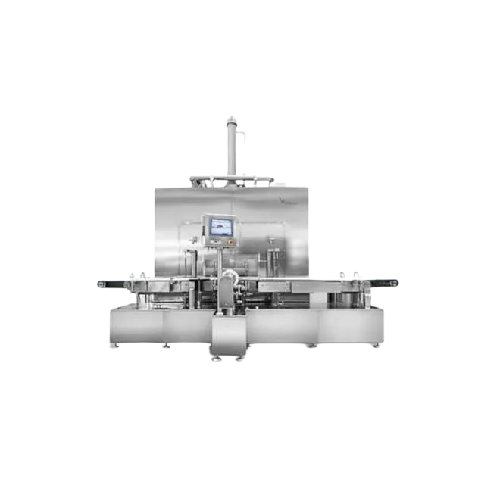

Nested fillers for vials, pre-filled syringes, and cartridges

Optimize your aseptic filling processes with precision dos...

Vial filling and stoppering system for aseptic production

Streamline aseptic production by integrating high-speed vial f...

Stainless steel container for bioprocessing

Optimize the containment and handling of large-volume biopharmaceutical liquid...

200l sterile tank liners for bioprocessing

Streamline your bioprocessing operations by eliminating tank cleaning steps and...

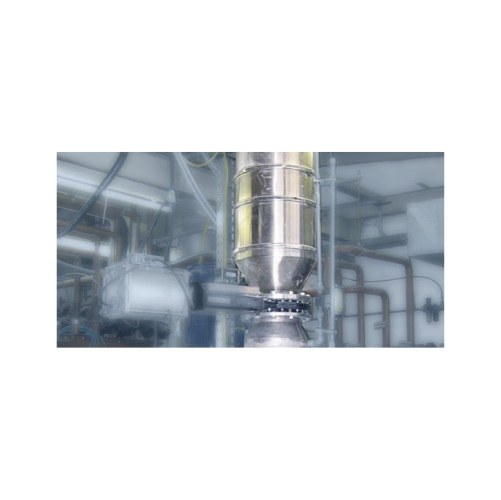

Downflow booths for hazardous material processing

Ensure product integrity and operator safety during hazardous material ...

Vertical laminar air flow cabinet for Pcr applications

Ensure your DNA-sensitive work remains uncontaminated with a compa...

Class Ii biological safety cabinet

Ensure optimal safety levels while handling biological agents with a compact, ergonomic ...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Class Ii biological safety cabinet for laboratory use

Ensure maximum protection for your laboratory personnel and samples...

Disposable isolator

Pharmaceutical powders need to be contained in the strictest conditions. But handling powders and cleanin...

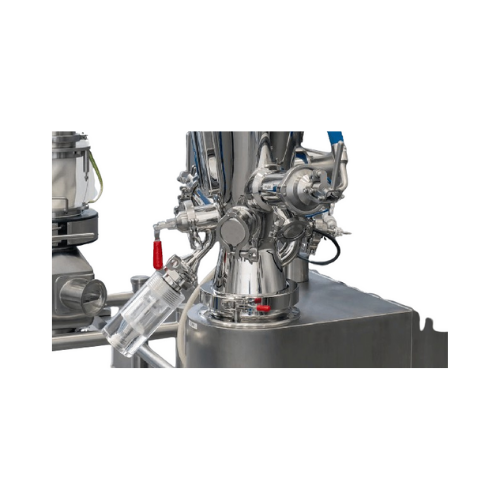

Filter dryer discharging isolator

Contained discharging is critical to the quality of filtration and drying processes. But ...

Contamination free filling system

Liners for powder handling across industries must prevent contamination of materials to c...

Big bag discharger

Big bags offer suitable material handling for powder products from pharma and food ingredients to bulk and...

Drum filling system

Pharmaceutical and chemical products may be toxic or prone to contamination from environmental exposure. ...

Drum emptying system

Handling products from the pharmaceutical and chemical industries requires careful attention and extreme...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Closed restricted access barrier system

Pharmaceutical production techniques often require isolation of compounds and chemi...

Contained capsule filler

For pharmaceutical formulations that are highly active specialized capsule filling equipment is ofte...

Half-suit tester

Designed to allow operators to perform sterility testing in an aseptic environment providing assurance of mat...

Glove tester

Testing device of the containment capability of gloves, which is as important as the other parts of the integrate...

Downflow booth

Provides the highest levels of operator protection from potentially harmful airborne contaminants generated dur...

