Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient containment and isolation in pharmaceutical and biopharmaceutical processing.

Ensures Containment and Isolation for Safe Processing

The Flexible Isolator by AUSTAR is engineered to provide premium containment and isolation solutions for pharmaceutical, biopharmaceutical, and chemical processing environments. This versatile equipment is distinguished by its ability to accommodate various processes such as dispensing, filtration, charging, and milling. It is particularly suited for handling sterile injectable drugs, monoclonal antibodies, APIs, and pharmaceutical tablets. Designed with flexible materials, it allows for significant operating space and enhanced visibility, meeting stringent GMP and FDA standards. The isolator supports seamless integration with existing production lines, offering automation capabilities that ensure efficiency and safety. AUSTAR provides options for customization and engineering support, enabling tailored solutions to meet specific operational requirements. Maintenance is simplified through the inclusion of features like easy-to-clean surfaces, ensuring minimal downtime and contamination risk.

Benefits

- Maximizes safety by ensuring complete containment during hazardous material processing.

- Enhances productivity with integration-ready design for seamless operation across production lines.

- Boosts visibility and operational flexibility with transparent, flexible materials.

- Minimizes contamination risk with easy-to-clean surfaces and compliant design.

- Offers economic efficiency with its low initial investment and high adaptability.

- Applications

- Chemicals, Pharmaceutical tablets, Nutraceuticals, Biopharmaceuticals, Pharmaceutical powders, Pharmaceuticals

- End products

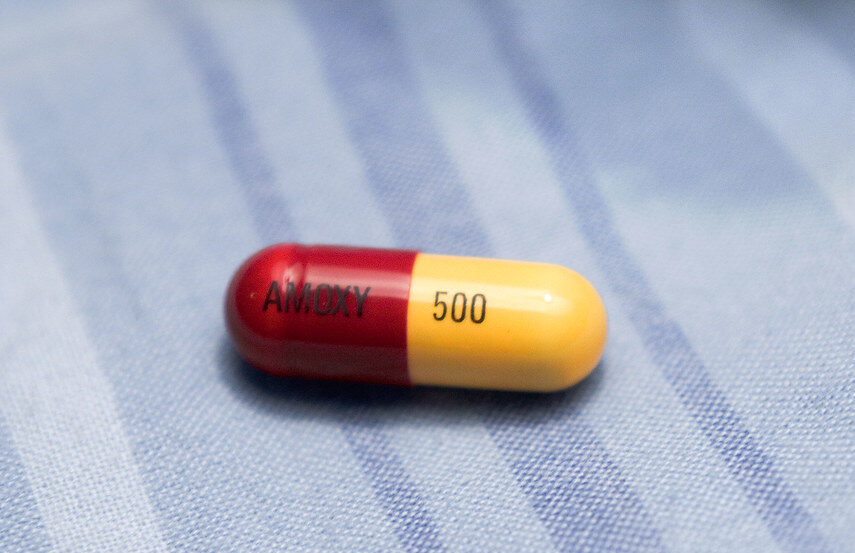

- Sterile injectable drugs, Active pharmaceutical ingredients (apis), Monoclonal antibodies, Vitamin supplements, Amoxicillin capsules, Paracetamol tablets

- Steps before

- Dispensing, Glass reactor charging, Filtration, Powder conveying

- Steps after

- Drainage, Centrifuge scoop-out, Dryer/freeze dryer discharging, Sampling, Granulating, Tableting, Coating

- Input ingredients

- Dispending materials, Glass reactor ingredients, Filtration inputs, Powder for sampling, Nutsche filter/dryer inputs, Reactor feed materials, Milling ingredients, Granulating components, Tableting materials, Coating chemicals, Centrifuge materials, Dryer/freeze dryer feed

- Output ingredients

- Filtered waste, Isolated substances, Sampled powders, Nutsche filter/dryer outputs, Discharged materials, Milled products, Granulated products, Tableted goods, Coated substances, Isolated centrifuge contents, Dried/freeze-dried outputs

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Material

- Flexible materials

- Investment Cost

- One-time low investment

- Transparency

- Higher transparency

- Cleaning Level

- Thoroughly cleaning

- Operating Space

- More operating space

- Containment level

- Isolation

- Application flexibility

- Multiple operations (dispensing, charging, filtration, etc.)

- Material flexibility

- Flexible materials used

- Cleaning method

- More thoroughly cleanable

- Transparency

- Higher transparency

- Investment level

- One-time low investment

- Integration capability

- Can be docked with more devices

- Economic efficiency

- Higher economic efficiency

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material Type

- Flexible materials

- Transparency

- Higher transparency

- Operating Space

- More operating space

- Footprint

- Compact

- Integration

- Can be docked with more devices

- Integration Possibilities

- Can be docked with more devices

- Material Flexibility

- Flexible materials to meet more operating space

- Operating Space

- Larger operating space due to flexibility