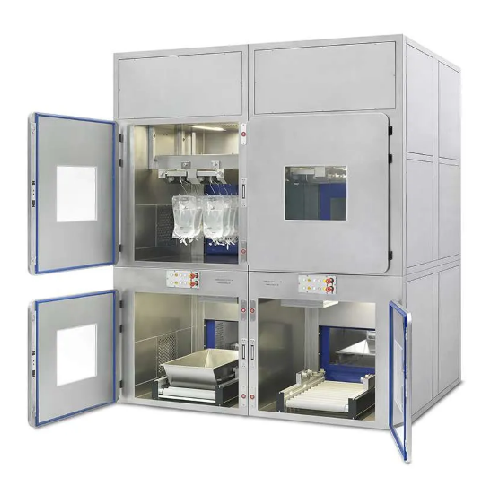

Bio-decontamination pass-through hatch for aseptic facilities

Ensure sterile transfer of materials between classified areas, minimizing contamination risks with an integrated bio-decontamination system.

Facilitates Secure Bio-Decontamination and Sterile Transfer

Telstar’s SAS Pass Through Boxes are engineered to enhance the bio-decontamination and sterile transfer process within pharmaceutical and biotech production facilities. These systems specialize in securely moving materials between different classified areas, pivotal for manufacturing sterile injectable drugs and regulated biologics. The SAS Pass Through Boxes, including the Biological SAS ION HP+ and HEPA Filtered SAS variants, utilize advanced filtration and bio-decontamination technology. The Biological SAS ION HP+ integrates an ionHP+ hydrogen peroxide decontamination system, co-developed with sterilant experts, ensuring a minimum 6-log reduction in microbial spores without preconditioning of standard temperature and humidity. Configurations accommodate various production line layouts with options for multiple doors and configurations in L-shape. Compliance with GMP standards ensures integration into highly regulated environments. Customizable features such as transfer trolleys and catalytic devices, alongside robust SCADA control systems, enable seamless operations and reporting. These units are rigorously designed to support stringent pharmaceutical processes, making material handling efficient, safe, and compliant with industry regulations.

Benefits

- Ensures sterile transfer of materials, minimizing contamination risks in aseptic environments.

- Eliminates up to 99.9999% of microbial spores with ionHP+ hydrogen peroxide decontamination.

- Customized configurations adapt to specific production line needs, enhancing operational flexibility.

- Reduces labor and reporting efforts with automated SCADA system controls and data management.

- Complies with stringent GMP standards, maintaining regulatory adherence in pharmaceutical manufacturing.

- Applications

- Biopharmaceuticals, Regulated products, Pharmaceuticals

- End products

- Sterile injectable drugs, Biotechnological product batches, Regulated medicinal packaging, Lyophilized pharmaceuticals, Pre-filled syringe solutions, Monoclonal antibody injections, Aseptic packaging of biologics, Api (active pharmaceutical ingredients) containers, Vaccine vials

- Steps before

- Material preparation, Initial decontamination, Sorting and staging of materials

- Steps after

- Bio-decontamination, Quality assurance, Transfer to aseptic production facility

- Input ingredients

- materials, documents, bio-contaminated materials, aseptic products

- Output ingredients

- sanitized materials, bio-decontaminated materials, transferred products, sterilized materials

- Market info

- Telstar is known for specializing in the design, engineering, and manufacturing of advanced vacuum and aerospace solutions, gaining a strong reputation for their innovative and customized equipment in pharmaceutical, medical, and scientific research sectors.

- Air-tight transfer chamber

- Yes

- Filtration System

- HEPA filtered air, on-board fans

- Bio-decontamination system

- Ionised Hydrogen Peroxide (IonHP+)

- Cycle control

- SCADA control system

- UV Lighting

- Yes

- Bio-decontamination cycle

- Ionised Hydrogen Peroxide

- Interlocked doors

- Yes

- Air-tight transfer chamber

- Inflatable gasket

- Automation level

- SCADA controlled

- Decontamination method

- H₂O₂ and UV light

- Cycle time

- Customizable

- Configuration

- 3 doors / doors in L

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable

- Footprint Size

- Standard or customizable to suit footprint

- Door Configuration

- 2-door, 3-door, or L-shaped

- Chamber Type

- Air-tight transfer chamber

- Inflatable Gasket

- Yes

- Door Configuration

- 3 doors, L-shaped doors

- Transfer Chamber Design

- Air-tight with inflatable gasket

- Bio-Decontamination System

- Integrated ionHP+ or external hydrogen peroxide generator

- Filtration System

- HEPA Filters

- UV Lighting

- Yes

- Control System

- SCADA

- Additional Accessories

- Transfer trolleys, catalytic decomposition device, H2O2 room sensors