Positive pressure isolator

Ideal for products which have no biological risk but require high sterile conditions.

Biological safety cabinet class III

Specially designed for the handling of microbiological agents, when working with indige...

Flexible contained powder charging solution

Filling of transportation bags and discharging them into mix tanks or reactor ...

Flexible contained charging for split butterfly valves

Poly bottles with split butterfly valves are often used to transfe...

Flexible contained handling of powder transfer bags

Filling of transportation bags and discharging them into mix tanks or...

Crimping system

Flexible disposable containment systems in the form of specially designed plastic bags are an excellent choice...

Flexible contained drum transfer system

Transferring powders from drums to process equipment such as reactors or mills can ...

Flexible contained powder discharge into drums

Powdered products are handled every day in the pharmaceutical and bioproces...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powder...

Visual inspection systems for packaging quality control

Detect and eliminate packaging and labeling faults early in your ...

Ion exchange for chloride and potassium removal in kraft mills

Optimize your kraft mill operations by efficiently removi...

Hygienic pipeline product recovery system

Efficiently recover valuable residuals from pipelines while streamlining your cl...

High-speed fill-finish system for ready-to-use components

Enhance aseptic fill-finish operations with a high-speed solut...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Vial and syringe filling system for pharmaceuticals

Ensure aseptic precision in liquid formulation filling with a modular...

Electrostatic filter for coffee roasting emissions

Mitigate unwanted odors and emissions in coffee roasting with high-eff...

Cgmp washer/dryer for biopharmaceutical cleaning

Achieve optimal cleanliness with precise washing and drying for biopharma...

Modular Gmp isolator for aseptic processing

Ensure contamination-free production with this modular aseptic isolator, desig...

Sterile transfer bags for aseptic production

Ensure contamination-free and efficient component transfer in high-speed asep...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Iso 5 Hepa cart for aseptic material transfer

Ensure aseptic conditions during storage and transfer with this compact HEPA...

Sterility testing isolator for aseptic environments

Ensure aseptic conditions and process integrity during sterility test...

Cleanroom infrastructure for contaminant control

Ensure optimal contaminant control and regulatory compliance in cleanroom...

Modular cleanroom panel systems

Transform your cleanroom projects with modular panel systems that streamline installation an...

Single-use bioreactors for mammalian and insect cell cultivation

Optimize your bioprocesses with scalable, single-use bi...

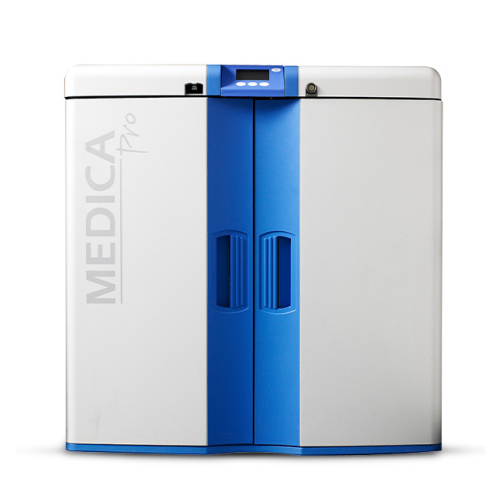

High-purity water system for clinical diagnostic analyzers

Ensure your clinical analyzers receive uninterrupted, high-pu...

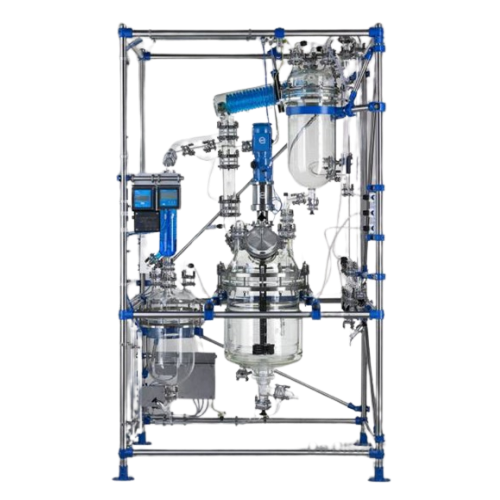

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, t...

Supercritical Co2 extraction system

Optimize your extraction processes with environmentally friendly and efficient supercri...

Isolator for Vphp decontamination testing

Ensure precise decontamination analysis and stringent monitoring of hydrogen per...

