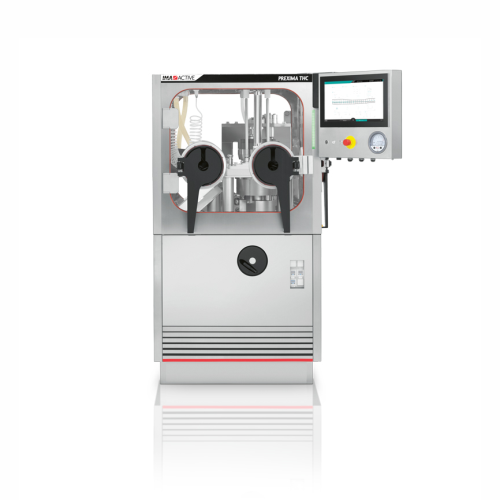

Tablet press for high containment environments

For handling potent compounds without compromising safety, a high-containment tablet press ensures operator protection and environmental compliance during tablet production.

Compresses and Contains High-Risk Pharmaceutical Tablets

The PREXIMA THC from IMA Group is a high-containment tablet press designed for pharmaceutical manufacturers dealing with potent or hazardous compounds. Specially engineered to compress tablets while ensuring operator safety, it features sealed doors, negative pressure zones, and glove ports for secure handling during operations. Its standout configuration flexibility, with a unique 8-station turret, supports both B and D tooling types, catering to a wide range of tablet sizes. The machine is ideal for producing paracetamol, ibuprofen, and anti-cancer drugs, among others. With a maximum output of 96,900 tablets per hour, the PREXIMA THC ensures efficient throughput. Equipped with the MAX corporate HMI, it enhances operator efficiency and process predictability. The machine’s robust construction ensures compliance with GMP standards and facilitates easy cleaning and maintenance with built-in cleaning ports. Its design supports integration into existing production lines, accommodating R&D, pilot, and high-speed production workflows.

Benefits

- Ensures safety with high-containment design for handling potent APIs.

- Flexible production capabilities accommodate various tablet sizes and formulations.

- Increases operational efficiency with high output of up to 96,900 tablets per hour.

- Enhances user experience and process reliability through intuitive MAX HMI interface.

- Facilitates compliance with GMP standards, ensuring regulatory alignment.

- Applications

- Supplements, Pharmaceutical tablets, Nutraceuticals, Biopharmaceuticals, High-containment pharmaceuticals

- End products

- Ibuprofen tablets, Biologic drugs, Vitamin d tablets, Fish oil capsules, Calcium supplements, Anticancer drugs, Multivitamin tablets, Hormone pills, Paracetamol tablets, Diabetes medication

- Steps before

- Milling, Granulation, Blend preparation

- Steps after

- Coating, Quality control, Packaging

- Input ingredients

- highly active pharmaceutical ingredients (HAPI)

- Output ingredients

- tablets

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Die type

- EU and TMS B+DDBBB

- Number of press stations

- 8 (4B + 4D)

- Maximum tablet diameter

- 16-25, 25, 16, 13 mm

- Maximum die filling

- 18 mm

- Maximum output

- 20, 400 - 96, 900 tablets/hour

- Revolution per minute

- 10-85 min-1

- Maximum pre-compression force

- 10 kN

- Maximum compaction force

- 60 kN

- Maximum installed power

- 6.9 kW

- Standard voltage

- 400 V (+/- 10%) – 50Hz

- Pitch circle diameter

- 180 mm

- Containment level

- Total high containment

- Flexibility

- High flexibility

- Integration capability

- Easily integrated with other equipment

- Safety features

- Sealed doors, negative pressure

- Operator accessibility

- Glove ports

- Cleaning method

- Manual cleaning, wetting with spray gun

- Operation type

- Suitable for R, D, pilot batches, production support

- Compression force

- Pre-compression and main compression

- Scale-up capability

- Similar to production machines

- Automation level

- MAX corporate HMI

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- High containment applications

- HAPI testing

- Machine configuration

- Special turret of 8 stations (4B + 4D)

- Die size

- 16-25 mm

- Maximum tablet diameter

- 16-25 mm

- Access method

- Glove ports

- Processing area containment

- Sealed doors, negative pressure

- Cleaning method

- Mobile spray gun and nozzle, manual cleaning

- Dimensions

- Not specified

- Turret Configuration

- 8 stations (4B + 4D)

- Integration with Other Equipment

- Easily Integrable

- HMI Type

- MAX new corporate HMI

- Access Method

- Glove ports

- Spray System

- Mobile spray gun and nozzle