Isolator for aseptic cell culture processing

Ensure sterility and reduce cross-contamination risks in your cell culture processes with cutting-edge isolation technology, providing a controlled Class A environment for regenerative medicine and advanced therapies.

Ensures Aseptic Processing and Controlled Cell Culturing

The Modular Cell Culture Isolator (MCC) offers an advanced solution for regenerative medicine and tissue engineering processes, designed by Comecer for environments requiring strict aseptic conditions. What sets this isolator apart is its seamless integration of modular components and cutting-edge isolation technologies, ensuring operator safety and product sterility. The MCC facilitates complex biopharmaceutical applications such as stem cell and gene therapy production. Operating within a Class A environment, it utilizes HEPA H14 filtration and positive pressure systems to maintain a contaminant-free atmosphere. Its modular design allows for flexible configuration, catering to the specific needs of biotech centers and tissue engineering labs. Equipped with automated viable and non-viable monitoring, alongside a user-friendly SCADA system for process control, the MCC ensures compliance with GMP standards and FDA regulations. Energy-efficient decontamination is achieved through H2O2 cycles, significantly reducing operational costs in comparison to traditional cleanroom setups. The MCC supports customization, offering multiple material options for compatibility with various production requirements.

Benefits

- Ensures high sterility assurance levels, minimizing contamination risk during cell therapy production.

- Reduces operational costs with integrated H2O2 decontamination, compared to full cleanroom sterilization.

- Enhances process efficiency with modular design, allowing for rapid configuration changes.

- Maintains compliance with stringent GMP and FDA guidelines for advanced therapeutic products.

- Streamlines operations through automated environmental monitoring and control, minimizing human error.

- Applications

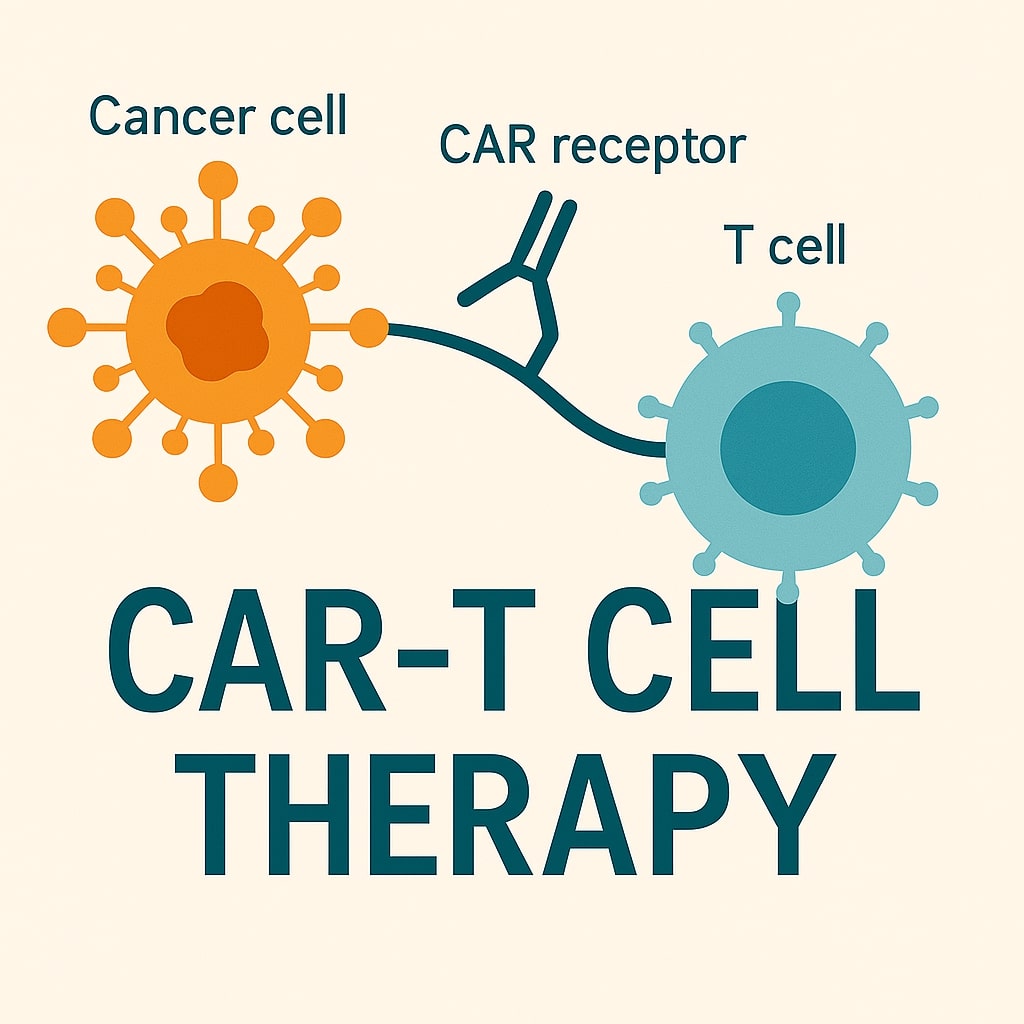

- Pharmaceutical aseptic processes, Regenerative medicine, Biotech, Tissue engineering, Advanced therapy medicinal products (atmp), Cell therapies

- End products

- Car-t cell therapies, Gene therapy products, Tissue-engineered skin, Personalized cell therapies, Monoclonal antibodies, Cell-based vaccines, Biopharmaceuticals, Stem cell therapies, Human skin equivalents

- Steps before

- Tissue Preparation, Cell Isolation, Culture Media Preparation

- Steps after

- Sterility Assurance, Quality Control, Packaging

- Input ingredients

- tissue samples, cell cultures, H2O2 cartridge, biological materials

- Output ingredients

- regenerated tissue, cell therapy products, advanced therapy medicinal products, sterile environment

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Ventilation Strategy

- Laminar Airflow with HEPA H14 filter

- Exhaust Filters

- H14

- Decontamination System

- H2O2 Gas

- Pressure

- Positive Pressure

- Control Software

- GAMP 5 Software

- SCADA System

- 21 CFR Part 11 compliant

- Monitoring

- Viable and Non-Viable Continuous Monitoring

- Modular Design

- Yes

- Environment

- Class D for installation

- Class A workspace

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- VPHP cycle / Automated

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Smaller footprint of the classified areas

- Glove Box Installation

- Available for smaller facilities

- Footprint

- Compact design for efficient space utilization