Shielded Wc for disposal of organic radioactive waste

Effectively manage and neutralize radioactive and organic waste wit...

Shielded door for cyclotron bunker

Ensure optimal radiation protection and seamless operation within cyclotron bunkers with...

Radiopharmaceutical dispensing isolator for vials and syringes

For precise radiopharmaceutical preparation, this isolato...

Custom automation for drug-device filling and assembly

Efficiently integrate precise filling and assembly for biopharmace...

Sterile isolator for cellular labeling

Ensure sterility and protection in cellular labeling processes with an isolator that...

Mini plant isolator for laboratory protection

Ensure maximum operator safety and product integrity with a versatile isolat...

Laminar flow shielded cell for radiopharmaceutical research

Ensure aseptic conditions and precise dose calibration for i...

Isolator for aseptic cell culture processing

Ensure sterility and reduce cross-contamination risks in your cell culture pr...

Radioactive waste disposal system for medical facilities

Handle radioactive waste safely by utilizing an automated system...

High quality sterile filling system

Experience unparalleled precision in aseptic filling with this advanced system, designe...

Decontamination shower system for industrial use

Ensure optimal purification and safety with a specialized shower system d...

Custom r&d isolator for precise dispensing operations

When handling sensitive compounds, precision and operator safety ar...

Automatic aseptic filling line for Iv bags

Ensure aseptic integrity and high-speed processing of IV bags with a filling li...

Air compressing station for radiopharmaceutical labs

Efficiently manage and monitor potentially contaminated air in radio...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

Stainless steel container for powder transfer

Ensure seamless and sterile movement of high-value powders with this contain...

Ashing furnace for sensitive analytical applications

Ensure analytical purity and safely test materials by containing cor...

Synthesis gas cooler for partial oxidation of oil or natural gas

Optimize high-temperature gas streams efficiently by em...

Vapour recovery unit for terminals and refineries

Efficiently capture and recover valuable hydrocarbons from gas streams,...

Carbon capture membranes for Co2 separation

Efficiently reduce carbon emissions in power plants and industrial operations ...

Pressure equipment directive (ped) compliant tanks

Achieve precise pressure regulation and safety with tanks designed to ...

Sterile media and buffer storage tanks

Ensure uninterrupted bioproduction with our tanks designed for secure storage and pr...

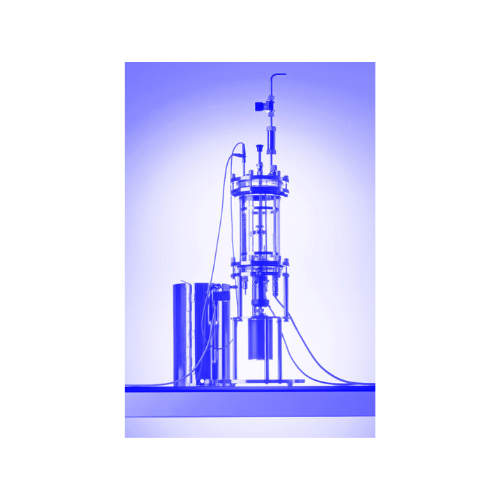

Lab-scale in-situ sterilizable bioreactor

Ensure precision in your laboratory and pilot projects with this bioreactor, des...

Sterile transfer chamber for pharmaceutical components

Ensure the sterility of your components rapidly with an enclosed c...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Cleanroom enclosure system for pharmaceutical and chemical industries

Ensure sterile environments with this customizabl...

Bench-top vial sealing system for pharmaceutical use

Ensure precise sealing of pharmaceutical vials with a system designe...

Centrifugal evaporator for medicinal chemistry

Achieve precise evaporation and crystallization with innovative anti-bumpin...

Automated quality control for food packaging

Ensure seamless quality control with real-time inspections, serialization, an...

Belt press for industrial sludge dewatering

Achieve efficient sludge dewatering with minimal energy and polymer use, maxim...

Mixproof valve for cleaning-in-place control

Streamline your cleaning processes and ensure product safety with a versatile...

Vhp biodecontamination passbox for laboratory equipment

Ensure effective decontamination for heat-sensitive and non-autoc...

Batch decontamination system for effluents with particles and variable viscosity

Effectively manage complex effluent s...

50l stainless steel dual-jacketed reactor for chemical processes

Optimize your laboratory’s efficiency with a dual...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Product recovery system for hygienic applications

Efficiently reclaim valuable products from your production lines while ...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Intermediate bulk container (ibc) blending for pharmaceutical manufacturing

Streamline your pharmaceutical blending pr...

