Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a snap-in connector system that simplifies installation and maintenance, ensuring a dust-tight seal without the need for tools.

Snap-Connects and Seals Flexibly

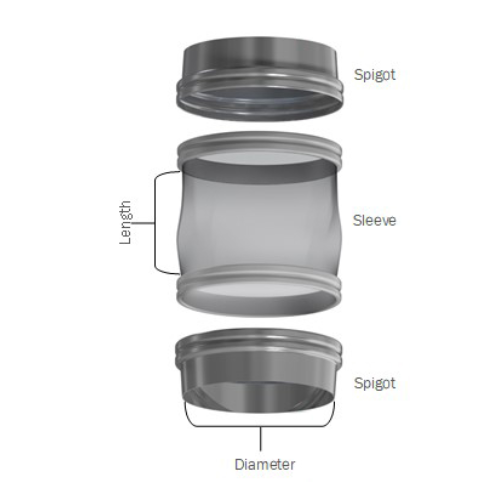

The BFM® Flexible Connector System from Powder-Solutions, Inc. revolutionizes the way you handle and connect bulk powder processes. Designed to snap-connect and seal without tools, it offers a cleaner, leak-free environment ideal for industries such as dairy, food, infant nutrition, and pharmaceuticals. The snap-in sleeves, combined with precision-engineered spigots, allow for simple integration into existing production lines, ensuring seamless transitions between processing stages. This system significantly minimizes product build-up, enhancing hygiene and reducing downtime during cleanings and changeovers.

BFM® fittings provide a 100% sealed connection, utilizing patented snap bands for a secure fit that tightens under pressure. With options in both breathable and non-breathable materials, it accommodates a variety of processing requirements and material consistencies, from powdered milk and cheese to pharmaceutical capsules and plastic resins. While throughput capacity varies depending on your specific system setup, BFM® fittings support continuous and high-speed operations, ideal for dynamic manufacturing environments.

Integration with existing systems is straightforward, as standardized sizes reduce the need for extensive inventory. The absence of tools in installation simplifies maintenance, while the durable materials ensure longevity and resilience against wear and corrosion, particularly in intense processing conditions. Additionally, the fittings align with industry best practices for cleaning and safety, supporting hygienic manufacturing objectives and regulatory compliance. Whether you need to customize dimensions or material types, engineering support is on hand to tailor the solution to your specific processing line requirements.

Benefits

- Facilitates quicker changeovers by eliminating tool requirements, enhancing production efficiency.

- Minimizes contamination risk with a 100% sealed, leak-free connection.

- Reduces downtime and maintenance costs through easy, hands-free installation and removal.

- Optimizes inventory with standardized connector sizes, reducing storage needs.

- Enhances worker safety by securely containing powders and preventing exposure.

- Applications

- Food, Sugar, Infant nutrition, Specialty industries, Bakery, Concrete, Plastic, Medical technology, Nutritional powders, Plaster, Dairy, Pharmaceutical

- End products

- Vitamins, Plaster powder, Concrete mix, Plastic resin, Premix powder, Granola bars, Pharmaceutical capsules, Polymer granules, Gypsum board, Icing sugar, Milk powder, Refined sugar, Yogurt powder, Pvc pellets, Nutritional shakes, Cheese powder, Bakery premix, Baby formula, Nutraceuticals, Protein supplements, Tablets

- Steps before

- Mixing, Blending, Grinding, Milling, Weigh Batching

- Steps after

- Packing, Filling, Dust Collection, Vacuum Cleaning, Filter Receiving

- Input ingredients

- bulk powder, food, dairy, nutritional powders, pharmaceutical powders, specialty products

- Output ingredients

- dust-tight powder, contained product

- Market info

- PPS (Powder Process-Solutions) is known for designing and manufacturing custom powder handling systems and equipment, specializing in sanitary process solutions for the food, dairy, and nutritional industries, ensuring safety, efficiency, and regulatory compliance.

- Sealing

- 100% sealed, no leaks

- Pressure Response

- Seals tighter under pressure

- Installation

- Tool-free snap-in design

- Connector Sizes

- Standardised sizes

- Cleaning Method

- Easy tool-free cleaning

- Material Type

- Non-breathable/Breathable

- Sleeve Material

- Seeflex 040E, Seeflex 020E, Seeflex 060E etc.

- Dust Containment

- Dust-tight flexible connector

- Connection Type

- Snap-in connector and spigot

- Product Viewing

- Transparent for product viewing

- Working mechanism

- Snap-in flexible connector

- Integrated steps

- Tool-free cleaning and changeover

- Pressure handling

- Seals tighter under pressure

- Installation method

- Manual snap-in design

- Batch vs continuous operation

- Suitable for batch operations

- Cleaning method

- Manual

- Changeover time

- Quick snap-in installation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product containment

- Dust-free environment

- Compact footprint

- Yes

- Discharge method

- Snap-in design

- Connector type

- Snap-in, flexible connector

- Material options

- Non-breathable/Breathable connectors

- Spigot type

- Matched BFM® spigots

- Dust containment

- 100% sealed, no leaks

- Tool-free installation

- Snap-in design

- Standardized sizes

- Less stock needed

- Viewing capability

- Available in connectors