Air compressing station for radiopharmaceutical labs

Efficiently manage and monitor potentially contaminated air in radiopharmaceutical environments with precision air compression and storage, ensuring safe discharge post-decontamination.

Compresses and Stores Radioactive Air Safely

The ACS 800 Air Compressing Station from Comecer is engineered for precision handling of potentially radioactive air in radiopharmaceutical and nuclear medicine applications. This system stands out by incorporating a membrane compressor designed to create negative pressure within the intake mode, efficiently compressing and storing air. Connected to up to 16 cells and capable of managing up to 5 production boxes simultaneously, it streamlines contaminated air handling and storage. Equipped with pressure gauges and a Geiger probe within a Marinelli system for contamination monitoring, the ACS 800 ensures the reliability of your safety operations. It integrates seamlessly with COMECER production cells and can interface with cyclotron vacuum pumps, providing a critical safety measure during target malfunctions. With a 200-litre air accumulation and storage tank system, it offers robust air management, while the 50-litre vacuum tank extends its storage capabilities. Illuminate™ manufacturing intelligence supports real-time performance monitoring and is crucial for sustainable production improvements. The ACS 800 adheres to strict safety and environmental standards, fulfilling compliance needs and ensuring that your facility remains operational and secure.

Benefits

- Ensures safety by securely managing and storing potentially radioactive air.

- Minimizes operational risks with continuous, automated air handling processes.

- Integrates seamlessly with existing radiopharmaceutical production setups.

- Enhances monitoring with real-time contamination detection and system feedback.

- Supports compliance with stringent radiopharmaceutical and environmental safety standards.

- Applications

- Cell, Radiopharmaceuticals, Gene therapy, Atmp applications, Radiopharma accessories, Pharmaceutical isolators, Nuclear medicine

- End products

- 0, Iodine-131 capsules, Technetium-99m generators, Yttrium-90 microspheres

- Steps before

- Synthesis, Hot cell containment, Cyclotron operation

- Steps after

- Radioactive decay monitoring, Discharge of decontaminated air, General ventilation extraction

- Input ingredients

- potentially radioactive air, air from hot cells, contaminated air

- Output ingredients

- compressed air, stored air in pressurised tanks, discharged, no longer contaminated air

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Connected Cells

- Up to 16 cells

- Production Capacity

- Up to 5 boxes simultaneously

- Valve System

- Three-valve system (2 pneumatic, 1 electric)

- Pressure Measurement

- Positive and negative pressure gauges

- Air Accumulation Tank

- 200 litres

- Storage Tank

- 200 litres

- Vacuum Tank

- 50 litres

- Compressor Type

- Membrane compressor

- Intake Mode

- Negative pressure creation

- Monitoring System

- Geiger probe in Marinelli system (optional)

- Software Platform

- Illuminate™ MI

- Storage Function

- Compressed and stored in pressurised tanks

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

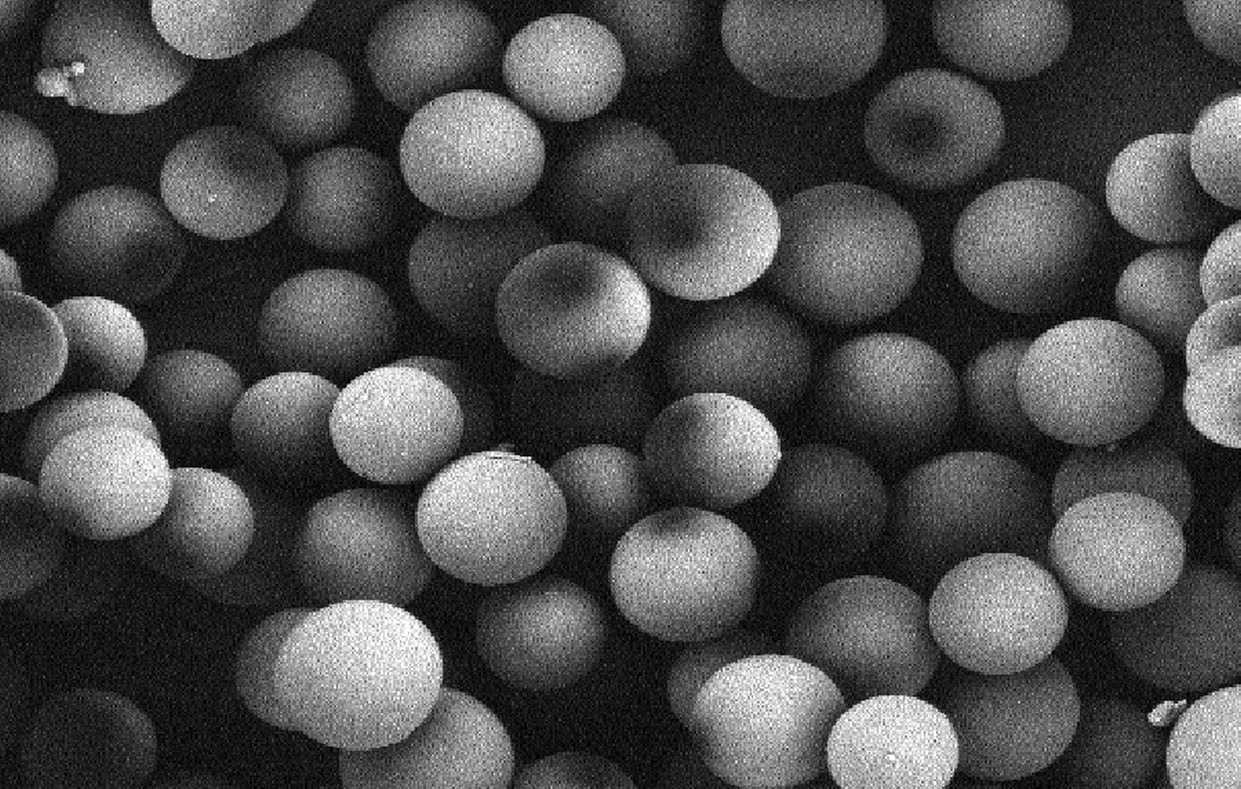

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank Shape

- Cylindrical

- Tank Size

- 200 litres

- Vacuum Tank Size

- 50 litres

- Air Accumulation Tank Size

- 200 litres

- Control panel type

- Pneumatic/Electric Control

- Integration with production cells

- Up to 16 cells connected

- Integration with vacuum pump systems

- Connected to cyclotrone vacuum pump