Dust-free flour applicator for food coating

Eliminate dust from your coating process with precise flour application, ensur...

Wash-off-line system for pharmaceutical plants

Optimize your production with a versatile wash-off-line system, ensuring pr...

Industrial rotary sifter for bulk materials

Ensure precision and quality in your production line with a robust solution de...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Industrial bin vent filter for fine dust particles

Enhance your production line with efficient fine dust filtration to en...

Industrial control cabinets and control stations

Streamline your plant operations with customizable control cabinets and s...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Dust-free bulk bag filling system

Achieve efficient, dust-free filling of bulk bags with our innovative system, ensuring se...

Dust collector for dry-batch concrete plants

Ensure dust-free loading of truck mixers in dry-batch concrete plants with an...

Vacuum conveyors for explosive and inert gas environments

Optimize the safe transfer of hybrid mixtures and fine powders...

Pharmaceutical vacuum conveyors for hygienic transport

Ensure contamination-free transport of sensitive pharmaceuticals a...

Vacuum dispersion system for laboratory applications

Achieve precise mixing and homogenization under vacuum conditions, e...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

Robotic sterilization logistics system

Ensure seamless aseptic transfers across production stages with this robotic logisti...

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Autoclave unloading isolator for sterile assembly

Ensure aseptic conditions and prevent microbial contamination during th...

Sterility testing isolator for aseptic environment

Ensure precise sterility testing and prevent contamination with an iso...

Isolator for sterility testing in pharmaceutical manufacturing

Ensure precise sterility testing with advanced isolators ...

Cell expansion system for antibody drug production

Enhance your biopharmaceutical production with efficient cell expansio...

Pilot-scale bioreactors for bioprocess scale-up

Bridge the gap between experimentation and large-scale production with pil...

High-pressure hydrogen generator for laboratory use

Replace cumbersome hydrogen cylinders with an on-demand generation so...

Industrial bag filter for powder collection efficiency

For producers seeking to enhance powder yield while minimizing emi...

Freeze dryer & filling line aseptic isolator for cytotoxic products

Handle cytotoxic and high-potent drugs with precisi...

Sterile lyophilisation and filling line

Ensure aseptic conditions while freeze-drying biopharmaceuticals and high-potent dr...

Aseptic barrier isolators for pharmaceutical applications

Enhance sterility and operator safety during aseptic processin...

Restricted access barriers systems for aseptic processing

Enhance product safety by separating operators from the critic...

Bio-decontamination pass-through hatch for aseptic facilities

Ensure sterile transfer of materials between classified ar...

Biological safety cabinet for medication preparation

Enhance medication preparation safety and reduce error rates with a ...

Class Ii biological safety cabinets for vaccine production

Ensure stringent safety and environmental standards with cust...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Industrial cyclone separators for air particulate removal

Optimize particulate removal in air streams with cyclone separ...

Refrigerated vacuum cold trap for chemical vapor applications

Efficiently trap corrosive vapors and eliminate the need f...

Full flow filtration system for bioprocess applications

Ensure sterile filtration of process liquids and aseptic chemical...

Soft pack isolator for rats and mice

Ensure a sterile and controlled environment for laboratory mice and rats with this sof...

Fume hood with pipes for chemical laboratories

Ensure maximum safety and efficiency in your laboratory by effectively exha...

Storage cabinet for endoscopes

Ensure the safe, contamination-free storage and easy monitoring of endoscopes with a hanging ...

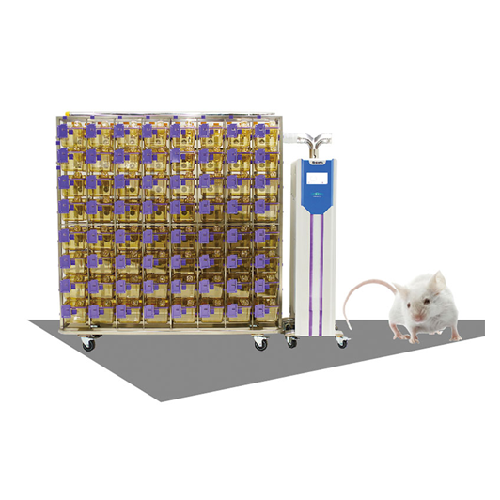

Individually ventilated cage system for Spf rodents

Ensure optimal conditions for your laboratory animals with a cage sys...

Aseptic test isolator for sterility inspection

Ensure stringent sterility control in your laboratory or production line wi...

Powder dosing system

Dosing of powder products must be done in a continuously controlled manner to provide a precise amount o...

Powder transfer system

Loading powder from a container source to vessels, tanks, or mixers that are under pressure may be haz...

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Single-use powder handling bag

Containers for handling pharmaceutical and biopharmaceutical powders may be disposable, to av...

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Start-up sterile filling line for injectables

For smaller-scale production of vials and syringes for the injectables marke...

Start-up sterile filling line for ophthalmics

Commencing ophthalmic production requires sterile conditions and accurate me...

Table top sterile filling line for injectables

Where a compact solution is required for filling vials for the injectables ...

Compounding aseptic isolator

Bespoke aseptic isolators designed for production environments don’t meet the needs of small-sc...

Sterile compounding system

Hospitals and compounding centres have traditionally used manual aseptic compounding processes. A...

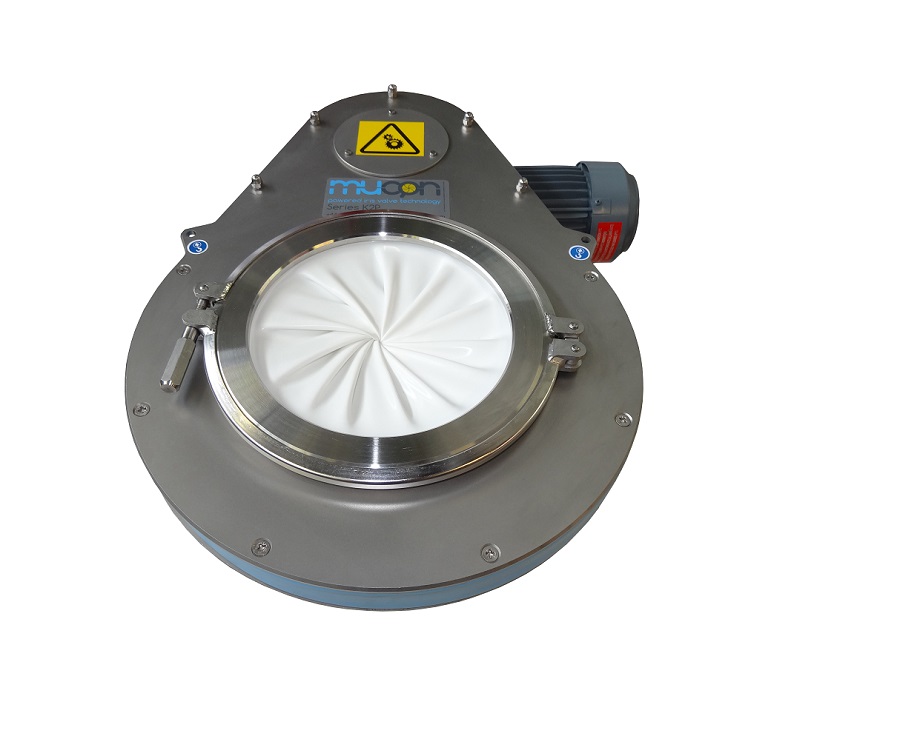

Hygienic automatic iris valve

In automated systems where controlled discharge of powders and bulk solids is required with a ...

Hygienic hand-operated iris valve

Hand-operated valves are required for the walls of clean rooms for glanding around cables...

Slide gate valve

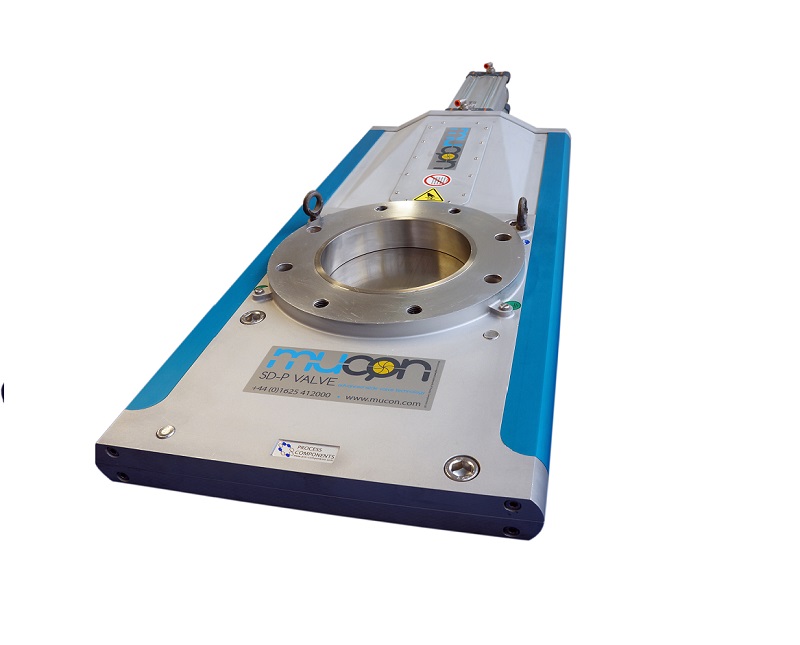

In the powder and bulk handling industries, in-line shut off valves are required to provide uninterrupted smo...

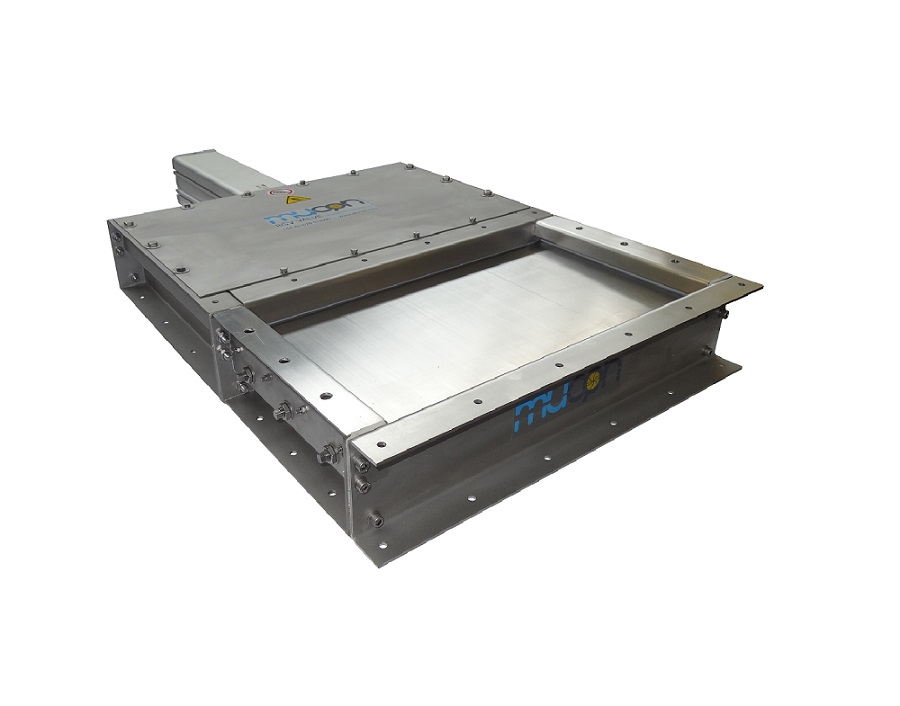

Roller gate valve

In large scale operations, modular and configurable valves are required to isolate and control dry powders,...

Bellows for pharmaceutical powders

Thermal and mechanical changes can lead to stresses in industrial piping systems. These ...

Sterile filling line for injectables

Sterile filling of liquids and powders for the pharmaceutical and cosmetic industries ...

Sterile filling line for ophthalmics

Demanding very high standards, the ophthalmic market requires quality solutions for fi...

Negative pressure isolator

Used for products biologically hazardous, that also require minimized cross contamination.

Vertical laminar flow cabinet

HEPA filtered vertical laminar airflow (down flow) creates an ISO 14644-1 (Class 5) work area ...

Horizontal laminar flow benches

HEPA filtered horizontal laminar airflow (crossflow) creates an ISO 14644-1 (Class 5) work a...

Compact horizontal laminar flow bench

HEPA filtered horizontal laminar airflow (cross-flow) creates an optimized free space...

Microbiological safety cabinet class II

This handy device offers the most advanced features in product-operator protection ...

Biosafety cabinet class II for cytotoxic medicines

For the manipulation of hazardous substances utilized during the prepa...

Aseptic barrier systems

Designed for sterile product and Potent API’s either with low or high OEL requirements.

Restricted-access barrier systems

Create a physical barrier between the operator and the product. More flexible than an iso...

Sterility test isolators

Designed to avoid this risk and protect the product from both the process and externally generated f...